Preparation Of DPR & How To Monitor The Construction Works On

advertisement

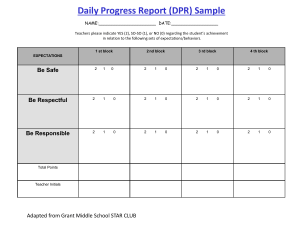

Preparation Of DPR And How To Monitor The Construction Works On Technical Aspect. Preparation of DPR DPR is the based document for planning and implementing the project. DPR indicates the technical and financial strategies to be adopted for implementation. Preparation of DPR DPR is broadly comprised of following things. Project background. Project definition, concept and scope Project cost Project institution framework. Project financial structuring Project phasing Project O & M framework and planning Project financial viability / sustainability. Project benefits assessments. Project Background It narrates the necessity and aim of the project. Existing status of the physical infrastructure. Base line information of users. Project definition, concept and scope The project concept comprises of several issues like :- Land Environment impact assessment Environment management plan Rehabilitation and Resettlement Details of surveys and investigation Disaster related risk assessment and countermeasures. Project Cost The project cost should clearly indicate covering all following factors: Land acquisition / site development Physical infrastructure component-wise cost Environmental compliance cost Rehabilitation & resettlement cost Cost of survey & investigations Cost of shifting utilities Cost of consultancy services Finance / interest cost Contingency Project Institution framework. The DPR needs to provide : Role of institutions involved in the Project A Roles / responsibility matrix Innovative approaches for better coordination between ULB and state government department. Manner of undertaking construction works Involvement of the construction agency in the O & M activities Project Institution framework. Area of involvement of the private sector in the construction phase of feasibility study, engineering design, specialized surveys, construction works, supervision consultants, Quality Assurance Consultants or any other assignments Brief description of strategy for the overall works program including tender process. Project Financial structuring DPR must indicate the composition of fund. Central Government. State Government. ULBs Loan component, Private Investment etc. will have to be shown in the DPR. Project Financial structuring Private participation can be utilized in ULB or State share. Private contribution can be recovered against O & M in the shape of user charges. The billing and collection of user charges can be entrusted with the Private Agencies. Project Financial structuring Linking construction with O & M performance contract could provide the advantage of operational cost efficiency. Private sector financing in the project is a well accepted approach under JnNURM as it curtails the financial burden on Govt. and Municipal fund. Project Phasing Project Activity Schedule to be indicated. Schedule for tendering. Schedule for State and ULB contribution Schedule for all clearances. Schedule for shifting utilities Schedule for implementation of project components Project O & M planning The DPR should indicate :- The institution to be engaged in the O&M Existing system of billing and collection. Brief analysis of the key issues and obstacles . Scope of private entity in O&M. The requirements of manpower, energy, spares etc. for O&M with proposed additional requirement. Tariff model, existing rate for all categories and forecast growth over the next 20 years. Project Financial viability / sustainability . The DPR is to provide information in Municipal level. Cash flow : A complete cash flow covering the last 5 (five) years and projections for the next 20 (twenty) years. An assessment of the annual impact of the project on the Municipal finances. Project Financial viability / sustainability Debt situation assessment : Debt schedules and terms for all debt taken. Debt service coverage ratio Debt-equity ratio for the project and the ULB Other financial information : Credit rating details. Project Benefits assessments DPR is to provide the following : List of benefits (both social & economic) Benefits are to be assessed on project outcomes and project outlays covering impact on citizen. Project benefits assessments List of adverse impacts on following aspects: Pollution, environmental distortions Reduced green cover Reduced access to any specific user segments Supply interruptions etc. Displacement of inhabitants Disruption in livelihood / reduced employment Possible haphazard development around / adjacent project site areas Preparation of DPR on Municipal Solid Waste Landfill Selection of Landfill site Criteria : Lake or Pond : No landfill should be constructed within 200m of any lake or pond. River : No landfill within 100 m of a navigable river or stream. Flood Plain : No landfill within a 100 year flood plain. Highway : No landfill within 200 m of the right of way of any highway. Trees and berms are used to screen the landfill site. Selection of Landfill site Habitation : A landfill site should be at least 500 m from a notified habitated area. A zone of 500 m around a landfill boundary should be declared a No-Development Buffer Zone. Public Parks : No landfill within 300 m. Wetlands : No landfill within wetlands. Ground water : No landfill in areas where water table is less than 2 m below ground surface. Selection of Landfill site Airports : No landfill within 5 miles from Airport Operational Area. Water Supply Well : No landfill within 500 m of any water supply well. Unstable Zone : A landfill should not be located in potentially unstable zones such as landslide prone areas. Buffer Zone : A landfill should have a buffer zone around it Land fill DPR on landfill will have following contents Introduction Present Status Site Characteristics Landfill Design