Kraftpak - Warren Board

advertisement

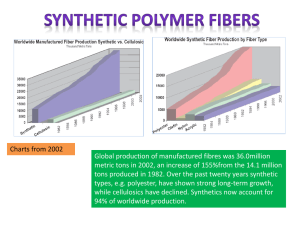

Overview in brief Composition Grammage to Stiffness Appearance Production Supply Chain Sustainability Typical Markets Printing Cutting and scoring in brief Manufactured by KAPSTONE in their Charleston Mill, South Carolina High performance, low density, 2 ply folding Cartonboard Excellent Stiffness to grammage ratio Natural uncoated appearance, helping to convey an Earthy, Organic and Sustainable message to consumers Manufactured using 100% virgin fibre Hardwood and Softwood fibre used Manufactured in nine basis weights 225gms (330 micron) to 410gms (762 micron) Fibres Strategic, controlled mix of hardwood and softwood Hardwood 1.5mm Pine 3-5mm Composition Kraftpak is internally sized – Low Cobb Values Short Hardwood Fibres One minute Cobb, 30 g/m2 Long pine fibers One minute Cobb, 30 g/m2 Uncoated, pure, clean kraft fibers. Certified compostable (EN 13432) Grammage to Stiffness Ratio Kraftpak boasts a superior grammage to stiffness ratio than other GC/GD cartonboard grades 25% reduction in packaging weight can typically be achieved when switching to Kraftpak Resulting in more Cartons per tonne Outstanding moisture resistance and wet durability make Kraftpak the perfect choice for many challenging packaging applications Natural Appearance A natural, non-bleached, brown appearance. Kraftpak’s fibres are uniform and consistent, but not bleached, stained or coated Natural variation in shade is negligible as per C Lab chart Typical colour ranges over one year L a b Mean 59.746 6.869 17.545 StDev .384 .382 .609 Min 58.87 5.77 15.810 Max 60.51 7.71 18.890 Shade-Colour Space Production - KAPSTONE® Kraftpak manufactured twice every 5 weeks 7-8 week delivery from receipt of order Mill located at Quay – No inland haulage delays! Thirty year history of excellent performance and consistent customer supply Committed to the continued growth of Kraftpak to meet increasing demand in the marketplace Increases in Kraftpak supply will be achieved by reducing Kraft liner supply Supply Chain Production schedule made available to customers every week Reel stock held against a firm customer order Warren Board, Leicester hold stock sheets Mill orders sheeted in the UK and delivered within 7 days of reels arriving Security of Supply Charleston mill boasts long history of consistent reliability Demonstrated by their 50,000mt/pa relationship with a major U.S. retail brand of beverage carriers for 20 years. Sustainability High yield pulping and low density papermaking process COGEN power is used, 72% of mill fuel from renewable sources. All residues from waste treatment are used as biofuels Cradle-to-gate life cycle assessment conducted by PE International finished in 2011. Net result of Biogenic carbon storage, from uptake of CO2 in growing forest and emission from operations, results in a net carbon storage available at the Mill gate Sustainability Kraftpak Carbon Footprint Cradle To Gate GHG Impact 1000 784 Kg CO2 Equivalent Per Ton 500 0 372 Fibre Carbon Storage 187 Material Overall from Fibre to Gate Energy Charleston Mill -500 -1000 -1500 -1497 -2000 Overall Kraftpak carbon footprint as it leaves the mill gate: Net carbon storage after all energy, materials usage and emissions -149 Responsible Packaging Kraftpak’s 100% renewable fibres are a valuable resource for Recyclers …and are 100% recyclable where facilities exist Should Kraftpak end up in landfill, Kraftpak is certified biodegradable and compostable (ISEGA, EN13432) – Typical Markets Food Hygiene Kraftpak meets ISEGA requirements for direct food contact Beverage bottle carriers and baskets Beverage can carriers Frozen meats and pies Carry out takeaway trays Bakery items Fast food drink carriers Frozen biscuits Novelty ice cream packaging High performance filter frames Kraftpak has proven, demonstrated success in all of the above environments Examples Wet Applications Examples Dry Applications Printing - Flexo Anilox rolls should have cell volume adequate for delivering inks and coatings to kraft board 200 lines/inch (80 lines/cm) are commonly used Printing is possible on softwood side, but frequent wash-ups to be expected Softer plates and cushions may be beneficial for improved surface contact Printing - Litho Will generally require more impression pressure than other carton grades Compressible blankets recommended for offset Impression cylinder pressure should also be adjusted as necessary to avoid mottle Ink film thickness of 0.5mls may be needed for adequate ink cover Gap setting of .002” to .004” below nominal is a good starting point Printing – Litho Ink tack levels in the 8-12 range (800rpm) are recommended UV curing can provide ability to print white base patterns as needed on a single pass Textured grippers may help with consistent sheet transfer On litho presses, it is strongly recommended to feed kraftpak sheets in the CD direction Cutting and Scoring Excellent Converting Efficiencies Cutting, Scoring, Folding, Gluing Resulting in... Fewer rejects Increased speeds Less downtime Increased handling rates Scoring High strength to weight promotes excellent performance in scoring and embossing Low density means Kraftpak is more compressible than other cartonboards Scorelines will need to be deeper to avoid springback Slightly higher impression pressure may be required to achieve adequate scorelines Cutting Cutting is similar to CUK, but significantly different to that of SBS and recycled grades Knives need to be sharp Fewer and smaller nicks are needed for perforation due to Kraftpak’s high fibre strength Cutting parameters should be chosen to overcome the strong, compressible nature of Kraftpak Scoring Parameters Recommended initial scoring parameters (grain and crossgrain) are below. Note, these are only initial guidelines. Rule Width 2pt rule for .013-.018 caliper Kraftpak 3pt rule for .020-.030 caliper Kraftpak Channel Width Twice board caliper plus the rule width Rule Penetration Target 0.006” penetration beyond top of channel