2008: Webcast - Annual results

advertisement

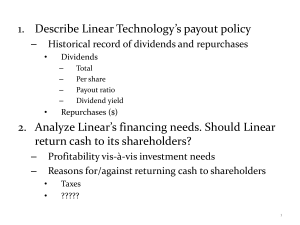

ArcelorMittal South Africa Limited Annual Financial Results for the 12 months ended 31 December 2007 Introducing New CEO and member of the Board Me. Nku Nyembezi-Heita 2 Introducing new President and member of the Board Luc Bonte 3 Market and Operations Rick Reato Introduction and Overview Earnings increase to R5.7bn Earnings per share of 1 288c up 21% Net cash flow of R2.9bn Domestic market retained momentum Demand essentially unchanged on 2006 Domestic sales constitute 76% of total sales Cost pressures continue Raw material cost increased by 14% Cost of steel sales increased 17% Operations BFD rebuild completed Liquid steel production down 10% Sales down 6% Earnings increase by 21% 5 Key Result Drivers 2007 vs 2006 HRC US$ export price +22% LCWR US$ export price +26% Total sales volume -6% Export sales volume -22% Domestic sales volume +1% HRC Rand cash cost per tonne +18% Billet Rand cash cost per tonne +16% Labour productivity -3% ZAR movement -4% Production volumes impacted on sales volumes 6 Global Environment – General Market Trends World economic growth in 2007 decreased marginally from 3.9% to 3.6% Chinese economy grew by 11% despite measures to cool it down World consumption and production of steel increased by 7.5% in 2007 Global steel industry consolidation still priority Input costs remain high & will continue to support prices Lower price volatility expected to continue Global steel consolidation supports a less volatile market environment 7 Global Environment - Chinese Market Trends China remained a net exporter of total steel products in 2007 China accounted for 37% of world steel production and 35% of consumption Export taxes increased ktonnes 45,000 20,000 -5,000 -30,000 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 Source : TEX Report Net China expected to retain its status as a net exporter Import Export 8 Global Environment – Input Cost Trends Iron ore price expected to increase substantially China iron ore spot @ premium of US$40/t Coking Coal cost pressure expected in 2008 due to scarcity worldwide Coking coal spot prices have increase by 65% Sharp increase in scrap prices in early 2008 Scrap prices increased by 30% during 2007 Reduction in supply from traditional markets due to local consumption Port delays & changing trade patterns lead to rising freight rates Freight rates almost doubled during 2007 Prices of base metals and alloys increased substantially Tin (+66%); Nickel (+55%); Ferro Alloys (+60%); Zinc stable after +146% in 2006 Raw material prices exert pressure on steel prices 9 Global Environment – Benchmark Prices 400 Spot coal prices Based to 100 300 200 100 0 2003 2004 2005 2006 2007 Coking Coal Global input costs continue to increase 2008 Iron Ore Scrap (Tex) 10 Global Environment - Export Prices Achieved 800 Export prices (c&f) US$/t 700 600 500 400 300 200 100 HRC Steel prices established new trading range Low carbon wire rod 11 Domestic Environment – Shipments 6,000,000 5,000,000 4,000,000 3,000,000 2,000,000 1,000,000 0 69 73 77 81 85 89 93 97 01 Long (t) 05 Flat (t) Source : SAISI Long steel local despatches again achieved a record level 12 Domestic Environment – Inventory Levels 1,500,000 20 16 1,000,000 12 8 500,000 4 0 0 69 73 Stocks (t) 77 81 85 89 93 97 01 05 Week’s despatches Source : SAISI Industry inventory levels below recent averages 13 Domestic Environment – Imports 1,200,000 24% 20% 800,000 16% 12% 400,000 8% 4% 0 0% 69 73 77 81 85 89 93 Imports (t) 