Measuring and

Managing Shrink

October 2012

WIS Share Forum

KPMG LLP

Inventory Accuracy and Shrink

Identification, quantification and remediation of shrink is a challenge

‒ Shrink in on the rise

‒

Requires a holistic approach

‒

Traditional tools and focus are not enough

‒

Growing percentage of shrink is not associated with physical loss

‒

Limited shrink reporting

‒

Root causes of shrink are not well understood

‒

Framework to identify, quantify and remediate shrink

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

1

Shrink is on the Rise

‒

Rising inventories

‒

SKU proliferation

‒

Method of inventory valuation

‒

Master data issues

‒

Definition of cost

‒

Misaligned processes and systems

‒

Major system replacement or upgrades

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

2

Requires a Holistic Approach

Stores

In-transit

Physical Shrink

Distribution Center

Vendor

Warehouse

Transaction Processing

Systems

Shrink

Interfaces

Conversions

Master Data

Inventory Management

Paper Shrink

Processes

Global Imports

DC, Cross Docks and Stores

Returns

Account Payables

Accounting

Inventory Accounting

Inventory Control

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

3

Traditional tools while effective are not enough

Examples of Shrink Tools

Human Resource Program

Integrity Screening

Pre-Employment

Screening

Employee Awareness

ILLUSTRATIVE

Training/Job Aides

Shrink Improvement Program: “Quick Reference Guide”

Electronic Article Surveillance (EAS) Tagging

Deters Shoplifters and Detects External Theft

Electronic Article

Surveillance

(EAS) System

A selected group of products receive EAS tags. When these products are scanned at the cash register,

the EAS tags are deactivated. If the EAS Tags are not properly deactivated, an alarm signals [at the

antennas (pedestals)] that store employees must respond to.

Deter

PROPER TAGGING PROCEDURES

Background Checks

Loss Prevention

Shrink Binder

Newsletters/Videos

Detect

Monitoring Program

Mgmt/Compliance Reporting and Score carding

Daily Transaction Reports

Cash Handling

Refunds, Voids, etc.

Shrink Management Tool – Store Profile

Control

High Risk Product Program

Improve Supply Chain Processes

(DCs, Receiving, Storage, Handling, etc.)

In-store display

Anti-theft Fixture

Source Tagging

One EAS Tag Should be Placed:

On all items with the shelf tag symbol !!

Securely on the item where the surface is flat, dry and clean

On the back or bottom of the item

On the paper or cardboard part of battery packages

EAS tags can be placed on all magnetic media such as video, audio and film

Shelf Tags: Look for !! and !!M Here

EAS Tags Should Not be Placed:

On items with the shelf tag symbol !!M (those items have Source Tags from manufacturers)

Placing an EAS tag over a Source Tag deactivates both tags

Over product names, instructions, prices, warnings, ingredients, expiration dates, call numbers

or other key information (color, size, etc.)

Directly to metal: Includes batteries and boxes with aluminum wrapping inside

Directly on vinyl or leather (adhesive can damage the merchandise)

On microwavable items (tags can damage the microwave)

On a product if the EAS tag has a pink/red dot on it (these tags are deactivated)

EAS Tag: Front

EAS Tag: Back

PROPER RESPONSE TO EAS ACTIVATIONS (ALARMS)

Store employees must RESPOND TO and TRACK all EAS antenna (pedestal) alarms

A member of store management must respond (manager, assistant manger or key cashier)

If store management is unavailable to approach the customer, only ONE employee responds

Every time the system alarms, record the event in the EAS Activation Log Notebook

Steps when ALARM SOUNDS as a customer EXITS the store

1. Approach customer in a non-threatening manner: smile, be friendly and discreet - Never yell, run at or embarrass customer

2. Use this apologetic approach: “Excuse me, apparently we have failed to deactivate your inventory control tag (use this term

in front of customers.) Will you please allow me to deactivate the tag?” (Hold out hand for purchase - NEVER grab the bag or

merchandise)

3. Once the customer hands you the bag, step away from the system so the alarm stops

4. With the bag in hand, step completely THROUGH the antennas

5. If the bag sets off the alarm return to the cash register and CHECK THE RECEIPT for the items in the bag

If the item is LISTED ON THE RECEIPT:

Apologize for the inconvenience, deactivate the product and neatly re-bag the items

If an item is NOT LISTED ON THE RECEIPT:

? Ask the customer: “Since we failed to correctly ring up and deactivate a product, would you like to purchase this item?”

