Fire hose and nozzle

FIRE HOSE CONCEPTS

During the early days of firefighting, the process of conveying water to a fire and applying it for extinguishment was a major problem. The first known used hose was the large intestines of animals and the most known was of the yak .

Over the years of civilization, crude types of fire hoses were developed yet there is no standard and satisfactory material produced until the 19 th century. Until that time, the most famous means of transporting water to a fire was the passing of buckets of water down a line of organized fire brigades and citizens called the “Bucket Brigade”.

FIRE HOSE CONCEPTS

Through the years of the rapidly changing needs for public safety, firefighting continues to deal with the current trends in combating destructive fires. Water, as one of the basic elements to support life and also the cheapest and most effective extinguishing agent continues to serve the fire department and also the people to prevent the spread of this destructive phenomenon.

FIRE HOSE CONCEPTS

Firefighters worldwide still put the fire out by moving water through a fire hose and directing its cooling effect to extinguish fire. A fire hose is absolutely essential to accomplishing our primary mission;

TO SAVE SAVABLE LIVES AND PROPERTIES from the damage or total loss caused by fires.

FIRE HOSE CONCEPTS

What is a Fire Hose?

Fire Hose, defined as:

a specially constructed lined woven-jacketed hose designed to withstand the hazards of the fire scene;

a type of flexible tube used by firefighters to carry water under pressure to a point where it is discharged; it must be water-tight, flexible and must have a durable covering or hose jacket (the outer covering of a hose and is also defined as a device clamped over a hose to contain water at a rupture point or to join damaged or dissimilar couplings); and

It is the most commonly used and abuse item it the fire service.

FIRE HOSE COUPLINGS

One of the greatest dilemmas faced by the fire service during at the turn of the century was that each fire department used different sizes and threads of fire hoses and its fittings.

There were once over 2,000 different fire hose threads and couplings and creating a major problem when different fire departments were to join conflagrations and major fire response. With this, it is impossible for some fire department pumpers to connect to fire hydrants and even other fire department pumpers.

As a result, needless loss of lives and properties because water cannot be effectively carried or moved to the fire.

FIRE HOSE COUPLINGS

During the late 1800s, fire service administrations began to recognize the problems associated with each fire agency using couplings of different threads. In 1873, the

International Association of Fire Engineers (now known as the International Association of Fire Chiefs) passed a resolution to set standards on fire hose screw threads.

As early as 1898, the National Fire Protection

Agency began drawing up thread specifications, not only on couplings but also in fire hoses, nozzles and accessories.

FIRE HOSE COUPLINGS

Developed dimensions for ten (10) coupling sizes (in inches) as to the year or its timeline:

1925 – 2 ½ , 3, 3 ½ , 4 ½

1935 – ¾ , 1, 1 ½

1955 – 4, 5, 6

1956 – standards for gaskets and grooves of all ten sizes were adopted

FIRE HOSE COUPLINGS

Agencies that adopted the Ten (10) Standards:

American Insurance Association

Association of Factory Mutual Insurance

Companies

International Association of Fire Chiefs

American Water Works Association

FIRE HOSE COUPLINGS

The thread used for the ten (10) sizes of threaded couplings is specified in NFPA 1963 -

Standards for Screw Threads and Gaskets for Fire

Hose Connection wherein this standard specifies the number of threads per inch for each of the couplings.

The standardized thread is called the

“ American National Fire Hose Connection Screw

Thread ” or NH or NST.

FIRE HOSE COUPLINGS

DIAMTER

INCHES MM

0.75

1.00

20

25

1.50

2.50

3.00

3.50

38

65

77

90

4.00

4.50

5.00

6.00

100

115

125

150

NUMBER OF THREADS

4

4

6

6

8

8

9

7 ½

4

4

FIRE HOSE COUPLINGS

What is a Fire Hose Coupling?

Fire Hose Coupling or simply coupling is defined as the fitting permanently attached to the end of a hose, used to connect two (2) hoselines together or a hose to such devices as fire nozzles, fire appliance, discharge valves, or hydrants.