97 01 05 % of consumption Source : SAISI Imports slightly down from 2006 14 Key Performance Indicators 2006 2007 Employees per million tonnes produced 1 385 1 429 Revenue per head (R000) 2 594 3 220 HRC cash cost - R/t - US$/t 2 150 318 2 538 360 Billet cash cost - R/t - US$/t 1 993 295 2 310 327 Percentage value-add exports - flat - long 96% 94% 97% 100% Productivity influenced by lower volume 15 Liquid Steel Production 8,000 7033 7,000 7261 7055 6375 ktonnes 6,000 5,000 4855 5067 4863 4231 4,000 3,000 2178 2194 2192 2144 2,000 1,000 0 Flat Products Long Products 2004 Total 2005 Blast furnace rebuild and Corex reduced output volumes 2006 2007 16 Liquid Steel Production ktonne 2006 liquid steel output 7 055 Recoupment of 2006 losses +323 Vanderbijlpark - BFD Rebuild -813 Vanderbijlpark - BFD Cold hearth conditions -177 Saldanha - Corex condition -49 Newcastle - Furnace condition -57 Efficiency improvements +93 2007 liquid steel output 6 375 BFD biggest impact on output volumes 17 Operational developments Blast Furnace D Market Coke production at battery N2 at Newcastle Works Galvanizing line 5 achieved full capacity Colour coating line achieved record output EAF at Vereeniging produced record volume Various records at all rolling mills at Newcastle Blast Furnace D overshadowed production 18 Shipment Volumes 6 223 6 230 6,000 ktonnes 5,000 4 329 2344 4 283 4,000 1601 3,000 1881 4 268 1299 1,000 2728 2402 1794 2745 5 829 1408 3 928 1042 2,000 2969 6 194 2886 1 894 1 947 743 864 1151 1083 2004 2005 1 926 1 901 495 366 1431 1535 2006 2007 3879 4400 4421 2006 2007 3485 0 2004 2005 2006 Flat Products 2007 2004 2005 Total Long Products Domestic Substantial shift to meet local demand on long products Export 19 Geographic Shipments South Africa 76% Rest of Africa 12% Total Africa 88% Americas 0% Asia 11% Europe 1% 0% 10% 20% 30% 40% 50% 60% 2004 Maintain Africa focus 70% 2005 80% 2006 90% 100% 2007 20 Investment Programme Rm 2007 Major projects completed (and ongoing) in 2007 Vanderbijlpark Works - Blast furnace “D” rebuild completed - New direct reduction kilns 5 & 6 on track (2008) Saldanha Works - Corex/Midrex reline preparation - Ore screen & stockhouse upgrade Newcastle Works - Evaporator crystalliser & RO plant upgrade - Blast Furnace “N5” Mini-reline (2008) Vereeniging Works - EAF Dust extraction (2008) - Crane replacement and gantry upgrade at Steelmaking (2008) Coke & Chemicals - Battery rebuild (Newcastle) Other (mainly Mozambique) Total Expenditure in 2007 Furnace refurbishment absorbed 30% of total cash flow expenditure 1 183 260 199 50 59 97 1 848 21 ArcelorMittal South Africa achieved 26 LTI free days (3.7m LTI free man hours) 1m LTI free hours achieved 7x at Vanderbijlpark Works 6x at Newcastle Works 1x at Vereeniging Works 1x at Saldanha Works Best ever safety performance by Newcastle Works Lost Time Injury Frequency Rate (LTIFR)* Safety Remains our Priority 7.0 6.0 5.0 4.0 3.0 2.0 2002 2003 2004 2005 ArcelorMittal South Africa 2006 2007 IISI *Includes contractors Best ever safety performance 22 Finance Kobus Verster Headline Earnings Rm 2006 Revenue 2007 25 350 29 333 6 082 7 703 Gains & losses on foreign exchange rates and financial instruments 301 -131 Financing cost 294 -101 369 -44 7 4 -2 022 -2 455 135 270 34 25 4 730 693 5 741 816 Operating profit - net interest income - imputed interest on non-current provisions Income from investments Tax Equity earnings* Net deficit on disposal or scrapping of assets* Headline earnings - in US$m *After tax Record earnings 24 Headline Earnings Trend 