? After this check, take the purchase and walk through the system with the customer following you

? If the alarm does not respond when you walk through but does respond when the customer walks through: the

customer may have an unpaid product that is not properly deactivated

? If the customer admits to shoplifting and if they agree to sign a report: complete an External Loss/Theft Incident ReportForm 1171 and also provide the shoplifter with a copy of the Civil Demand Notification

Upon completion of Form 1171: West Coast stores fax a copy to (541) 475-8091and East Coast to (818) 787-4201

Please post fax numbers in the office (please keep fax numbers current- may change)

If the shoplifter is uncooperative, has a shoplifting record and/or does not have an ID: Call police (at your discretion)

Issue the shoplifter a Barring Notification if you believe he/she is a “threat to the store”

6. If the bag does not set off the alarm, or the customer did not have a bag when the alarm initially went off

Have the customer walk through the antennas: If the alarm goes off, the customer may have an unpaid product that is not

properly deactivated

If the customer admits to shoplifting follow Rite Aid’s Policy and Procedure on Shoplifting (above)

Steps when ALARM SOUNDS as a customer ENTERS the store

Schlage Shield for Wallet

1. Approach the customer in the same fashion as above

2. If the customer has a bag, ask if they would like you to deactivate a tag another

store might have missed

3. Ask if the customer has a key access card (one type could set off the EAS system)

If so, check if the card sets off the alarm and give them a Schlage Shield Card to avoid future system activations

Beepers, cell phones, credit cards and keys DO NOT set off the system

Shrink Mgmt Tool

Compliance Reporting

Exception Reporting

HRP Identification

Risk Analysis Model

High Risk Stores

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

4

Inventory Accuracy and Shrink

Growing percentage of shrink is not associated with physical loss

‒

Reported shrink (known shrink) is understated and a significant cause of

controllable shrink.

‒

Inventory valuation is subject to volatility in reporting based on the cost

compliment calculation, retail valuation for center store and cost based valuation

for perishables

‒

Master Data – often retailers do not have a single item master database which

drives several issues contributing to shrink including item setup errors, system

update errors, and late cost changes

‒

Receiving Accuracy - Receipt accuracy is likely contributing to shrink and out of

period adjustments

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

5

Process Shrink

‒

‒

How effective are your physical inventory processes?

Do you see significant margin or inventory valuation swings in your fresh

departments

‒

Do you have detailed process maps related to inventory movement?

‒

Are your processes, controls and systems in synch?

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

6

Strengthening basic fundamentals

Implementation timeframe: 6 months or

less

Vendor

Compliance

Vendors do not oversship against the purchase order quantity

Vendor sends accurate ASN’s

Verify receipt to the PO quantity

Accurate

Receiving and

Payables

Input accurate receiving information on a timely basis

Pay for what you receive – order

Balance direct import GL inventory and liability accounts

Minimize changes to PO quantities

PO Controls

ASN Accuracy

Implementation

timeframe: 6

months or

greater

Manual

Receiving

Controls

Close out old purchase orders in warehouse system

Company X translates EDI transactions accurately into the ASN tables

Improve and govern ASN compliance with vendors and ODP systems

Receive shipments accurately against the purchase order

Minimize key strokes

Receive against the purchase order

Next Steps

Match net receipt transactions with purchase order and invoice (3 way match)

Automation of journal entries in direct import accounting

Reengineer financial controls for vendor settlements, store receipt adjustments and returns

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

7

System Shrink

‒

Have you recently implemented any new systems?

‒

Does you organization have a current systems Map?

‒

Are automated balancing routines established between systems?

‒

Who is responsible and are error logs worked daily?

‒

Do business owners have to sign off on all system design changes?

‒

Has your organization completed transaction testing?