Facilities Land fill Design Features and Site Plan Landfill Construction Landfill Closure Monitoring Requirement Costing Landfill Introduction : This is the introductory brief of activities to be performed for landfill. Also this is a review of landfill development process to ensure a landfill is constructed, operated and maintained in environmental friendly manner. Land fill Present Status : It narrates the present generation of solid waste, collection system, transportation and dumping method. Landfill Site Characteristics : It is the description of proposed land, its area, topography, access facility, climate, rainfall, temperature, humidity, ground water status, surface water and drainage system, soil properties etc. Landfill Design Facilities The essential basic steps for landfill design are Landfill sizing Site layout Landfill layout Leachate management Landfill gas management : Landfill construction 1st layer – 50 cm thick compacted soil 2nd layer – Geo-synthetic clay liner 3rd layer – 1.5 mm HDPE Geo-membrane Landfill construction 4th Layer – 30 cm thick gravel. The gravels should be smooth, and round of 12 – 15 mm in size. Leachate collection system of perforated HDPE leachate collection pipe embedded in this gravel layer Landfill construction 5th layer – Geo-textile for filtration. 6th layer – Finally a 300 mm thick soil on the Geo-textile as a protective layer Leachate will go to leachate treatment plant for reduction of BOD, COD and suspended solids. Daily waste is leveled, compacted and covered with fresh earth to give a pleasing appearance and also to prevent odours. Landfill Closure Waste will have to be graded to the necessary stable slopes. 1st layer - 200 mm thick gravel to release gas through gas vents. 2nd layer - 600 mm soil. 3rd layer - 1 mm thick HDPE liner to control water leaching into soil layer. 4th layer - 150 mm thick gravel for drainage. 5th layer - Geo-textile to keep the soil layer separated. 6th layer - 450 mm thick soil for vegetation. Monitoring Requirement Ground water quality monitoring within 50 mtr. periphery of landfill site shall be periodically monitored. Ambient air quality monitoring will have to carried 4 (four) times in a year around the site. Portable methane detection units are available for the purpose. The air quality must be monitored for 15 (fifteen) years after the closure of the landfill. Surface water monitoring around the site is also necessary. Cost For all activities to be performed detailed estimate on the basis of engineering details will have to be prepared to determine the project cost. How To Monitor The Construction Works On Technical Aspect Construction Monitoring It is the process to monitor and control the activities associated with initiating, planning, executing, and closing a project. Problems during execution should be identified in a timely manner for immediate corrective measures. Construction must be monitored and measured regularly to identify deviations from the plan. Construction Monitoring Free site must be ensured before any work is taken up. Site of construction is to be identified to ensure flawless layout of the work. Mobilization of manpower, materials, equipments and resources is most essential. Construction Monitoring Monitoring is needed to ensure proper management on following issues : Cost Quality Risk Construction Monitoring Cost Management : It is necessary to perform cost control process of influencing the factors that create changes to the basic cost to ensure that the changes are beneficial and according to exact requirement of the work. Construction Monitoring Quality Management : It is necessary that the quality of the work is properly ensured in terms of materials and workmanship Quality Management Quality of materials will have to be ensured before work is taken up : Bricks : Bricks shall be sound, hard, homogenous in texture. Bricks shall have a minimum crushing strength of 105 kg/sq.cm. Bricks should have ringing sound if struck Brick absorbing more than 20% of its dry weight after 24 hrs. immersion shall be rejected. Quality Management Sand is the fine aggregate, which shall pass through IS: sieve designation 4.75 mm, leaving a residue not more than 10%. Sand should be collected from local river beds Sand shall not contain more than 8% of silt. It should be clean, hard and sharp. Quality Management Stone aggregate : This shall be broken from good hard stone boulder and shall be free from soft, friable, thin, elongated or laminated pieces. This shall be roughly cubical in shape and shall be clear and free from dirt and any other foreign matter. Quality Management Steel : Presently we use TMT (Thermo Mechanically Treated) steel of various brands. BIS Certification Marking should be checked in each bundle of bars before use. Quality Management Cement : Net weight of each bag of cement shall be 50 kg. Cement stored for over 6 (six) months shows signs of deterioration or contamination and should be tested before use. OPC cement and PPC cement are generally used for construction. OPC conforms to IS: 269-1989 and PPC conforms to IS: 1489-1991 Quality Management Concrete consistency : The quantity of water to be used for each mix of 50 kg. cement shall not be more than 34 ltr. for 1:3:6 mix, 32 ltr. for 1:2:4 mix., 30 ltr. for 1:1:2 mix. For vibrated concrete the limit specified may be suitably reduced. Quality Management Curing : Curing of concrete shall be done after 24 hrs. of laying with moist gunny bags, sand etc. for a minimum period of 7(seven) days. Concrete should not be disturbed by further construction during the curing period. Risk Management Four steps to risk management are : Risk Identification Risk analysis Risk management planning and Risk review Risk should be reviewed periodically with the related persons so that it can be faced and tackled on time Thank You