What is 5S?

advertisement

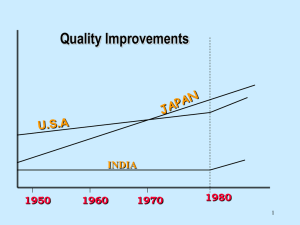

LEAN LEAN 5S Launching for JU JANUARY 2013 1 What is 5S? The concept of 5S originated in Japan It forms the backbone of the workplace organization in the Toyota Production System 5S is a series of steps for individuals and teams to arrange their work areas to create and maintain an organized, clean, and high performance workplace 5S is the foundation for continuous improvement, zero defects, cost reduction, and a safe work area What does 5S stand for? Sort Simplify Sweep Standardize Self-discipline Step 1 SEIRI (Segregate and Eliminate – SORT) Clearly distinguish needed items from unnecessary items and eliminate what is not needed. Step 2 SEITON (Arrange and Identify – SIMPLIFY) Arrange needed items so that they can be found quickly by anybody. Step 3 SEISO (Daily Cleanup Process – SWEEP) Create a spotless workplace. Step 4 SEIKETSU (Constant Adherence to the First Three Steps and Safety – STANDARDIZE) Standardize cleanup activities so that these actions are specific and easy to perform. Create and maintain a safe work environment. Step 5 SHITSUKI (Achieve Habitual Compliance – SELF-DISCIPLINE) Promote adherence to maintaining a high performance, high quality and safe work environment. Use visual performance measurement tools. FOCUS on ROOT CAUSES of waste and efficiency and work to eliminate them! STEP 1 Seiri Sort رتب, نظم, عاشر,فرز Organization Dispose What is Sort? • The first step in 5S • Originally called ‘Seiri’ in Japanese • Distinguish between the necessary and unnecessary items in a given area • Then remove the unnecessary Requires setting clear sorting criteria and procedures and allocating resources and time to get it done right with minimal risk to operations Why Sort? The removal of waste and unnecessary clutter from the work space helps us avoid the following: The lab/office/field site becomes increasingly cluttered, crowded and hard to work in o Lockers, shelves, and cabinets used to store unneeded items put ‘walls’ between employees Excess inventory and equipment which are costly to maintain o Unneeded items and equipment make it difficult to improve workflow Unsafe work conditions o Environmental hazards Have you seen this before? Can you work here? How do we manage our storage areas? Before Sort After Sort Key Questions - Sort Before you go to the next stage, consider the following Was management involved in the process? Did they ‘walk their talk’ and be an example? Do employees understand the reason for ‘Sort’? Has the planned 5S area been completely sorted? Have all rubbish items been properly disposed? Have legal and environmental regulations/requirements followed in disposing and storing the sorted items? Was a list created for all special/expensive items that were removed or sold? Has the area been adequately cleaned? STEP 2 Seiton Simplify Set in Order يسر,بسط Neatness 30 sec retrieval What is Simplify? • The second step in 5S • Originally called ‘Seiton’ in Japanese; can also be translated as ‘Set in order’ or ‘Straighten’ • Arrange items so they can quickly and easily found by anybody • Everything has its place and in its place • Safety as well as motion economy determines the location of items Identify key areas to simplify, encourage team solutions, and align with business goals and priorities Why Simplify? • You can do things quicker and easier • Time spent looking for items is reduced or even eliminated • Errors in item retrieval are reduced • Increased safety due to items not being left in walkways etc. • Easier stock maintenance due to increased visibility Motion waste Searching waste Transport waste Waste of human energy Waste of excess inventory Waste of defective products Unsafe conditions Think of a pit crew at a F1 race, every item is positioned to error proof and speed the process, and to eliminate all wasted motion: 7 Seconds to change 4 tires, fill the gas tank, wash the helmet, and give the driver a drink. Key Areas to Simplify • Lay-out or floor plan • Location of ‘parts’ (e.g. files, consumables, bottles, references, equipment) • Inventory of consumables and supplies • Usage and storage of files and information Simplify Example • Bottles are ‘prepared’ and ready for use • Stored in a designated area that keeps it safe and easily accessible • Shelves are labelled to identify items quicker • Visually easier to see if supply needs to replenished Key Questions - Simplify Before you go to the next stage, consider the following Has the team reviewed the workflow to make activities more efficient (and safe!) Has the team arranged and labeled the equipment, tools, files, consumables, supplies, etc. so that anyone (even new staff) can find and locate what they need without difficulty? Have the people in the area been made aware/trained of the implemented changes? Are the changes in accordance with local safety/environmental regulations or standards? STEP 3 Seiso Sweep Shine تطهير,تنظيف Cleaning DIY What is Sweep? • The 3rd stage of 5S • Originally called ‘Seiso’ in Japanese it can also be translated as ‘Shine’. • Emphasizes removal of dirt, waste paper and materials, and clutter from the work area for good. • Careful and systematic cleaning will help spot potential problems. Cleaning in this case is, in fact, careful checking. Identify root causes of clutter, make cleaning part of job, train people, and implement a housekeeping plan What happens if we don’t Sweep? • Errors and ‘abnormal conditions’ are more difficult to see compared to a well-lit and clean environment • Puddles of chemicals and water cause slipping and injuries • Machines not maintained regularly which increases break down frequency and affects consistency of results • Increases risk of contamination which affects quality of results • Filthy work environments lower employee morale Admin Area Before Sweep After