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

8

Inventory System Interface Diagram

Legend

Pay Systems

DB2 Table

Receive/Ship/

Transfer

Systems

General

Ledger

System

Retek

Real-Time Data Interface

Batch Job Data Interface

POM

Mainframe

GSS

Global

PO

Updates

PO Modeling

PO Updates

Auto

Replenishme

nt Program

RDF

RMS

Oracle

Dashboard

WDTS

NonCode

Item

Data

Procurement

Systems

Vendor

Portal

Manual SKU

Strategy

Settings

Data

Transfer

Systems

SKU/P

O

Activit

y,

Alerts

Customer

Sales/Return

s Systems

Item Cost and List

New Item Data,Price Data

Cost Changes,

Forecasts

Item

Maintenance

Systems

Message

Queue

Paid

Reporting Data

Manual PO Creation

Auto PO Creation from RDF Data

Sales

Sales/Returns Accounting

System

Store Receipts, Transfers, Adjustments

RTV Data

Receipts & Adjustment Data

Customer Orders

Warehouse

Inventory

System (WIV)

COS/Sector

Routing

System

STS

Order Fulfillment Data

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

Sales/Returns

Customer Orders

POS

Item Data,

DC OnData

Sales/Returns

hand Qs

WMS –

Distribution

Centers

Receipts/Shipment Data

Item Data

WMS –

Cross Docks

PO/Item Data

Sales/

Return

s

RTV Data RTV System

AOPS

Vendor Payment Data

Store

Inventory

System (SIV)

Receipt J/Es

Store Inventory

System Web

Front-End

G\L Data

DB2

Non-Code Item Data

SITran

License Plate Data

Sales/Returns Data

RCC System

Integral A/P

Non-Code Item Data

Vendor Receipts/Rec’t Adjustment Data

Non-Receipt/Sale Transaction Data

PeopleSoft

G/L

PeopleSoft

A/P

PeopleSoft

9

Accounting Shrink

‒

How is your inventory valued?

‒

How is cost of goods calculated?

‒

Effectiveness of physical inventory’s reconciliation?

‒

Has your organization trace transactions to the GL account?

‒

How many manual accounting processes are in place?

‒

Are all AP processes reconciled on a regular basis?

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

10

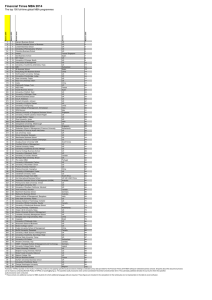

Summary Findings

False Overages

Markouts without Receipt Adj.

# of occurrences

# of occurrences

Receipt Adj. after AP match

# of occurrences

2000

14000

1500

12000

1500

10000

1000

8000

1000

6000

500

4000

500

2000

3077

3075

3074

3073

3072

3071

3070

3069

3066

3063

3078

3077

3075

3074

3073

3072

3071

3070

3069

3066

3063

3061

3077

3075

3074

3073

3072

3071

3070

3069

3066

3063

3061

3061

0

0

0

Key Influencers:

1. Changes in receiving , production and shipping policy at the cross docks due to new scanning technology

2. Increased volume of non-flow through freight not designed to support cross dock business rules

Split shipments (Batch v. flow)

Vendor consolidation

Packaging

Multi-cross dock deconsolidation

3. Increased volume of global imports managed by a broken global accounting process

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

11

Shrink Reporting

Shrink reporting lacks consistency in the method that it is collected, posted

and reported

How effective is your reporting related to:

‒

What accounting method do you use to report shrink

‒

Know shrink and waste

‒

Inventory adjustments

‒

PO, receipt, invoice & payments

‒

ASN exception reporting and receiving accuracy

‒

Vendor compliance

‒

Non-match reporting (RTV, PO Order Qty, Receipts, Wrong or missing PO)

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

12

Shrink Reporting

Improving Shrink reporting:

