Lecture series 12 - Civil and Environmental Engineering | SIU

advertisement

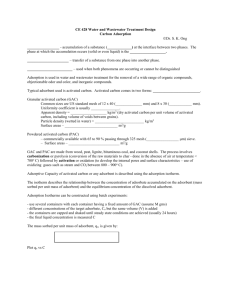

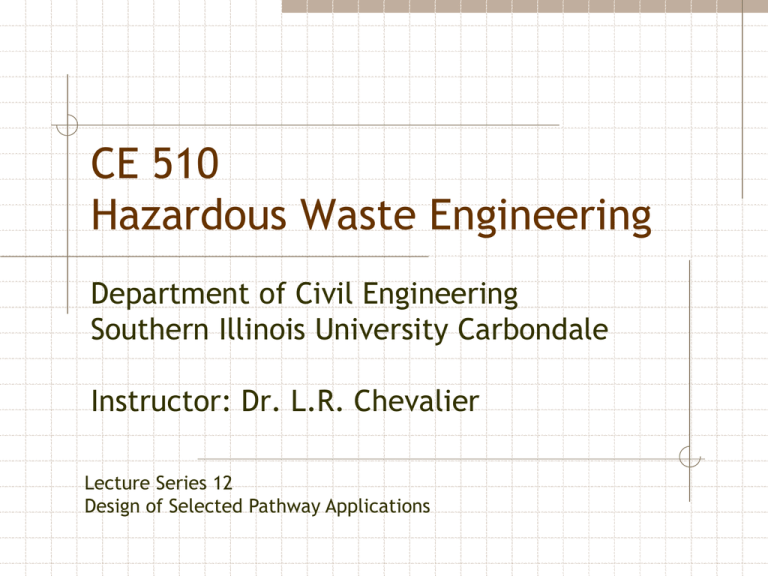

CE 510 Hazardous Waste Engineering Department of Civil Engineering Southern Illinois University Carbondale Instructor: Dr. L.R. Chevalier Lecture Series 12 Design of Selected Pathway Applications Course Goals Review the history and impact of environmental laws in the United States Understand the terminology, nomenclature, and significance of properties of hazardous wastes and hazardous materials Develop strategies to find information of nomenclature, transport and behavior, and toxicity for hazardous compounds Predict the behavior of hazardous chemicals in surface impoundments, soils, groundwater and treatment systems Assess the toxicity and risk associated with exposure to hazardous chemicals Application of scientific principles of hazardous wastes to their design, management, remediation and treatment Sorption by GAC Has along history of use as a treatment for municipal, industrial, and hazardous waste streams Is a relatively non-specific adsorbent and is effective for removing many organic and some inorganic contaminants from liquid and gaseous phases Sorption Design Application GAC Contactors Design Procedures:- outcomes of design effort are: Mass and volume of carbon necessary to treat a given volume of water before regeneration is required System configuration (number of columns in series Proposed dimension of the system Sorption design Application C/Co vs. service time C/Co Time in operation Sorption design Application GAC Design Methods Mass loading or Isotherm Data method Uses loading values (isotherm data) for specific contaminants Does not account for non-equilibrium conditions Operating line method Accounts for mass transfer and diffusion into pores within the carbon Finite Element Method Accounts for mass transfer, dispersion and competitive sorption by different contaminants Schematic of a GAC system Source: USEPA Pilot column Studies Effective procedure for designing full-scale GAC contactors Relative contaminant concentration is measured as a function of time Water to be treated is pumped through a series of columns that are 5-10 cm in diameter and 2-3 m deep. Contaminant concentration is measured as a function of time, and the data are converted to relative contaminant concentration. System configuration of pilot scale GAC evaluation Analysis of Pilot System Data Most common method is the graphical analysis of the breakthrough curve. Bed Depth-Service Time (BDST) analysis is used in drinking water and industrial hazardous waste treatment Horizontal lines are drawn through each curves at C/Co=0.10 and C/Co=0.90 which represent break-through and exhaustion points respectively. Analysis of Pilot System Data Analysis of Pilot System Data The horizontal distance between the exhaustion line and breakthrough line is defined as the height of the adsorption zone (D). t = ax + b Analysis of Pilot System Data From the fit of the data, the constants a and b may be analyzed further to develop parameters that can be used for full-scale design. The slope, a is defined as ℎ 103. 𝑁 𝑎 = 𝑠𝑙𝑜𝑝𝑒 = 𝑚 𝐶𝑜. 𝑣 Where, N = sorptive capacity of the carbon = 𝑚𝑎𝑠𝑠 𝑜𝑓 𝑐𝑜𝑛𝑡𝑎𝑚𝑖𝑛𝑎𝑛𝑡 𝑟𝑒𝑚𝑜𝑣𝑒𝑑 (𝑘𝑔) 𝑣𝑜𝑙𝑢𝑚𝑒 𝑜𝑓 𝑐𝑎𝑟𝑏𝑜𝑛 (𝑚3) Co = influent contaminant concentration (mg/L) 𝑣 = superficial velocity through column [m3/(m2-h)] Analysis of Pilot System Data The intercept, b is defined as 103 𝐶0 𝑏 = 𝑖𝑛𝑡𝑒𝑟𝑐𝑒𝑝𝑡 ℎ = ( )x ln[ − 1] 𝐾.𝐶𝑜 𝐶 Where, K = the adsorption rate constant [m3/(kg-h)] C = contaminant concentration at breakthrough (mg/L) The minimum column depth to obtain an acceptable effluent concentration, the critical bed depth, is found from the intercept of the C/Co=0.1 line where t=0. 𝑚 1 𝑎𝑑𝑠𝑜𝑟𝑝𝑡𝑖𝑜𝑎𝑑𝑠𝑜𝑟𝑝𝑡𝑖𝑜𝑛 𝑣𝑒𝑙𝑜𝑐𝑖𝑡𝑦 = ℎ ℎ 𝑎(𝑚) 𝑑(𝑚) 𝑒𝑥ℎ𝑎𝑢𝑠𝑡𝑖𝑜𝑛 𝑡𝑖𝑚𝑒 ℎ = 𝑚 𝑎𝑑𝑠𝑜𝑟𝑝𝑡𝑖𝑜𝑛 𝑣𝑒𝑙𝑜𝑐𝑖𝑡𝑦 ( ) ℎ 𝑘𝑔 1 𝑘𝑔 2 𝑐𝑎𝑟𝑏𝑜𝑛 𝑒𝑥ℎ𝑎𝑢𝑠𝑡𝑖𝑜𝑛 𝑟𝑎𝑡𝑒 = . 𝐴 𝑚 . 𝜌( 3) ℎ ℎ 𝑚 𝑎 𝑚 System Scale-Up The total number of columns in series (based on the height of the 𝐷 adsorption zone), n, is: 𝑛 = + 1 𝑑 Where, D = height of the adsorption zone (m) d = height of the pilot columns (m) The loading rate on the pilot columns is calculated as: 𝑉 = 𝑄𝑝 𝐴𝑝 This loading rate may be used to calculate the area of the full𝑄𝑓 scale columns as: 𝐴𝑓 = 𝑉 Where; V = column loading rate [m3/(m2-day)] Qp = pilot column flow rate (m3/day) Ap = cross sectional area of the pilot columns (m2) Qf = full-scale flow rate (m3/day) Af = area of full-scale contactor (m2) Class Example Solution Spreadsheet