tiw-ppt-02-firemo-1.4-1.5

advertisement

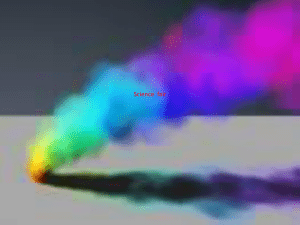

1.4. FIRE MODELING THEORY An Educational Program to Improve the Level of Teaching Risk-Informed, Performance-based Fire Protection Engineering Assessment Methods DJ Icove & AE Ruggles Department of Nuclear Engineering 1 1.4 Fire Modeling Theory • Fire development in compartments is often divided into phases depending on the dominant processes at any given stage of development. • Ignition is dictated by the characteristics of the fuel item being ignited (i.e., ignition temperature, geometry, orientation, and thermophysical properties) and the strength of the ignition source. NUREG 1934 Scenarios 3 1.4 Fire Modeling Theory (Con’t) • Once the flames are sustained on a burning fuel item, a smoke plume develops; transporting mass and heat vertically as a result of the buoyancy of the smoke. 4 5 1.4 Fire Modeling Theory (Con’t) • The plume will entrain air as it rises, causing the smoke to cool and become diluted; as a result, the quantity of smoke being transported will increase with increasing elevation. • After a smoke plume strikes the ceiling, the smoke travels horizontally under the ceiling in a relatively thin layer, referred to as a ceiling jet. • As the ceiling jet travels, the smoke cools with increasing distance from the plume impingement point, in part because of air entrainment into the ceiling jet as well as heat losses from the ceiling jet to the solid ceiling boundary. 6 1.4 Fire Modeling Theory (Con’t) • The aspects of fire behavior that may be of interest in such analyses include: – Rate of smoke production – Rate of smoke filling – Properties of the ceiling jet – Properties of the HGL – Target response to incident heat flux via either thermal radiation or convection 7 Rate of smoke production • Smoke is defined as a combination of the gaseous and solid particulates resulting from the combustion process, plus the air that is entrained into the flame and/or smoke plume. • The rate of smoke production at a particular height in the plume is the combination of the generation rate of combustion products and air entrainment rate into the flame and/or smoke plume between the top of the fuel and the height of interest. • Since air entrainment rate greatly exceeds the generation rate of combustion products, the correlations used to estimate the rate of smoke production are usually taken from experimental research on entrained air. 8 Rate of Smoke Filling • The rate of smoke filling is dependent on the rate of smoke production, the heat release rate, floor area and height of the space, and time from ignition. • For a fire with a steady heat release rate, the rate of smoke filling in a compartment will decrease with time due to a decrease in the smoke production rate, which decreases as the height available to entrain air decreases when the HGL deepens. 9 Properties of the Ceiling Jet • The ceiling jet transports smoke and heat horizontally away from the region of plume impact with the ceiling. • The response of ceiling-mounted fire detectors or sprinklers is governed primarily by their interaction with a ceiling jet. • The temperature and concentration of smoke in a ceiling jet is principally dependent on the height of the space, distance between the impact point of the smoke plume and the ceiling, and the heat release rate of the fire. 10 Properties of the HGL • As smoke and heat are transported to the HGL via the smoke and fire plumes, the properties of the HGL will change. • The principal properties of interest include the depth, temperature and gas concentrations in the HGL. • The magnitude of the properties depends on the heat release rate of the fire, geometry of the space, ventilation openings (permitting material from the HGL to leave the space, providing air to the fire, and/or causing a stirring action), yields of combustion products, and the elapsed time after ignition. • These changes can be tracked by considering the conservation of energy, mass, and species relative to 11 Target response to incident heat flux via thermal radiation or convection • The targets’ temperature will increase as a result of receiving heat via either thermal radiation or convection. • Radiation heat transfer is dependent on the intensity of thermal radiation emitted by a source, the size of the source, and the proximity of the target to the source. • For this application, the flame height, the portion of heat released from the fire as radiation, and the distance separating the target from the flame are the dominant parameters. • Convection heat transfer occurs whenever the target is submerged in the smoke plume or HGL. 12 Range of Fire Models 13 1.4.1 Algebraic Models • Algebraic models may be standalone equations found in literature or may be contained within spreadsheets (such as the NRC’s FDTs), and can help give a general understanding of one of the fire environment phenomena. • These equations are typically closed-form algebraic expressions, many of which were developed as correlations from empirical data. • In some cases, they may take the form of a firstorder ordinary differential equation, and, when used properly, can provide an estimate of fire variables, such as HGL temperature, heat flux from flames or the HGL, smoke production rate, depth of the HGL, and the actuation time for detectors 14 1.4.1 Algebraic Models (Con’t) • Algebraic models are helpful because they require minimal computational time and a limited number of input variables. • When applying the results of the algebraic models, users need to be aware that the development of most equations involved assumptions to simplify the analysis. • Other than for very simple situations, algebraic models are useful primarily as screening tools (i.e., to provide a rough approximation to an analysis, perhaps as a check of an aspect of the results of the computer-based models), and are also applicable when only one phenomenon can be treated in isolation: for instance, plume or ceiling jet correlations are not applicable if there is a significant HGL unless they are modified to account for this effect. 15 1.4.2 Zone Models • A zone models calculate fire environment variables using control volumes, or zones, of a space. • The zones correspond to a cooler lower layer and an HGL. 16 1.4.2 Zone Models (Con’t) • The fundamental idea behind a zone model is that each zone is well-mixed and that all fire environment variables (temperature, smoke concentration, etc.) are therefore uniform throughout the zone. • Conditions in each zone are calculated by applying conservation equations and the ideal gas law. The variables in each zone change as a function of time and rely on the initial conditions specified by the user. • It is assumed that there is a well-defined boundary separating the two zones, though this boundary may move up or down throughout the simulation. 