‒

SKU based information

‒

Tracking unit variance history vs. dollars

‒

Tracking unit history over larger periods

‒

Track and monitor inventory movement

‒

Track all product leaving the building POS, Backroom, trash compactor

‒

Monitor accuracy of price file

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

13

Inventory Shrink Roadmap

Discovery

PHYSICAL

Root Cause Analysis

Remediation

Steering committee

Executive Presentations

SYSTEMS

Working committee & project resources

Issue Identification

•

Framing the issue

Shrink workshop

Data Analysis

•

What gets better

Review current findings

Process& system reviews

•

Fundamentals

Identify Organizational Timeline

Root cause identification

Strategic roadmaps

Review key process, system & accounting

Quantify Identified Issues

changes

Observations & Recommendations

Outputs

PROCESSES

ACCOUNTING

High Level Systems Overview

High Level Data Flow

Map PI Process Flow

Develop preliminary list root causes

Develop high level project plan

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

Implementation roadmap

Activities

Milestones

Timelines

Resources

Cost

Impact on the bottom line

14

Discovery

Steering committee

‒

Working committee & project resources

Shrink workshop

‒

Review current findings

‒

Identify Organizational Timelines

‒

Review key process, system & accounting changes

Outputs

‒

High Level Systems Overview

‒

High Level Data Flow

‒

Map PI Process Flow

‒

Develop preliminary list root causes

‒

Develop high level project plan

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

15

Discovery

Review and document key processes, systems, accounting and reporting to

assist with the identification of gaps and to provide observations and

recommendations

‒

Set up cross functional meetings to discuss key business processes

‒

Document current state process flows, systems, accounting

‒

Review procure to pay processes, systems, and accounting

‒

Root cause analysis

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

16

Process, System and Accounting Maps

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

17

Example Deliverables – Detailed Process Mapping

Inventory Functional Area: Master Data; Index of Activities

N1

Merchant reviews Item

information

N8

Decline

Item

Request?

No

Yes

Re-assign

to Another

Merchant?

No

Merchant selects

another Merchant and

submits the request

Yes

Vendor

Portal

Vendor

Portal

Yes

No

N9

Merchant adds other

relevant information

including retail prices

and hierarchy

System routes item

request back to the

Vendor.

Yes

System routes

item

request to the

selected

Merchant.

A

Vendor

Portal

Approved

by

Merchant?

Merchandising

Vendor Portal routes

item request back to

the Merchant

A

System routes item

request to Item

Control based on the

Dept of the item

B

Standard Item Cost

Change by OD (Upload)

(pg. 7 of 10)

Vendor

Portal

No

Merchant selects a

DMM and submits the

request

Vendor

Portal

New Standard Item by OD

(Upload)

(pg. 6 of 10)

C.1.1.

1.2

C.1.1.

1.1

Vendor

Portal

A

New Standard Item by OD

(Manual)

(pg. 3-4 of 10)

Standard Item Cost

Change by OD (Manual)

(pg. 5 of 10)

Vendor updates item

information and

submits the request

Vendor

Portal

Receipt/Sales

(pg. 2 of 2)

System routes item

request to the selected

Merchant for approval.

C.1.1.

1.3

Vendor

Portal

Vendor inputs item

information including

cost, selects a

Merchant, and submits

the request

End

Standard Item Cost

Change by Vendor

(pg. 2 of 10)

N7

Start

Vendor

Portal

PG1.1

.1.1

WAC Update

(pg. 1 of 2)

Vendor

Portal

N2

Inventory Functional Area: Master Data; Process: 1.1.1 Item Master Maintenance – New Standard Item by Vendor (Page 1 of 10)

Vendor

Portal

Activities

New Standard Item

by Vendor

(pg. 1 of 10)

1.1.2 Weighted

Average Costing

Vendor

Portal

1.1.1 Item Master

Maintenance

Vendor

Process Flows

System routes item

request to the selected

DMM.

Delete Item

Request?

No

N3

Vendor

Portal

DMM reviews item

information

Vendor

Portal

System routes item

request back to the

Merchant

RMS

N8

Wholesaler Items

(pg. 8-9 of 10)

System updates its

internal item tables

Approved

by DMM?

C.1.1.

1.5

Yes

item management systems.

• N2 – A Standard SKU is defined as a SKU that can be sold across various channels and flows. Virtual and

Consignment SKU’s are created through the Standard SKU process. However, the SKU must be linked to a

virtual supplier or consignment vendor respectively. A Proprietary SKU is defined as a customer(s) specific

item outside of base assortment. Proprietary Items are created via the Quick Item Entry method in the

Standard SKU process.

