What is Engineering Psychology?

advertisement

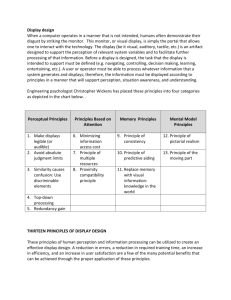

Psychology & Work Today Engineering Psychology Learning Objectives After reading this chapter, students should be able to: 1. Define ergonomics and describe its role and function in the workplace 2. Outline the history and scope of engineering psychology 3. Explain the relationship of displays, controls, and the human operator in a person-machine system 4. Describe the major considerations involved in the design of a workspace 5. Contrast the advantages and disadvantages of auditory and visual presentation of information 6. Define telematics and its importance to engineering psychology 7. Describe the use of human factors in everyday life, with examples 8. Understand and explain the factors that should be considered in the design of a computer work station What is Engineering Psychology? • The design of machines and equipment for human use, and the determination of the appropriate human behaviors for the efficient operation of the machines • Also called • Human factors • Human engineering • Ergonomics History and Scope of Engineering Psychology • Prior to 1940, engineers made machines without considering the human factor • The worker was adapted to the machine through time-and-motion studies • WW II weaponry was complex but did not perform up to expectations, thus giving rise to engineering psychology • Example: There was no consistency in design of aircraft controls. “On” position for some controls was up, for others, down – difficult to remember in a dog fight. Many pilots died as a result History and Scope of Engineering Psychology • Poor design resulted in many accidents • Three Mile Island in 1979 - poor design of controls • NTSB added engineering psychologists to its staff to study pilot error • Human factors research resulted in safer automobiles, including redesigns of headlights, brake lights, and tinted windows • Other areas of effort include license plate visibility, signage, cell phone use while driving, driver aggression, and mailbag design • Ergonomics has net gains of 1 to 12% over the costs of human factors interventions Engineering Psychology is a Hybrid • Members of the Human Factors and Ergonomics Society includes: • Psychologists • Engineers • Medicine • Sociology • Anthropology • Computer sciences • Other behavioral and physical sciences Time and Motion Study • An early attempt to redesign work tools and to reshape the way workers performed routine, repetitive jobs • F.W. Taylor (1898) performed first empirical demonstration of the relationship between work tools and worker efficiency • Introduced shovels of different sizes for handling different materials • 21 1/2 pounds was the most efficient load at a U.S. Steel company study • Saved the company $78,000 per year Time and Motion Study • Frank and Lillian Gilbreth (1911) were interested in the mechanics of job performance to eliminate unnecessary motion • Started with improving the efficiency of bricklaying • Increased rate of bricklaying from 120 to 350 bricks an hour by reducing motions from 18 to 5 • The basic unit of motion was the Therblig (Gilbreth spelled backwards) • Gilbreth’s had 12 children – their lives were depicted in the movie Cheaper by the Dozen • More info at http://gilbrethnetwork.tripod.com Guidelines for Increasing Efficiency of Manual Jobs • • • • Minimize reaching distance from worker Symmetrical movements of both hands Hands should never be idle Hands never do tasks that can be performed by other parts of body • Work materials held by a vice • Workbench height adjusted to prevent fatigue Person-Machine System • • • • • A system in which human and mechanical components operate together to accomplish a task Human operator receives input on machine status from the displays Such systems vary in the extent to which the human operator is actively and continuously involved Humans remain important components of automated manufacturing systems Automation makes the engineering psychologists job more demanding as monitoring machinery is more monotonous than actually operating it Allocating Functions Between The Operator & Machine • Engineers first carefully analyze each process in the functioning of the total system to determine its characteristics • Speed, accuracy and frequency with which it is performed • Stress under which occurs • They then make decisions regarding man - machine division of labor Machine Strengths • Detecting stimuli beyond human sensory capacities • Monitoring reliably for lengthy periods • Making large numbers of rapid, accurate calculations • Storing and retrieving vast amounts of information • Applying continuous and rapid physical force • Engaging in repetitive activities Machine Limitations • • • • Not very flexible Cannot learn from errors Cannot improvise When