Sweep Key Questions - Sweep • Has the team identified target areas for ‘sweeping’? • Have SOPs/ work instructions/ and other related documents revised to incorporate the new cleaning activities? • Has a housekeeping schedule (daily/monthly/yearly) been implemented? Are people responsible adequately trained? • Do the relevant stakeholders agree with the new cleaning activities? Is there someone responsible to ensure the cleaning activities are implemented and maintained? STEP 4 Seiketsu Standardize قاس, إختبر بمعيار,عاير Transparency of Storage What is Standardize? • The 4th stage of 5S • Originally called Seiketsu in Japanese and can be translated as ‘Systemise’. • It ties the first 3 stages (Sort, Simplify, Sweep) together • Changes are made clear and understood by all Determine level of standardization, develop new or update existing guidelines, use visual management tools Why Standardize? • Easier to train new employees • Less room for errors and scrap • Work area is more organized; making it easier to work faster and with less error • Work area is safer • Better consistency in products and services provided to customers Everyone should agree on the way to do things, document it, and actually do it. Key Questions - Standardize • Have procedures/work instructions created or updated based on the key changes introduced in the previous stages? • Do people now share a common approach to getting things done in the work area (particularly those related to changes introduced in the previous changes)? • Is there a system by which procedures/labels/schedules, etc. are regularly reviewed and improved in the future? STEP 5 Shitsuke Self-discipline Sustainenance انضباط النفس On Becoming a culture What is Self-discipline? • Although this is listed as the 5th step in 5S, Self-discipline starts from DAY 1 of implementation • Originally called ‘Shitsuke’ in Japanese and also translated as ‘Sustain’ • As the term it implies, it means that the 5S mentality is ingrained in everyday work life and procedures. Make 5S part of day-to-day work, reward good efforts, build on initial improvements Why Self-discipline? • If this is not done, things will go back to the old ways • Self-discipline ensure the 5s cycle continues • Like the lab at the right, after the initial sorting, simplifying and sweeping, it means having to do it all again after some time With commitment, the gains are sustained Without commitment, the first four Ss quickly falls apart Key questions – Self-discipline • Have the 5S benefits adequately communicated to key stakeholders? • Are the people adequately trained to carry-out the 5S activities? • Is there a system in place to monitor and follow-up 5S tasks? • Was a 5S ‘audit’ conducted? Were the results communicated and corrective actions implemented? • Were the people who helped/championed 5S recognized? • Are measures in place to ensure work areas and processes are regularly evaluated and improved? What does 5S stand for? Sort Simplify Sweep Standardize Self-discipline Step 1 SEIRI (Segregate and Eliminate – SORT) Clearly distinguish needed items from unnecessary items and eliminate what is not needed. Step 2 SEITON (Arrange and Identify – SIMPLIFY) Arrange needed items so that they can be found quickly by anybody. Step 3 SEISO (Daily Cleanup Process – SWEEP) Create a spotless workplace. Step 4 SEIKETSU (Constant Adherence to the First Three Steps and Safety – STANDARDIZE) Standardize cleanup activities so that these actions are specific and easy to perform. Create and maintain a safe work environment. Step 5 SHITSUKI (Achieve Habitual Compliance – SELF-DISCIPLINE) Promote adherence to maintaining a high performance, high quality and safe work environment. Use visual performance measurement tools. NOW is the BEST TIME to START PHASE 1 Preparations * Understanding philosophy and benefits of 5S * Organize 5S Working Committee * Train 5S facilitators and practitioners 2 Dean’s Official Announcement * Publicize 5S organization and assignments by area * Promote 5S with banners, posters and newsletters * Organize basic 5S training programs for all colleagues 3 PREPARATION ROLL-OUT 11 MONTH STEP 12 1 2 MAINTENANCE AND UPGRADING 3 4 5 6 7 8 9 10 11 12 1 2 3 → → Big Cleaning by All Colleagues * Organize a full-day of ‘Big Cleaning Day’ twice a year * Organize small groups who are responsible for assignments in divided areas of the company’s premises. * Provide enough cleaning tools and materials * Implement a division-wide big cleaning for one day * Big cleaning includes the elimination of unnecessary items and wastes 4 Initial Seiri * Establish a Disposal Standard for unnecessary items * Organize a full-day of Seiri activity twice a year * Everyone concentrates to identify and stratify unnecessary items for elimination * Unnecessary items that cost a lot should be evaluated so as to prevent the occurrence of such waste 5 Daily Seiri, Seiton and Seiso * Seiri: Throw away things that are not needed and not being used * Seiton: Improve locations and methods for storing things so that searching time is minimized * Seiso: Set up a daily cleaning schedule for the creation of a healthy and comfortable workplace * Motivate colleagues to come up with creative improvements 6 Periodic Audits on 5S * Conduct a 5S audit regularly by auditors * Award groups and individuals for their contributions * Organize study tours to other companies doing 5S * Organize 5S inter-divisional competition to sustain the program → 5S Committee • • • • Sponsor: Vice President Advisor: Dean Champion: Mr A Sub-Champions: - Mr B - Mr C - Mr D - Mr E • 5S Auditors: Mr F, Mr G Big Cleaning Day: Friday, 6th Nov 09 Store Room and File Cabinet Other Common Area Own Cubicle (all Staff) Issues: • Big black trash bag • Disposal area • Disposal Policy on obselete asset • Collaborate with cleaners • Contact waste buyers THE END THANK U