1,800 1586 1,600 1398 1,400 1582 1653 1532 1488 1439 1247 1623 1292 Rm 1,200 800 600 400 1056 988 1,000 1528 869 661 703 656 672 599 353 200 0 1Q 2Q 3Q 4Q 1Q 2Q 3Q 4Q 1Q 2Q 3Q 4Q 1Q 2Q 3Q 4Q 1Q 2Q 3Q 4Q 2003 2004 2005 Earnings remains within ‘new’ range 2006 2007 25 Operating Profit Rm 2006 2007 Flat products 3 644 4 338 Long products 2 111 2 661 Coke & Chemicals 184 727 Corporate & other 143 -23 6 082 7 703 Operating profit Long products and Coke & Chemicals continue to increase their contribution 26 Cash Flow Rm 2006 Cash profits from operations Working capital Capex Net interest/Investment income Investments Tax Dividends Net cash flow Capital reduction Net cash flow after capital reduction Net cash Cash flow remains robust 7 132 -1 033 -1 446 468 -1 660 -1 261 2 200 2 200 7 679 2007 9 021 -606 -1 848 476 -16 -2 209 -1 948 2 870 -6 352 -3 482 3 973 27 Financial Ratios 2006 2007 Operating margin 24% 26% EBITDA margin 28% 30% 1.4 1.5 Return on equity 22% 26% Net cash/equity 33% 19% Revenue / invested capital (times) Improvement in financial ratios 28 Share Performance 650 Period 2003 to 2007 Average Dividend Yield at 5.7% (excl cap red) - double the market 550 Average Price Earnings ratio of 7.2X - half the market 450 350 250 150 50 Arcelor Mittal South Africa Excellent medium to long term share performance ALSI Top 40 29 Dividend Dividend policy Distributing one third of headline earnings Dividend and cash declared Interim dividend of 233 cents per share - 3 September 2007 Final dividend of 196 cents per share - 17 March 2008 Total dividend of 429 cents covered 3 times by EPS of 1 288 cents Capital reduction of 1 425 cents - September & October 2007 Total cash distribution of 1 854 cents over past twelve months Cash yield at 13.6% 30 Other Developments Rick Reato Meeting local demand Channels for capturing strong local demand and strong international prices Production stability Divert exports N5 and Corex/Midrex relines Investing in additional capacity Electricity supply Focus on production stability 32 Investment Programme Rm 2008 - 2011 Relines 450 Maintain capability 2 000 Steel capacity increase 2 900 Downstream value adding projects 2 700 Environmental investments 1 000 Expenditure in 2005 1 608 Expenditure in 2006 1 446 Expenditure in 2007 1 848 Investment programme support expansion strategy 33 Major Investments up to 2011 Flat products DRI kilns (2008) Corex and Midrex reline (2008) New Colour Line (2009) New Galvanising line (2011) Power plant Ore screen and stockhouse upgrade (2009) Long products N5 reline (2008) Maputo mill (2008) New Bar/Section Mill (2011) New Blast Furnace “N6” (2011) New Billet Caster (2011) Crane and gantry upgrade (2008) 34 Major Investments up to 2011 Environmental Sinter clean gas EAF dust extraction at Vanderbijlpark Works EAF dust extraction at Vereeniging Works Calcium Carbide Desulphurisation at Newcastle Works Evaporator crystallizer 35 Ongoing developments Competition Tribunal SARS BAA dispute Iron ore supply Electricity supply BEE 36 Cost containment Production stability Increased throughput Purchasing power Efficiency improvements Cost Control 37 Outlook Rick Reato Outlook for Q1’08 Business environment Domestic demand expected to remain healthy Higher international prices expected Higher input prices will influence production costs Earnings Earnings to remain strong compared to Q4’07 Power supply and the exchange rate may have an influence Earnings expected to remain strong in Q1’08 39 ArcelorMittal South Africa Limited Annual Financial Results Thank you