FIRE HOSE COUPLINGS

Components of Fire Hose Couplings are generally alloys with varied percentages of:

Brass

Aluminum

Magnesium

FIRE HOSE COUPLINGS

Types of Couplings

Threaded Couplings

Sexless Couplings

Snap Couplings

FIRE HOSE COUPLINGS

Threaded Coupling

- a male and female coupling with a spiral thread

FIRE HOSE COUPLINGS

Parts of a threaded coupling

Shank (tail piece, bowl, shell) – serves as point of attachment to a hose

Higbee Cut – is a special type of thread design in which the beginning of the thread, which provides a positive connection between the first threads of opposing couplings, which tends to eliminate cross-threading

Higbee Indicator – marks where the higbee cut begins

Lugs – aid for tightening or loosening of connections

Swivel – permits connection of two section of hose without twisting the entire hose

FIRE HOSE COUPLINGS

Types of Lugs

Pin Lugs – are lugs that resembles like small pegs or nipple-like structure

Rocker Lugs – most commonly found lugs in the fire service

Recessed Lugs – are lugs that has shallow holes bored into the couplings

FIRE HOSE COUPLINGS

PIN LUG

ROCKER

LUG

FIRE HOSE COUPLINGS

Sexless Coupling

- there is no distinct male or female components, so both couplings are identical.

This coupling is normally found on large diameter hoses (LDH)

FIRE HOSE COUPLINGS

Two (2) kinds of Sexless Coupling

Quarter-Turn

Storz

FIRE HOSE COUPLINGS

Snap Couplings

– have both a male and female component that are snapped to both ends

FIRE HOSE COUPLINGS

Common Parts of a Fire Hose Coupling

Shank

Lugs

Swivel

HOSE CLASSIFICATIONS

By Use

By Construction

HOSE CLASSIFICATIONS

By Use

Attack Hose – any hose between the attack pumper and the nozzle to which it supplies water; any hose that is used to directly control and extinguish fire.

Relay/Supply Hose – is designed to move large volumes of water at low pressure and also has two category namely:

Medium Diameter Hose (MDH) - from 2 ½ “ - to 3”-diameter hose

Large Diameter Hose (LDH) - from 3 ½ “ to 6”diameter.

HOSE CLASSIFICATIONS

Intake Hose – is used to connect a fire department pumper or a portable pump to a nearby water source. This has two categories:

Soft-Sleeve Hose (soft suction) – used to transfer from a pressurized water source

Hard Suction Hose (hard sleeve) – used primarily to draft from an open water source

Fire Extinguisher Hose – is used on large extinguisher units that may be stationary, wheeled or vehicle-mounted. This has two groups namely

Conventional extinguisher hose (discharge pressure not more than 400 psi) and High-Pressure extinguisher hose (will withstand up to 1,250 psi)

HOSE CLASSIFICATIONS

By Construction

Another way to classify hose is according to the way it is constructed. Hose construction standards specify a number of construction and performance characteristics wherein these standards require that, all fire hose move water reliably and efficiently, be maneuverable, be durable and resist-kinking.

HOSE CLASSIFICATIONS

Four basic hose classification based on the methods of its construction:

Woven-Jacketed Hose

Rubber-Covered Hose

Braided Hose

Wrapped Hose

HOSE CLASSIFICATIONS

Woven – Jacketed hose.

- Used specifically for firefighting application where weight is a factor in maneuverability.

This has two general types:

Unlined hose – as the name implies, has no inner tube or liner. This type of hose tends its fabric when first charged to saturate and swell due to seepage but desirable. It has two classifications namely forestry hose and standpipe hose. Also called as single-jacketed hose.

Lined hose – is far more widely used type of fire hose and consists of more woven-fabric seamless jackets into which a rubber tube has been inserted and vulcanized, which makes it leakproof and reduces friction when water flows at a high velocity. This hose can withstand higher internal pressures and more resistant to damage caused by abrasion. Also referred to as double-jacketed hose.

HOSE CLASSIFICATIONS

Rubber-covered hose. As the term implies, has a rubberized cover that is mildew-proof and resists damage caused by abrasion and in contact with chemicals.

Braided hose. Is used in the manufacture of booster hose and fire extinguisher hose. This hose can withstand high internal pressure.

Wrapped hose. Primarily used in drafting or vacuum operations.

