Paper vs. Plastic

advertisement

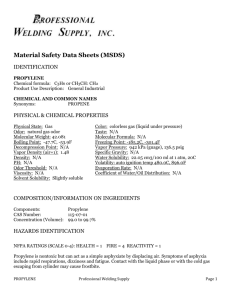

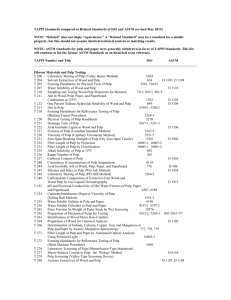

We are REALLY excited to talk paper vs. plastic! We love packaging! Paper vs. Plastic (C) Dordan Manufacturing Co. Inc. 2011 2 Paper feedstock • The primary raw materials used for paperboard production include wood chips, residual material from softwood dimensional lumber production, and recovered paper or paperboard products. • Additional inputs include chemicals for cooking liquors, additives such as starch and aluminum sulfate, sizing agents such as natural resins or synthetic sizing, and pigments and latex used for coatings (StoraEnso 2008). (C) Dordan Manufacturing Co. Inc. 2011 3 Pulp Conversion • First, the wood is broken down into cellulose fibers by chemically dissolving the lignin that binds the wood fibers together (chemical pulping). • After which, the slue is bleached, which serves to remove additional lignin from the fiber and lightens the pulp. • Common bleaching chemicals include chlorine dioxide and to alesser degree oxygen, ozone, hydrogen peroxide and enzymes such as xylanase. (C) Dordan Manufacturing Co. Inc. 2011 4 (C) Dordan Manufacturing Co. Inc. 2011 5 Paper Making • The papermaking process begins at the wet end of the papermaking machine where a layer of furnish consisting of about 99% water and 1% pulped fiber is dispersed evenly onto a continuously moving wire screen. • As the furnish moves through the process more and more water is removed and the paper is formed as it moves through a series of rollers. • Once the fiber mat is established on the screen, the remainder of the process smoothes the paper through calendaring and removes water using vacuums and presses, followed by final drying. (C) Dordan Manufacturing Co. Inc. 2011 6 (C) Dordan Manufacturing Co. Inc. 2011 7 Environmental Considerations • Pulp and papermaking requires large inputs of water, energy, chemicals, and wood resources, and produces various wastes and emissions that must be controlled or treated (U.S. DOE 2005). • Impacts on the environment can come from toxic and hazardous chemicals in air and water emissions, thermal and wastewater loading to natural waterways, odor–causing chemicals, air pollutants from combustion, and solid wastes (U.S. DOE 2005). (C) Dordan Manufacturing Co. Inc. 2011 8 Monomer Production Process • Both natural gas and petroleum are extracted from the earth for the production of plastic. • After extraction, these materials are transported to a gas processing plant or oil refinery where they are mixed with naphtha prior to the steam cracking process. • The extreme heat used in the process reduces or ‘cracks’ the molecule size of the natural gas or oil, forming lighter and more reactive hydrocarbons like ethylene and other monomers such as propylene. (C) Dordan Manufacturing Co. Inc. 2011 9 Polymer Production Process, Ex: PP • PP is typically formed in either liquid or gas phase propylene reactions. • Liquid propylene polymerization is carried out at pressure of about 365-510 psi and a temperature of 140-175 F. The process requires a reactor for the propylene monomer, hydrogen, and catalyst. • As the propylene monomer flows through the reactor, about 50% of it reacts and becomes polypropylene polymer. • The unreacted propylene is recycled back to the reactor. The polypropylene polymer is fed into a pelletizer to form pellets. (C) Dordan Manufacturing Co. Inc. 2011 10 (C) Dordan Manufacturing Co. Inc. 2011 11 Environmental Considerations • Oil and natural gas are the primary sources of energy for resin production; however, 10-15% of energy required for resin production is embedded in the polymer available for later recovery. • Carbon dioxide, methane and nitrous oxide are the major greenhouse gases emitted during resin production; however, over 75% of C02 emissions are related to fossil fuel use (Franklin 2007). (C) Dordan Manufacturing Co. Inc. 2011 12 Energy Required for Production of Common Packaging Polymers and Fiber-Based Packaging Materials (Franklin Associates, a Division of ERG, 2007 & U.S. DOE, 2005) 16 Million Btu per 1,000 lbs of material produced 14 12 10 8 6 4 2 0 HDPE LDPE LLDPE PP PET GPPS HIPS PVC ABS Fiber-Based Packaging Materials Material Type (C) Dordan Manufacturing Co. Inc. 2011 13 Overall Emissions/Waste Generated in Polymer Production (Franklin 2007. Brown and Cole 1993, APME 2005/6 & NAPCOR 2006) Lbs of waste generated per 1,000 lbs of resin produced 3000 2500 2000 Air Emissions 1500 Water Discharges Solid Waste 1000 500 0 PET HDPE PVC LDPE PP PS PLA Polymer Type (C) Dordan Manufacturing Co. Inc. 2011 14 TRI Data: Pulp and Paper Production Air Emissions and Surface Water Discharges (U.S. EPA 1996) 100,000,000 Lbs of Emissions/Discharges 90,000,000 80,000,000 70,000,000 60,000,000 Total Air Emissions 50,000,000 Surface Water Discharges 40,000,000 30,000,000 20,000,000 10,000,000 0 Industry (C) Dordan Manufacturing Co. Inc. 2011 15 Container and Packaging MSW Data, 2007 (U.S. EPA 2008) Aluminum 2% St eel 3% Wood 11% Paper & Paperboard Plast ic Glass 15% Paper & Paperboard 52% Glass Wood St eel Aluminum Plast ic 17% (C) Dordan Manufacturing Co. Inc. 2011 16 Container and Packaging % Recovery, (US EPA 2008) (C) Dordan Manufacturing Co. Inc. 2011 17 Paper vs. Plastic COMPASS LCA CS-002 plastic: 36.854 g of Polyethylene CS-002 corrugated: 96.544 g of Corrugated Terephthalate (PET) converted using converted using Production of Corrugated Thermoforming with Calendering Container (C) Dordan Manufacturing Co. Inc. 2011 18 (C) Dordan Manufacturing Co. Inc. 2011 19 High-five to you!!! For taking the time to learn about paper and plastic!