operators only monitor, disastrous results can happen • e.g., bored pilots or subway drivers • However, full automation is dangerous as systems can fail – no intervention available without human monitor Principles for Workspace Design • All materials should be placed in order in which they will be used so paths of movements will be continuous • Tools should be pre-positioned for use • All parts and tools should be within comfortable reach • Greater than about 28 inches causes unnecessary repositioning and consequent loss of efficiency and increased fatigue Other Design Considerations • Heights of all working surfaces should be adjustable • Hand tools should be designed for use without bending wrists • Hammers with angled handles work better • Properly designed tools affect productivity, satisfaction, and physical health • e.g., reduction of carpal tunnel syndrome Human Anthropometry • • A branch of engineering psychology concerned with measurements of the physical structure of the body, including • Height – standing and sitting • Shoulder breadth • Back height • Chest depth • Foot and hand length • Knee angle These measurements are applied to design of work areas to determine normal and maximum reaching distances, tool and desk height and arrangement, etc. Presenting Visual Information in Displays • Visual presentation is most appropriate when • • • • Message is long, difficult and abstract Environment is too noisy for auditory signals Auditory channels are overloaded Multiple kinds of information to be presented simultaneously Auditory Presentation of Information • Auditory presentation most effective when: • Information is short, simple, and straightforward • Message is urgent • Environment is too dark for visuals • The operator’s job requires moving to different locations Types of Visual Displays • Quantitative displays present a precise numerical value such as speed, altitude or temperature • An open window display is read with fewest errors, and the vertical display was misread one third of the time (See Fig. 13-5) • Digital display can be read faster with fewer errors, but cannot be used in all situations • e.g., if conditions are rapidly changing, or need to know direction of change Qualitative Displays • Displays that present a range rather than a precise numerical value • e.g., red area hot – green area normal – yellow area cold • Consistent patterning makes multiple displays easier to read • Used in aircraft cockpits • Unpatterned displays force operator to read each dial separately Check Reading Visual Displays • Simplest kind of visual display • Tells operator whether the system is: • On or off • Safe or unsafe • Normal or abnormal • Warning light most common • Twice as bright as background • Centered in field of vision • Flashing Auditory Displays • Auditory displays can be more compelling than visual because • Ears always open • Multi-directional • Visual often taxed to capacity • Problem with “nuisance alarms” • If alarms are too sensitive or occur too frequently, they are often ignored Guidelines For Controls • Control-body matching • Most rely on hands and feet • No one limb should be given too many tasks • Control-task compatibility • A control action should imitate the movements it produces • Turning steering wheel right makes right turn • When possible, combining controls that perform similar or related functions is more efficient Guidelines For Controls • Identification of controls • Controls should be clearly marked or coded • e.g., shape coding for touch recognition • Placement of controls • Consistency and uniformity is important • Consider cultural influences on preferences • Emergency controls in line of sight, clearly distinguishable and protected with a cover • Group related controls and displays according to function Human Factors in Everyday Life • Human factors no longer confined to tanks, airplanes and work areas • Telematics deals with wireless information technology such as GPS, Satellite radio, and builtin wireless phone for cars • Ergonomics examines cell phone use while driving to prevent accidents • Use of auditory signals to alert drivers they are too close to another car • Spatulas that reduce risk of carpal tunnel, sharpened ice cream scoops…. Computers • Poorly designed computers and work stations produce strain and discomfort • Eyestrain and blurred vision • Fatigue and pain • Comfort range for keyboard operation is an angle of 7-20 degrees with an elbow angle of 90 degrees • Optimal viewing distance of 15 to 30 inches • Optimal screen height is 33-42 inches • Mouse redesigned to reduce movements Key Terms • • • • • • • • • Auditory displays Check reading visual displays Engineering psychology Human anthropology Person-machine systems Qualitative visual displays Quantitative visual displays Shape coding Time-and-motion study