It is wrapped by several layers of diagonally cut (bias-cut) fabric around an extruded rubber tube and rubber compound and copper wire coiled between layers are applied to prevent collapse.

HOSE CLASSIFICATIONS

To better understand the relationship between the way a fire hose is constructed and used is shown in the table below:

WOVEN-JACKETED

Attack

MDH Relay-Supply

LDH Relay-Supply

Soft Sleeve

RUBBER-COVERED

Attack

MDH Relay-Supply

LDH Relay-Supply

Soft Sleeve

BRAIDED

Booster

Extinguisher

WRAPPED

Hard Suction

HOSE DAMAGES

Fire hose is a tool that is subjected to many potential sources of damage during fire fighting.

Like any other materials or objects, all are subject to wear-and-tear condition due to the nature of activity that fire fighters combat fires with the use of their tools and equipment.

HOSE DAMAGES

Different Types of Hose Damages and their prevention

Mechanical Damage

Thermal Damage

Organic Damage

Chemical Damage

HOSE DAMAGES

Mechanical Damage

- Are caused when an object contacts the hose along its length and cuts, abrades, tears or stresses the jacket and underlying materials and crushed or damaged couplings.

Recommended Practices for Prevention

Avoid laying or pulling hose over rough, sharp edges or objects

Use hose ramps or bridges to protect hose from vehicles running over it

Open and close nozzles, valves and hydrants slowly to prevent water hammer (force created by rapid deceleration of water under pressure)

Change position of bends in hose when reloading hose on apparatus

Provide chaffing blocks to prevent abrasion to hose when it vibrates near the pump

Avoid excessive pump pressure on hose lines

HOSE DAMAGES

Thermal Damage. Is caused when exposure to excessive heat or cold which weakens the fabric layer, melts or freezes the rubber linings.

Recommended Practices for Prevention

Protect hose from exposure to excessive heat or fire when possible

Do not allow hoses to remain in any heated area after it is dry

Use moderate temperature for drying. Warm Air or Air dry is better than hot air

Keep the outside of the woven-jacketed fire hose dry

Run water through hose that has not been used for some time to prolong its life

Avoid contact in close proximity with vehicle exhaust systems

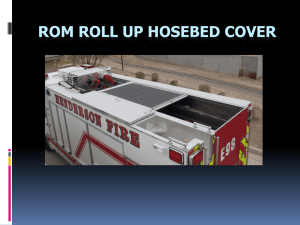

Use hose bed covers on apparatus to shield the hose from the sun

HOSE DAMAGES

Organic Damage. This causes decay and consequent deterioration of the hose due a parasite called fungus or otherwise known as mold or mildew.

Recommended Practices for Prevention

Remove all wet woven-jacket hose from the apparatus after a fire and replace with dry hose

Remove, inspect, sweep and reload woven-jacket hose if it has not been unloaded from the apparatus during the period of 30 days

Exercise woven-jacket hose every 30 days and run water through it every 90 days to prevent from drying and cracking of the rubber lining

Ventilate all areas where hose is kept

Cover hose beds with water repellent covers to keep loads dry during inclement weather

HOSE DAMAGES

Chemical Damage. Is caused when hose is exposed to petroleum, oil, acids, alkali’s, paints and runoff water from a fire.

Recommended Practices for Prevention

Scrub hose thoroughly and brush all traces of acid contacts with a solution of baking soda and water. Baking soda neutralizes acids

Remove hose periodically from the apparatus, wash with plain water, and dry it thoroughly

Avoid laying hoses in the curb or gutter where vehicles have been parked and might drop chemicals due to leakage

Dispose of hose properly if it has been exposed to hazardous materials and cannot be decontaminated

PROPER CARE AND MAINTENANCE

Three (3) methods of caring and maintaining fire hoses

Washing

Storing

Drying

PROPER CARE AND MAINTENANCE

Washing Hose

- Most laborious, time-consuming job that can be simplified by using devices or manually done by fire fighters. Use mild soap or detergent on the hoses and brush thoroughly with stiff bristled brush to remove dust and dirt. Rinse the hose thoroughly.

Machines / devices used on washing/rinsing/draining hose

Cabinet-type hose washing machine

Jet Spray device

PROPER CARE AND MAINTENANCE

Storing Hose

After the hose has been cleaned or dried, it should be rolled and stored in suitable hose racks, hose towers or improvised hose storage.

