Hydraulic Fracturing

advertisement

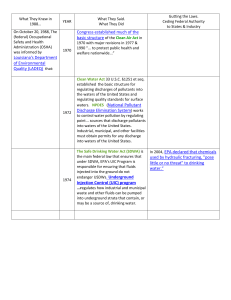

Overview of Hydraulic Fracturing May 31,2013 USDOL/OSHA Ronald Williams – Compliance Assistance Specialist 3300 Vickery Rd. North Syracuse, NY 13212 315-451-0808 ext. 3002 Art Dube, Area Director Gordon DeLeys, CAS Buffalo Area Office 130 S. Elmwood Avenue, Suite 500 Buffalo, NY 14202 (716) 551-3053 x244 Chris Adams, Area Director Ron Williams, CAS Syracuse Area OSHA Office 3300 Vickery Road N. Syracuse, NY 13212 (315) 451-0808 x3002 Kim Castillon, Area Director Albany Area Office 401 New Karner Road, Suite 300 Albany, NY 12205 (518) 464-4338 Diana Cortez, Area Director Tom McCarthy, CAS Tarrytown Area Office 660 White Plains Road Tarrytown, NY 10591 (914) 524-7510 Tony Ciuffo, Area Director Long Island Area Office 1400 Old Country Road Suite 208 Westbury, NY 11590 (516) 334-3344 Kay Gee, Area Director John Frowd, CAS Manhattan Area Office 201 Varick Street, Room 908 New York, NY 10014 (212) 620-3200 • Introduction –What is hydraulic fracturing? –OSHA’s perspective –OSHA’s actions • Safety concerns • Health concerns and hydraulic fracturing fluid Shale Plays Hydraulic Fracturing Picture from Plan to Study the Potential Impacts of Hydraulic Fracturing on Drinking Water Resources, EPA 2011 Top Side Water Storage Tanks Chemical unit Sand Trailer Frac Control Van Blender Pumper Units Well head Hydraulic Fracturing is one in many upstream operations in an industry with a high fatality rate (2006-2010) Rate per 100,000 Workers Source: Private Sector Fatality Rates- Bureau of Labor Statistics Census of Fatal Occupational injuries (CFOI) O&G Fatality Rates - OSHA calculated using CFOI fatality counts and employment data from the BLS Quarterly Census of employment and Wages. Possible risks for consideration Are HF Workers at Greater Risk of Occupational Illness? Are HF Workers at Greater Risk of Occupational Injury? • Increased Time On Site – Increased Potential for Injury – Longer hours/fatigue? • Materials Transport – Increased Risk of MVAs • • • • Silica Diesel Chemicals Increased Time On Site – Increased Exposure to Chemicals – Increased Exposure to Heat OSHA is including HF into existing O&G activities to assess any new risks • Local Emphasis Programs on Oil and Gas – HF is part of the Oil and Gas field – HF inspections are occurring • Better understand hazards – gathering inspection information – working with partners (e.g. NIOSH) Hydraulic Fracturing Safety Hazards Hydraulic Fracturing Safety Hazards • Well Location/Pad Drilling • High Pressure • Loud Equipment • Silica Exposure • Permit-Required Confined Space • Walking/Working Surfaces • Fall Protection • Control of Hazardous Energy (LOTO) • Personal Protective Equipment (PPE) • Pre-Job Meeting • Flammable Gases and Vapors Well Location Water Storage Tanks Chemical unit Sand Trailer Frac Control Van Blender Pumper Units Well head Multiple or Pad Location Wireline Perforation truck Manifold Trailer Truck mounted crane Wireline Logging Unit High Pressure Hazards (cont’d) High Pressure Hazards (cont’d) Chokers Chokers Loud Equipment Blender Manifold Trailer Triplex Pumper Quintuplex Pumper Proppant Use Silica Exposure (discussed later) Sand Conveyor Field Sand Storage Trailer (aka Sand Hog) Sand Conveyor Permit-Required Confined Space (PRCS) Portable Frac Tank Cellar Waste Water Pit Other Examples of PRCS Sand Dump Truck Field Sand Storage Trailer Chemical Unit Acid transport truck Walking/Working Surfaces Fall Protection Control of Hazardous Energy (LOTO) Personal Protective Equipment (PPE) PPE (cont’d) Pre-Job Meeting Flammable Gases and Vapors Hydraulic Fracturing Health Hazards Hydraulic Fracturing Health Hazards • • • • Background Water Base Fluids Silica • Chemicals • Potential Hazards & Solutions Background • Chemicals typically make up just 0.5 and 2.0% of the total volume of the fracturing fluid. When millions of gallons of water are being used, however, the amount of chemicals per fracking operation is very large. For example, a four million gallon fracturing operation would use from 80 to 330 tons of chemicals. • Fracture fluids may be based on either acid, gel, water, or oil – Most fracturing work is water based Background (cont’d) • Toxic chemicals exist in frack fluids • Top health effects include: skin, eye, respiratory, & gastrointestinal effects, and brain and