17 1.4.2 Zone Models (Con’t) • Zone models are most applicable in situations involving simple geometries or where spatial resolution within a compartment is not important. • The preparation of input for a zone model, the computation time, and the amount of output data generated are slightly more extensive than a simple algebraic model; however, the overall computational time cost is still low. 18 1.4.3 CFD Models • A CFD model is often useful when trying to determine fire variables at a specific location or when there are geometric features that are expected to play a significant role in the results beyond what is calculated in a zone model approximation. • A typical CFD model consists of a preprocessor, a solver, and a postprocessor. CFD models can provide a detailed analysis in both simple and complex geometries. CFD models essentially apply a series of conservation and state equations across multiple cell boundaries in a space. • The number of cell boundaries depends on the mesh size, which breaks the geometry into three-dimensional subvolumes called cells. Solutions to partial derivatives of the conservation equations are updated as a function of time within each numerical grid cell, with the solutions in all cells, collectively describing the fire environment within the geometry at the cell resolution. 19 1.4.3 CFD Models (Con’t) • CFD models have much better spatial fidelity than zone models, being able to distinguish conditions in one part of the space from another. • Because of the appreciable amount of time and effort required to apply CFD models as compared to zone models or algebraic models, CFD models are generally applied when: – Spatial resolution is important, either relative to the locations of fuel packages or targets. – Large compartments relative to the fire size are involved. – Compartments have complex geometries, flow connections, or numerous obstructions in the upper part of the compartment. – Large numbers of compartments are within the area of interest and the presence of each compartment is expected to affect the fire environment in the area of interest. 20 1.4.3 CFD Models (Con’t) • While CFD models provide a detailed analysis of a space, they are costly to create, simulate and maintain. The input files created in the preprocessing stage require a significant effort to create. The user must understand the code syntax and the implications and assumptions embedded in the model. • A firm understanding of fire dynamics is important in providing input data that is relevant to the application. Most CFD models have default values that must be recognized and adjusted as necessary if the simulation is going to be accurate. • The relevance of the default values needs to be confirmed for any application. User manuals and technical references for each CFD model outline such values and may provide recommended ranges for the parameters. 21 1.4.4 V&V • The use of fire models to support fire protection decision making requires a good understanding of their limitations and predictive capabilities. NFPA 805 states that fire models shall only be applied within the limitations of the given model and shall be verified and validated. • Verification is the process of determining that a model preserves the laws of science and math, thereby assessing whether it was “built” correctly. In this assessment, the theoretical basis of the model is reviewed to confirm that the scientific and mathematical foundation of the model is correct, that is, that the laws of physics and chemistry are upheld and proper numerical techniques are employed. 22 1.4.4 V&V (Con’t) • Validation is the process of determining that a model is a suitable representation of the real world and is thus capable of reproducing the phenomena of interest. • Validating a model requires that the output of subroutines or the entire model provide predictions that compare reasonably well with experimental data. • NRC RES and EPRI conducted a project for V&V of the five selected fire models described in Sections 2.3.1 through 2.3.5 that may be used to support RI/PB fire protection and implementation. • The results of this project were documented in NUREG1824, Verification and Validation of Selected Fire Models for Nuclear Power Plant Applications. 23 1.5 NFPA 805 An Educational Program to Improve the Level of Teaching Risk-Informed, Performancebased Fire Protection Engineering Assessment Methods 24 1.5 NFPA 805 Fire Modeling Applications • The NFPA 805 requirements associated with fire modeling are organized in two sections: – Section 4.2.4.1 describes requirements for the implementation of a performance-based fire modeling analysis. – Section 2.4.1.4 describes the requirements associated with the analytical fire modeling tools selected for the analysis. 25 1.5.1 Requirements Associated with the Implementation of a Performance Based Fire Modeling Analysis • NFPA 805 Section 4.2.4.1 describes the process to follow when using fire modeling to address variances from deterministic requirements (VFDRs). • VFDR is used in the fire protection community within the commercial nuclear industry to refer to plant conditions that deviate from deterministic requirements of NFPA 805 Section 4.2.3. 26 NFPA 805, Section 4.2.4.1 – Variances From Deterministic Requirements (VFDRs) • Identify Targets (NFPA 805 § 4.2.4.1.1) • Establish Damage Thresholds (NFPA 805 § 4.2.4.1.2) – Damage or ignition temperature – Damage or ignition incident heat flux • Determine Limiting Conditions (NFPA 805 § 4.2.4.1.3) • Establish Fire Scenarios (NFPA 805 § 4.2.4.1.4) – Maximum Expected Fire Scenario (MEFS) – Limiting Fire Scenario (LFS) • Protection of Required Nuclear Safety Success Paths (NFPA 805 § 4.2.4.1.5) • Operations Guidance (NFPA 805 § 4.2.4.1.6) 27 NFPA 805 28 1.5.2 Requirements Associated with the Selected Analytical Fire Models • NFPA 805 Section 2.4.1.2 describes the requirements for the use of fire models, which include: – The use of fire models acceptable to the authority having jurisdiction (i.e., the US Nuclear Regulatory Commission) – The application of fire models within their range and limitations. Section 2 of this document provides guidance on ensuring the model is within the range of limitations and what steps are necessary if the application is outside existing V&V data ranges 29 1.5.2 Requirements Associated with the Selected Analytical Fire Models • NFPA 805 stipulates that the fire models used shall be verified and validated. In the context of this application, the specific analytical capabilities within the fire model need to be verified and validated. • Model capabilities not invoked in specific calculation are outside the scope of this requirement. • NUREG-1824 (EPRI 1011999) is an example of a verification and validation study for fire models specifically developed for NPP applications. 30 31