The area must be kept clean and well- ventilated.

If on hose beds, must be covered with waterrepellent covers

PROPER CARE AND MAINTENANCE

Drying Hose

This must be done according to manufacturers’ instructions and must be dried using warm air to avoid moisture on the rubber linings.

HOSE APPLIANCE AND TOOLS

A complete hose layout for fire fighting purposes includes one end of the fire hose attached to or submerged in a source of water and the other attached to a nozzle or similar discharge device.

These devices are grouped into two:

Hose Appliances

Hose Tools

HOSE APPLIANCE

HOSE APPLIANCE

Is any piece of hardware used in conjunction with the fire hose for the purpose of delivering water

Kinds of Hose Appliance

Valves

Valve Devices

Fittings

Intake Devices

HOSE APPLIANCE

Valves. Controls the flow of water in hoselines, hydrants and at pumpers.

Types and usage

Ball Valves. Used in pumper discharges and gated wyes

Gate Valves. Used to control the flow from a hydrant

Butterfly Valves. Used on large pump intakes.

Clapper Valves. Used in Siamese appliance to allow one intake hose to be connected and charged before the addition of more hoses

HOSE APPLIANCE

Valve Devices. Increase or decrease the number of hoselines operating at the fireground.

Types of Valve Devices

Wye Appliance. Divides a line of hose into two or more lines. Often gated so that water being fed up to into the hoselines may be controlled at the gate.

Siamese Appliance. Wye and Siamese appliance are often confused because of their close resemblance. This appliance consists of two or more hoselines that are brought into one hoseline or device. This device is commonly used to overcome the problems caused by friction loss in hose lays to cover a long distance flow. Popular on LDHs.

HOSE APPLIANCE

Water Thief Appliance. This is a variation of the wye appliance. It is intended to be used on a 2 ½ - inch or larger hoseline, usually near the nozzle so that the hoselines may be used as desired from the layout.

Large Diameter Hose Appliance. This type often necessitates the use of special appliances to distribute the water near the final destination of the hoseline. These devices are sometimes called portable hydrants, manifolds, phantom pumpers, or large diameter distributors.

Hydrant Valves. These valves are used when a hose lay is made from the water-supply source to the fire scene.

HOSE APPLIANCE

Fittings

Are used for connecting hoses of different sizes and thread types.

Types of Fittings

Adapter. A fitting for connecting hose couplings with dissimilar threads but with the same inside diameter.

Ex: double male, double female

Reducer. This type of fitting is used to reduce a larger diameter coupling to a smaller coupling.

Elbows. Changes the direction of flow.

Hose Caps. Closes male couplings.

Hose Plugs. Closes female couplings.

HOSE TOOLS

HOSE TOOLS

These are used in conjunction with hose lines.

Kinds of Hose Tools

Hose Rollers. Prevents mechanical damage of hose when dragged over sharp surfaces such as roof edges and windowsills. This is secured with a C-clamp and rope.

Spanners, Hydrant Kits, and Rubber Mallets.

Spanners, tighten and loosens hose couplings; Hydrant Kits are combination of spanner and a pentagon-shaped wrench for opening hydrants; and Rubber Mallets is used to strike the lugs to tighten or loosen intake hose couplings.

HOSE TOOLS

Hose Clamps. Stops the flow of water in a hoseline in order to prevent charging the hose during hose-lay operations; to allow replacement of burst sections without shutting down the supply line; to allow extension of hose line; and allow advancement of charged hoseline up stairs.

Types of Hose Clamps

Screw-Down

Press-down

Hydraulic Press

Hose Strap, Hose Chain, Hose Rope. One of the most useful tools to aid in carrying or handling charged hoselines is a hose strap, hose chain or hose rope. These devices used to carry and pull fire hose, but their primary value is to provide a secure means to handle pressurized hose when applying water, and secure hose in ladders and other fixed objects.

HOSE TOOLS

Hose Ramps. Helps prevent injury to hose when vehicles cross it.

Hose Jacket. When firefighting conditions are not possible to change a line when ruptured, this encloses the portion to prevent leakage of both pressure and water.

