Mobile abattoirs: the BC experience

advertisement

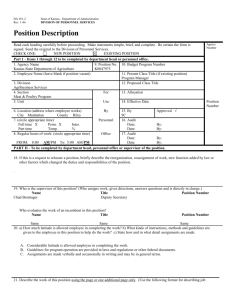

Mobile abattoirs: the BC experience 2005-2012 For Sustain Ontario mobile abattoirs webinar 30 October 2012 Presenter: Kathleen Gibson Former Manager of Meat Programs for the BC Food Processors Association Regulatory context • Pre 2004: limited meat inspection areas • 2004 Meat Inspection Regulation under Food Safety Act: licences, facility upgrades required for all slaughter for meat for human food • 2005-12: programs in place to assist with licensing and related costs • 2010: addition of D and E licences • 2011-present: prep for provincial inspection after 2013 BC’s graduated licensing system Industry impact • • • • • • Pre 2004, 300+ operations? A/B only option 2004: 11 A/B 2012: 59 A/B (43 A, 16 B) and 69 D/E Significant cost to build/upgrade A/B (< $1M) Mobiles may only be A or B Still concern in some areas about facility requirements for A/B, or lack of E • Still uncertainty about inspection post 2013 BC’s poultry mobiles 1/2 Passmore Pluckers, Slocan North Okanagan Poultry Processors, Armstrong Salt Spring Island facility Okanagan Poultry Processing, Kelowna BC’s poultry mobiles 2/2 BC status Oct 2012: 8 licensed mobile units - 6 active, 1 stationary, 1 inactive Cariboo-Central Interior Poultry Producers Association unit at docking station 1, Quesnel Red meat mobiles BC status Oct 2012: 1 licensed mobile unit (inactive); 1 nearly licensed; 3 under construction LEFT: BC’s Gate to Plate unit 1, Fort St. John ABOVE: Island Grown Farmers’ Co-op unit 1, Washington State BC’s mobiles: lessons learned • Not simple as hoped e.g. “move unit not animal” o Licence is for unit + approved docking station o Each DS has to address potable water, waste, chilling, other issues (non-trivial!) o Two types docking station: community or individual farm • Mobiles generally less cost-effective per carcass than fixed units: o o o o o o o Trailerable models cheaper to manufacture and operate than 53’ reefer type units Seem to work if start out debt free Volume is restricted Time and cost for setup including ice-making Down time when unit moving from site to site Crew time and travel costs; or train more crews Biosecurity of unit is a major consideration for farm-based docking stations • Operational logistics issues: o o o o o Road access limits size; cramped quarters slow the process Work flow is a key planning issue Difficult to chill on site Where to store carcasses if not on site? Red meat especially Scheduling: everyone wants service at same times, challenge coordinating with inspectors BC’s mobiles verdict so far? 1. 2. 3. 4. 5. 6. 7. 8. 6 active mobile poultry units; 0 active red meat units Business case needs total cost accounting Manoeuverability vs. workflow limitations Mobilization has to be well thought out, and limited (it’s still cheaper to move animals short distances) Invest in producer-processor relationships, build trust through education, celebrate successes Emphasize pre-planning from birth to death of animals Provide online support for scheduling, education etc. Ask advice from/network with operators of active units For further information: • Abattoir licensing and inspection in BC: www.health.gov.bc.ca/protect/meat-regulation/ • BC mobiles business case spreadsheets, Salt Spring Island multi-use project: Murray Coates, m.coates@shaw.ca • North Okanagan Poultry Processors group and unit: Andrea Gunner, gunnera@telus.net