Applicability, Quality Control and Quality Assurance in

advertisement

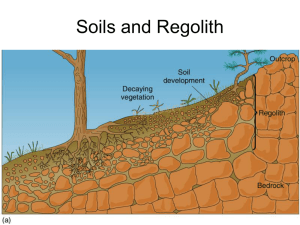

Applicability, Quality Control and Quality Assurance in Ground Improvement Presented by Kulbir Singh Gill, Associate Prof. GNDEC, Ludhiana INTRODUCTION Unfortunately, soils are made by nature and not by man, and the products of nature are always complex(Karl Terzaghi 1936). The advancement in geotechnical engineering has provided many alternatives to deal with the problems encountered during soil investigation for the site selection of a particular project. Since the safety of lives and property are at stake, it is important to consider the geotechnical merits or demerits of various sites before the final decision is taken for that project. Moreover risks and costs needs to be evaluated. Contd. Due to the lower value of land to population ratio in India, it is utmost important to utilize any type of land available for construction. So keeping in view the above stated problem , different types of ground improvement techniques are adopted to make the weak soils suitable to meet the minimum requirement for any particular project. The various types of ground improvement techniques which are commonly used are: Contd. Improvement by vibro compaction Ground improvement using vibro replacement Ground improvement using deep soil mixing Ground improvement using permeation grouting. Improvement by increasing effective stresses. Improvement by admixtures. Geotechnical reuse of waste materials. Weight reduction. In this presentation only the applicability, quality control and quality assurance are covered. Applicability of the Vibro Compaction This technique is used to increase the bearing capacity of foundations and to reduce their settlements. Another important application is to mitigate the liquefaction potential in earth prone areas by densification of sand. Vibro compaction can be used to support any type of projects from embankment to chemical plants. Mainly this technique depends on the granular soil to be compacted. So far the deposits down to 65m have been improved by vibro compaction. Quality Control and Quality Assurance In general quality control programme is divided into categories, namely monitoring of compaction parameters and post compaction testing. The compaction parameters(depth and power consumption) are monitored using computerized systems. Post-compaction testing is performed to ensure that the specifications are met. Dynamic penetrometer tests(DPT),standard penetration tests(SPT) and cone penetration tests(CPT) is most popular post compaction test. At least one week cooling period must be given after the compaction in order to dissipate the excess pore water pressure to initial level before compaction. Limitations Vibro compaction technique is most effective for sands and gravels with fines less than 15 to 20% as shown in Figure Applicability of Ground Improvement using Vibro Replacement : The unique characteristic of the vibro replacement technique is that it is able to treat a vide range of weak soils from loose silty sands, soft marine clays, ultra soft silts and clay from mine tailings, garbage fill to peaty clays. The various types of structures which can be supported soil improved by vibro replacement are simple earth embankments, modern expressway embankments, bridge approaches, high speed railway embankments, marine and offshore structures, seaport/airport facilities, power plant structures, chemical plants, sewerage treatment plants and large storage tanks. The basic aim of vibro replacement is to increase the stability and bearing capacity of weak soil as well as to restrict the settlement. In earthquake prone areas it has also been used to mitigate liquefaction potential. Quality Control and Quality Assurance in Vibro Replacement In vibro replacement method, quality control monitoring consists of monitoring of column construction parameters and post construction testing. During construction, the main parameters of the construction process(depth, vibration energy during penetration and compaction processes and stone consumption) are recorded continuously as a function of time, thus ensuring the production of a continuous well compacted column. The performance of vibro stone columns is assessed using plate load tests which should be carried out by loading a rigid steel plate or cast in situ concrete big enough to span one or more columns and the intervening ground. Contd. . In contrast to the more familiar load tests in piles, both the column and the tributary area of soil around the column are loaded. In addition, the performance of the treated soil to support the intended structure is evaluated based on the results of instrumentation such as rod settlement gauges, inclinometers, etc. Limitations: Vibro stone columns are not suitable in liquid soils with very low undrained shear strength, because the lateral support may be too small. In general, the technique is applied to structures with high order of settlement tolerance. Applicability of Deep Soil Mixing The technology of deep soil mixing can be implemented on wide range of weak and problematic soil types such as loose sands, soft marine clays, ultra soft slimes, weak silty clays and sandy silts. Typical applications include foundation s of embankment fill for roads, highways ,railways and runways; slope stabilization, stabilization of cuts and excavations(Topolinicki,2004 and Raju et.al., 2005). The DSM technology can also be used for vibration reduction applications and to partially reduce water paths for water tight applications. Quality Control and Quality Assurance of Deep Mixing Soils. For both wet and dry deep soil mixing ,quality control during execution is important to ensure uniform improvement of soil and to ascertain that the required amount of binder has been mixed uniformly over the entire depth of treatment . For this purpose, the mixing units are equipped with automated computerized recording devices to measure the real-time operating parameters such as depth of mixing tools, volume or weight of binder used etc. After allowing for sufficient curing period(typically,3 to 4 weeks), the mixed columns can also be tested using single/group column plate load tests, unconfined compressive strength tests on cored/backflow samples, visual examination of exposed columns, etc. Applicability of Ground Improvement using Permeation Grouting This type of grouting is very effective in sands gravels, coarser size materials(e.g .boulders and cobbles) and fissured, jointed and fractured rock formations. The technique is well suited for a wide variety of applications, such as foundation retrofitting, dam rehabilitation, subsidence and liquefaction mitigation etc. Applications can be categorized into the following general areas, site improvement, foundation rehabilitation, excavation support, ground water control.