Chaffing Block. Devices that used to protect fire hose where the hose is subjected to rubbing from vibrations from the intake hose or pumper vibrations

SUPPLY HOSE LAYS

SUPPLY HOSE LAYS

Forward lay. A method often used when the water source is a hydrant and the pumper must stay in location.

Reverse Lay. A method wherein the pumper must first go to the location so that a size up can be made before laying a supply line.

Split Lay. Refers to any one of a number of ways to lay multiple supply lines.

SPECIAL HOSE OPERATIONS

These are special operations that are not done routinely but nevertheless, it is important to know.

Connecting Hard-Suction Hose

Connecting Soft-Sleeve Hose

Connecting Hose to a Portable Monitor

Kinking Hose to Shut Down a Charged Line

Retrieving a Charged “Wild-Line”

Securing a Hoseline to a Ground Ladder

Hoisting a Hoseline

Passing a Hoseline Upward

For Rescue

FIRE NOZZLES

Fire Nozzle or simply nozzle is defined as a device that directs water from the hose to the fire. It forms the water into a fire stream and controls the stream so that fire can be extinguished.

Parts of a Nozzle

Shutoff Valve provides a means of not only opening and closing the nozzle but a means to control the amount of flow of water through the tip

Tip is the component that forms the streams

FIRE NOZZLES

Kinds of Nozzles

Solid Stream Nozzles. The oldest type of nozzle in the fire service and it can penetrate a mass of burning material when a fire is deep seated.

Fog Nozzles. As to the name itself, produces a fire stream made up of small droplets of water that leave the tip in a spray or “fog” pattern.

Exposure Nozzles. This is designed to protect a building or object from heat generated by a nearby building that produces a fan-shaped stream called “water curtain” approximately 35 feet wide and two stories high.

Applicator Nozzles. This are designed to direct a water stream directly over the surface of a burning object.

Master Stream Devices. Moves larger quantities or volume of water when such size and intensity of fire grows. This includes monitors, deluges, turret pipes and ladder pipes.

FIRE STREAMS

Fire streams can be defined as a stream of water or other extinguishing agent after it leaves a fire hose and nozzle until it reaches a desired point.

Fire streams intended to reduce high temperatures from a fire and provide protection to firefighters and to exposures through the following methods:

Applying water or foam directly to the burning material to reduce its temperature

Applying water or foam over an open fire to reduce the temperature so that firefighters can advance handlines closer to effect extinguishment

Reducing high atmospheric temperature

Dispersing hot smoke and fire gases from a heated area by fire using fire stream

Creating a water curtain to protect firefighters and property from heat

Creating a barrier between a fuel and a fire by covering with a foam blanket

FIRE STREAMS

Extinguishing properties of water

Cooling Effect

Smothering Effect

Expansion Capability

FIRE STREAMS

Several Characteristics of Water that are extremely valuable for fire extinguishment

Water is readily available and inexpensive

Water has greater heat-absorbing capacity than any other common extinguishing agents

Water changing into steam requires a relatively large amount of heat

The greater the surface area of the water exposed, the more rapidly heat is absorbed

FIRE STREAMS

Water Fire Stream Patterns

Water fire stream is identified by its size and type. The size refers to the volume of water flowing per minute.

Classifications of Fire Streams as to its size

Low-Volume Stream discharges less than 40 gpm (160 L/min) including those fed by booster nozzles

Handline Stream discharges from 40 to 350 gpm (160 to 1,400

L/min)

Master Stream discharges from more than 350 grpm. This are also large-volume fire streams

FIRE STREAMS

Different Types of Streams

Solid Stream is a fire stream produced from a fixed orifice. It has the ability to reach areas that other streams might not reach and minimizes the chance of steam burns to firefighters.

Fog Stream is a fire stream composed of very fine water droplets. The design of most fog nozzles permits the adjustment of the fog tip to produce different fire stream patterns.

Broken Stream is a steam of water that has been broken into coarsely divided drops.

FIRE STREAMS

Different Fire Stream Patterns

For Defense

O pattern

For Offense

Arrow Head Pattern / Inverse Arrow Head Pattern

Brushing Pattern or Sweeping Pattern

Cross Pattern

T Pattern

I

Pattern

END OF PRESENTATION

THANK YOU VERY MUCH