• N3 – A Wholesaler SKU is defined as a SKU that is sourced from a wholesaler.

• N4 – Non-code SKU’s refer to product outside the normal assortment. Non-code items are normally bought

on a one-time basis for a contract customer.

Vendor

Portal

Item Control

reviews

item information

Approved

by Item

Control?

No

C.1.1.

1.4

Observations

• PG1.1.1.1 – Inaccurate item data input can have downstream effects that cause rework in EDI transmissions.

• PG1.1.1.2 – Inaccurate item data input can have downstream effects that create the potential for inaccurate

recording of inventory received.

A

N10

Yes

Hourly batch job runs

that pushes RMS item

table data into the

DB2

DB2

• N1 – Item Master Maintenance is the process to create, modify, or delete items/SKU’s within the various

N8

B

RMSHRLY

Batch Job

Process Description

Item Control Group

N4

Non-Code Items

(pg. 10 of 10)

Item tables updated

with DB2 item table

data

End

Process Controls & Observations

Process Description

• N7 – The Vendor Portal application is used to create new items or make cost changes by vendors, merchants, • C.1.1.1.1 – Merchant reconciles the item cost to the negotiated item cost. Merchant then approves or rejects

and the Item Control group.

• N8 – Approvals/rejections are captured in the Vendor Portal workflow.

• N9 – Merchants are responsible for determining the retail price of their items. Margin requirements vary based

on the department and item.

• N10 – RMS assigns each new item a unique SKU id.

Last Modified: 05/29/08 10:31:49 PM

•

•

•

•

the item.

C.1.1.1.2 – If the retail pricing is below the cost or above the list price entered by the Vendor, an error

message will be generated that will not allow the user to proceed until the retail price is corrected.

C.1.1.1.3 – Vendor Portal captures who initiated the new item/cost change request.

C.1.1.1.4 - Item Control Group reviews the item information to ensure (1) the description meets Item

Control’s criteria, (2) the accuracy of the UPC for inner case quantity, and (3) the existence of sell

dimensions. Item Control Group then approves or rejects the item.

C.1.1.1.5 - DMM reviews the item information to ensure that the margin guidelines are being met based on

the product category and channel the item will be promoted in. DMM then approves or rejects the item.

Last Modified: 05/29/08 10:31:49 PM

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

18

Discovery

Review the accuracy of the current retail or cost method of accounting

‒

Assess the retail or cost method of accounting

‒

Test cost compliment calculation or definition of cost

‒

Provide a summary of recommendations related to key themes (Definition of cost,

inventory adjustments, cycle counting, master data management, etc)

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

19

Discovery

Complete a reporting impact analysis

‒ Document key current operational and financial reporting related to margin, shrink

and inventory adjustments

‒

Importance of establishing one source of truth for reporting

‒

Assess master data clean-up and maintenance

‒

Assess shrink and waste calculations

‒

Assess inventory adjustments, cost adjustments, and other top level adjustments

impacting margin, shrink and inventory adjustments

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

20

Systematically research, identify, and resolve Inventory Variances and

Shrink

Unexplained Shrink

$95 Million Trend (200x)

Issues

Resets

Theft

Drop Ships at Stores

Vendor Contracts

Over Production

Auto-distro’s

R-claims

Markdowns

Etc

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

Validate and

Categorize

Quantify

Bucket 1

Bucket 2

Component 1

Component 2

Bucket 3

Component 3

Component 4

Bucket 4

Bucket 5

21

Categorize

Based on our analysis the top ten contributors to shrink in 200X are:

‒

Reported Shrink (Thrown Away) - $26.9 Million

‒

Shoplifting – $19.3 Million

‒

Under Reported Thrown Away - $15.1 Million

‒

Cost Compliment Variance - $ 9.2 Million

‒

Unknown – $4.9 Million

‒

Under Reporting (Thrown Away Weight Estimate Error) – $4.9 Million

‒

DC Pick Errors – $4.6 Million

‒

Cost Changes - $3.4 Million

‒

Retail Price Changes - $2.6 Million

‒

R-Claim – $2.3 Million

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

22

Categorize

Period covering May 1, 20xx – April 28, 20xx

$24M

$86M

Misaligned business rules across operations and general ledger processes

Markouts without receipt adjustments

Receipt adjustments after AP match

Lack of controls with global accounting process relative to changes to purchase orders and

receipt

$56M

$11M

$6M

Systems deficiencies with PO and ASN information

POM not updating GSS quantities

Duplication of ASN quantities

-Known Loss

Flexible receiving policies

$45M

Ability to receive shipments against any purchase order

-Shrink Reserve

Ability to change purchase orders once they have transacted with accounting

Assumed receipt information posting to the general ledger without verification at the cross

docks

2006-07

Preliminary

Inventory

Shrink

Results incl.