nervous system effects • “NORM” in relatively small quantities of radium, radon and uranium NORM: Naturally Occurring Radioactive Material Background (cont’d) • Myth: Flow back and Produced Water pose a real risk to employees • Fact: The chemicals used in fracking pose the highest risk when in bulk, concentrated form • There is a X to X ratio of water to chemicals • Health – Proper PPE – Portable Eyewash/Shower – Training Water • Water is the driving fluid used in the hydraulic fracturing process • Depending upon the characteristics of the well and the rock being fractured a few million gallons of water can be required to complete a hydraulic fracturing job Water and Sand: 99.51% • This water can be fresh water or recycled water • Sand is the proppant • Silicosis • Alternatives are often available (e.g. ceramics) Silica Exposures OSHA/NIOSH Hazard Alert • Summarizes some preliminary data on silica exposure • Critical for raising awareness about this hazard – Exposure data and operations where over exposures can occur • 47% samples collected exceeded OSHA’s PEL • 79% samples collected exceeded NIOSH REL – Control measures (engineering and respirators) – Assistance/Services/Tools Controls for Silica Exposure • Use local exhaust ventilation • Enclose points where dust is released • Reduce drop on sand transfers • Replace transfer belts with screws • Use water for dust control • Limit worker exposure, rotations NIOSH designed control Many Types of Fluids • • • • • • • Water Friction reducers Corrosion inhibitors Clay stabilizers Acids Gelling agents Oil The following table shows an example of what hydraulic fracturing fluid contains: Note that this is an example of what may be used in hydraulic fracturing operations. Constituent Examples Water Purpose Volume % Gallons Delivery 90 2,700,000 Proppant Sand Keep fracture open 9.51 285,300 Acid Hydrochloric Dissolves minerals, opens fracture 0.123 3.690 Friction Reducer Polyacrylamide, mineral oil Reduce friction 0.088 between fluid and pipe 2,640 Surfactant Isopropanol Increase fluid viscosity 0.085 2,550 Make brine 0.06 1,800 Suspend proppant in fluid 0.056 1,680 Potassium Chloride Gelling Agent Guar gum The following table shows an example of what hydraulic fracturing fluid contains: Note that this is an example of what may be used in hydraulic fracturing operations. Constituent Examples Scale inhibitor Purpose Volume % Gallons Ethylene glycol Prevent scale deposits in fluid 0.043 1,290 pH buffer Carbonate Protect pH sensitive chemicals 0.011 330 Prerservative Ammonium persulfate Delay gel breakdown 0.01 300 Crosslinker Borate salts Maintain viscosity 0.007 with temperature 210 Iron Control Citric Acid Prevent metal 0.004 oxide precipitates 120 Corrosion Inhibitor n,n-dimethyl formamide Prevent corrosion 0.002 60 Biocide Glutaraldehyde Inhibit bacterial growth 0.001 30 Potential Health Hazards • Ignition and respiratory hazards • Potential ignition of flammable or combustible carrier or base fluids • Chemical hazards (such as, silica, toxics, asphyxiants) • Radiation associated with radioactive tracer materials Possible Solutions • Wear proper respirators • Provide bonding and grounding for blending, pumping, and sand transfer equipment • Use hose covers/shielding for transfer or suction lines containing flammable liquids • Prevent contamination and exercise proper personal hygiene Summary • Steps to Safety and Health • Site Preparation • Traditional Safety Hazards traditionally found in oil and gas are present • Management of Fluids and Proppants • Controls, Safe Work Practices and PPE • HazCom • Monitoring and Measurement Equipment • Emergency Response Procedures Industry Reference and OSHA Info Most widely used industry consensus standards include: • American Petroleum Institute (API) • RP 54 Oil and Gas Well Drilling and Servicing Operations • International Association of Drilling Contractors (IADC) • Safety on the Rig • Accident Prevention Reference Guide • American Society for Testing and Materials (ASTM) • 2733 Standard Specification for FR rainwear • National Fire Protection Association (NFPA) • 2113 Selection, Care, Use, and Maintenance of FR garments OSHA Website • Oil and Gas Well Drilling and Servicing eTool • Stimulation • Wireline Operations • Well Logging • Perforating Ronald Williams (315) 451-0808 ext. 3002 williams.ronald@dol.gov www.osha.gov