Freeport Site XA Strategy Update Centaurus Options - UNO-EF

advertisement

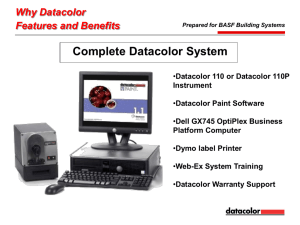

An Organized Approach to Energy Management SSCET, Sep 19, 2014 Tom Theising, C.E.M., C.D.S.M. (979) 709-6389 thomas.theising@basf.com 1 Overview BASF Corporation BASF Energy Management Industry Recognition Organization of Service Offerings BASF worldwide • The world’s leading chemical company • 380 production facilities including six Verbund sites • Employees: 117,000 BASF North America BASF Corporation (U.S.), BASF Canada, BASF Mexicana BASF North America • Agriculture 2012 sales Employees Production sites R&D sites $18.5 billion 16,665 99 27 Key customer industries • Automotive • Chemicals • Coatings • Construction • Health & Beauty • Packaging 5 Global Environmental Footprint Goals Cost /Risk Reduction Goal 2020 Status 2013 Reduce emissions from chemical operations Greenhouse gases (per metric ton of sales product) Energy Efficiency Improve specific energy efficiency of production processes - 40 % - 34.6 % + 35% + 26.2% BASF North America Annual Target • Improve energy efficiency by 2% (in ton/mmbtu) to further reduce greenhouse gas emissions Path Forward • Actively tracking project schedules and offering technical support/services • Developing new projects – “filling the pipeline” • Efficiency Best Practice sharing with smaller sites through Net-Meetings • Energy efficiency initiative for buildings & admin./warehouse sites American Chemistry Council Annual Energy Awards 1996 Energy Survey Program - Division and Site 1997 Energy Cost Reduction Program - HQ/Research 2010 Geismar EO Plant MPC Improvements 1998 Utilities Expansion Project - Cogen, Waste Fuels 2010 Geismar Polyol Plant Steam Reduction 1999 Corporate Energy Management Program 2010 Greenville Energy Optimization Initiative 1999 Corporate Motor Management Guideline 2011 Corporate Energy Management Process (EM) 2000 Geismar Cogeneration – AOG Fuel Utilization 2011 Geismar EO Vent Gas Scrubber 2001 Freeport Cogeneration Project 2011 Geismar MDI Steam Pressure Optimization 2002 Portsmouth Site Energy Team 2011 Jackson Flash Dryer 2003 Freeport ISBL Energy Audits 2011 McIntosh Production Schedule Optimization 2004 Energy management Group (Exceptional Merit) 2011 Pt. Arthur LP Fuel System Optimization 2004 Geismar Flare Best Practice 2012 Corporate Energy Management Process (EM) 2005 Site Energy Audits 2012 Geismar TDI Plant Steam Optimization 2006 Multi-Site Energy Reduction Through Teamwork 2012 Kankakee Site Wide Energy Conservation 2007 Energy Efficiency Improvements for Acquisitions 2012 Peekskill Instrument and Control Upgrade 2008 Energy Efficiency Improvement Goal (EM) 2013 Corporate Energy Management Process (EM) 2008 Port Arthur: Improved Hydrogen Utilization 2013 Manati Nitrogen Optimization 2009 Freeport Steam Optimization (EM) 2013 Pasadena Soy Flare Optimization 2009 Compressed Air Optimization (EM) 2013 Cincinnati Building 53 HVAC Optimization 2010 Energy Efficiency Program (EM) 2013 Freeport Anone II Advanced Process Control 2010 Corporate Energy Efficiency Improvement Goal Continuous Improvement Optimization Procurement Strategic Planning Management Commitment Assess Performance & Set Goals What is your roadmap to continuous improvement? Where do we conduct our next deep dive? Re-Assess Where are the largest opportunities? What has been achieved so far? Global/Regional Targets Create Action Plan Recognize Achievements Best Practices, Workshops Implement Action Plan Evaluate Progress KPI’s 8 Energy Optimization Offerings (toolbox) Reduce Variable Costs: • Focused Energy Analysis, by Utility Technology • • • • • • • • • • • Steam Refrigeration System Assessments (Trane) Compressed Air and Nitrogen System Assessments (Ingersoll Rand) Lighting (General Electric) Cooling Tower Assessments Energy Efficiency Best Practices (Handbook) Boiler MACT Evaluation (Steam System Assessment) Best Rates Analysis Energy Efficiency Evaluation (KPI Screening) Utility Invoice Auditing Water & Waste Water System Evaluations Energy Optimization Offerings (toolbox) Reduce Fixed Costs • Energy Maintenance Best Practices • • • • • Steam Trap Management Leak Repair Motor Management Lighting Technologies Insulation Best Practices Sustainability • Water Reduction • • • Global Targets Drought Prone Areas Responsible Care • • Reporting Audit Preparation Energy Optimization Offerings (toolbox) Reliability • Equipment Reliability • External Power Reliability Study • Internal Utility Reliability Check Organic Growth • Utility Strategy Development • Energy Concept • Calculation Prices • Location Selection • Cogen project development (gas turbine, steam turbine)