known loss

2006-07

ReserveInventory

Shrink plus

known loss

Final

Inventory

Adjustments

Reclassified

(balance

sheet items)

as Inventory

Inaccuracy at

the Cross

Docks

Inaccurate information provided by third party

K&N providing inaccurate ASN information

Final 20xx-xx

Inventory Shrink

($62M)

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

23

Remediation

Selling shrink projects to your executive suite

Developing Executive presentations

–

Frame the Issue

–

Setting the Priorities

–

Business Case Development

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

24

Frame the Issue - Example

Focus Areas

Business

Value

Difficulty

Estimated

Savings/Benefit

1) Improve reported shrink tracking and management reports

High

Med

$29-$36 Million

2) Distribution operational and financial reporting changes

High

Low

$8-$11 Million

3) Improve the preciseness of inventory valuation

High

High

$10-$14 Million

4) Master data clean-up and maintance

High

Low

$3-$5 Million

5) Store Detail receive all DSD shipments

Med

Low

$1-$2 Million

6) Theft Reduction

Med

Low

$2-$4 Million

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

25

Setting The Priorities

Realizing sustainable shrink improvement hinges upon setting clear priorities which consider

business value and level of difficulty.

High

Focus Areas

Gems

1

Difficult

but

Rewarding

Business

Value

2

3

1) Improve Shrink Tracking

2) Distribution Operations

3) Inventory Valuation

5

4

6

Back Burner

Quick Wins

4) Master Data

5) Detail Receiving

Low

6) Theft Reduction

Low

Difficulty

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

High

26

1 – Improve Reported Shrink Tracking

Observations

Shrink reporting should be standardized using cost or retail and should include all product removed from the store using a single

process. Shrink allowances & R-claim should be systematically tracked by vendor and included in management reports. Stores

should be rewarded for accuracy of shrink reporting and improvement, not based on a rate.

Recommended Actions

Assign a cross functional team with representatives from stores, distribution, buyers and finance to standardize, simplify and

develop the business requirements including:

Enable the stores using the handheld's to track the root cause and amount of reported shrink including:

–

Damaged, code dates, resets, production, force outs, and excess inventory

–

Scan all items removed from the store (ensure all item have UPC/PLU’s)

–

Track items used for production and include in cost of goods sold rather than shrink

The RMS system should direct the stores related to disposition of the product and record the shrink into the correct bucket

automatically

Use bar codes on each r-claim box for improved reconciliation

Establish guidelines for tracking other key information to assist in developing new reporting related to on-going diagnostic and trend

information including:

–

Late cost changes, Production tracking, RMS flag accuracy, R-claim variance reporting

Business

Value

H

Difficulty

M

Timescale

M

Assign IT resources to scope, develop detailed design and cost estimates to support business requirements

Business Value

Reduce current reported shrink from $49 Million to $13-$20 Million

Measure and understand the root causes of reported shrink

Costs

M

Monitor the appropriateness of shrink allowances

Improved R-Claim Reporting

Resources

M

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

27

Contact Information

Al Voels

Retail Practice Leader

KPMG Canada

Telephone: (206) 979-7654

Email: arvoels@kpmg.ca

© 2012 KPMG LLP, a Canadian limited liability partnership and a member firm of the KPMG network of independent member firms

affiliated with KPMG International Cooperative (“KPMG International”), a Swiss entity. All rights reserved.

28

© 2012 KPMG LLP, a Canadian limited liability

partnership and a member firm of the KPMG network of

independent member firms affiliated with KPMG

International Cooperative (“KPMG International”), a

Swiss entity. All rights reserved.