(Karol, 1990). Applicable soil types for Permeation Grouting Limitations Permeation grouting is not suitable in cohesive soils such as silts and clays. The other types of grouting techniques such as fracturing grouting and jet grouting can be considered to improve such soils. Applicability of Ground Improvement using Weight Reduction This technique involves reduction of weight applied to a soft compressible soil by the use of light weight fill material. The over all benefits gained from the light fill materials include reduced settlement, increase in slope stability and reduced lateral earth pressure on retaining structures. A key benefit is material’s high resistant to earthquake effects (the low unit weight results in lower seismic inertial forces). Light Weight Materials used for Ground Improvement Fill Material Source/Process Dry Unit Weight (Kg/m3) Wood fibres Sawed lumber waste 550-960 Shredded tyre Mechanical cut tyre chips 600-900 Calm shells Dredged under water deposits 1100-1200 Expanded shale Vitrified shale or clay 600-1040 Fly ash Residue of burned coal 1120-1400 Air-cooled slag Blast furnace material 1100-1500 Flowable fill Foaming agent in a concrete matrix 335-770 Geofoam Block moulded expanded polystyrene 12-32 Quality Control and Quality Assurance in Ground Improvement using Weight Reduction: The key issues with the weight reduction method of ground improvement are to placement of the light weight material and its durability and long-term performance. Well planned laboratory experimentation is needed to optimize the use and performance of light weight materials . Durability can be checked in the laboratory. Limitations Some of the material are susceptible to various types of problems after their placement in the field, e.g. geofoam can easily catch fire also deterioration can occur gasoline spills or insect borrowing. Continued crushing and knitting of the shells during compaction of the shells under the influence of vehicular traffic may reduce the drainage potential of embankment. Thus resulting in ponding of water at the surface and also it may reduce the frictional angle of the material, thus increasing the lateral pressure on the supporting structures. Applicability of Ground Improvement using Admixtures. Use of various admixture such as lime, cement, fly ash and furnace slag are well understood to the geotechnical engineers. But recently several environmental friendly enzymes have come into the market such as Fujibeton, Terrazyme and Renolith etc. These materials are yet to gain popularity in the field of ground improvement. The fujibeton material, developed in Japan, is climatically stable material and suitable for stabilization of all types of soils. Basically, the product is an inorganic polymer that chemically binds with all compounds when blended with OPC in 1 to 3% by weight. The blended mix is called fujibeton mix. The technology can be advantageously used in the construction of low volume roads where aggregates are not available at economical rates but also for all type of soil conditions . Fujibeton improves CBR of the subgade and does not create shrinkage cracks and is there for highly effective for clayey soils. With fujibeton, a high dry density is obtained with minimum compaction, therefore simple and small equipments are sufficient for construction. Terrazyme Terrazyme is a natural, non-toxic, environmentally safe, bio enzyme product that improves engineering properties of soil. The function of terrazyme is to minimize absorbed water in the soil for maximum compaction, which decreases the swelling capacity of soil particles and reduces permeability. The application of terrazyme enhances weather resistance and increases load bearing capacity of soils especially in clayey soils. This will provide cost effective both in the initial construction cost and maintenance cost of roads. Terrazyme technology is also advantageous in:considerable improvement in the soil CBR.Minimum loss of gravel due to erosion or abrasion by the traffic preserving original transverse section. Renolith Renolith is a polymer based chemical, which is environmentally friendly and facilitates the bonding of soil mass. The soil-cement with renolith has a high modulus of elasticity and can disperse the wheel loads very effectively. It is a semi rigid material. This type of construction does not require surfacing for low volume roads, since the base course is stabilized. It is expected to give good performance with longevity and reduces maintenance costs and almost dust free environment Quality Control and Quality Assurance in Ground Improvement using Admixtures The design concept is based on the optimization of admixture quantity for stabilization based on unconfined compressive strength or CBR test results determined on the given soil for different proportions of soil and admixtures. After the construction ,core can be taken and tested for unconfined compressive strength in the laboratory. Limitations: Limited research is available with soil cement and these admixtures in abroad but similar studies are yet to be carried out in India Thanks