Work Permit Procedure

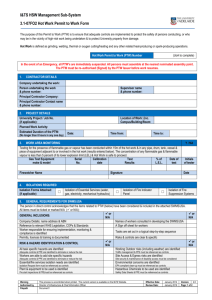

advertisement

Work Permit Procedure Objective This procedure shall ensure that work identified as potentially hazardous is controlled by a documented system, that personnel performing such work are instructed in writing and that personnel affected by work are safeguarded. Work Permit Procedure Background Information A Permit to Work system aims to ensure proper planning and that consideration is given to the risks of a particular job. The Permit to Work is a document which authorizes certain people to carry out specific work for a specific period of time at a specified place and which sets out the main precautions needed to complete the job with the minimum amount of risk. Work Permit Procedure Background Information The system is also a means of communication between key staff i.e. those who perform the work, those affected by the work and those coordinating the work. Note: the issue of PTW does not by itself make a job safe. Timely care and attention is still a requirement. Work Permit Procedure Responsibility • The Area Manager is responsible to implement the requirements of this procedure in the Divisional Management System and to include any requirements stipulated by the Continental Shelf Authority of the operating area. • It is the responsibility of the O.I.M. to implement the requirements stipulated this procedure on the operating unit and from time to time audits the effectiveness. Work Permit Procedure Responsibility • Persons performing work under a Work Permit are responsible to carry out the work in accordance with the instructions. In the case of deviations report to the person authorized to issue Work Permits. • Persons involved with planning and persons who control the work of others are responsible to raise a Work Permit and instruct staff involved. Work Permit Procedure Definitions & Abbreviations Following definitions and abbreviations are used in this procedure: • O.I.M. The person on an installation who holds the highest authority. Alternative name – Person in Charge. • Person authorized to issue the Permit to Work: O.I.M. or his designated substitute is authorized to issue and sign off Permit to Work forms. • The job titles authorized to issue a Permit to Work must be identified on the control board. Work Permit Procedure Definitions & Abbreviations • Person authorized to carry out isolations A person who is competent to carry out isolation and who is familiar with the system on which the isolation is carried out. A list must be posted on the Control Board showing the job position of each person authorized to carry out electrical isolations and mechanical isolations respectively. Work Permit Procedure Definitions & Abbreviations • Person authorized to conduct gas checks A person who has been trained and instructed in the proper use of the gas test equipment and the acceptance criteria for performing various categories of work. A list must be posted on the Control Board showing the job title of each person authorized to conduct gas tests. Work Permit Procedure Definitions & Abbreviations • Responsible Person A person who is authorized to raise (request) a Permit to Work. A list must be posted on the Control Board showing the job title of each person who is authorized as responsible person. The list must show for each person for which category he can raise a Permit to Work. Work Permit Procedure Definitions & Abbreviations • Responsible Person …On offshore drilling units this list normally comprises: • the Rig Engineer, • the Barge Engineer, • the Senior Tool-pusher, • the Tour-pusher. Work Permit Procedure Definitions & Abbreviations • Person performing the work A person who is competent to carry out the work specified on the Permit to Work. • Control Board An arrangement where Permit to Work forms are displayed in such a way that various categories of work ongoing can be positively identified. Work Permit Procedure Definitions & Abbreviations • Control Board …The arrangement must be established in an area (e.g. Control Room) where it is constantly monitored by competent personnel and from where action can be initiated if the situation requires so. The arrangement must include separate display of ongoing work (i.e. within current 24-hour period) and systems and equipment which is in-operable for more than 24 hours or safety critical systems subject to operational restrictions. Work Permit Procedure Definitions & Abbreviations • Permit to Work File A file/record in which Permit to Work forms are kept. The file must be kept in numerical order. Work Permit Procedure Definitions & Abbreviations • Electrical Isolations Electrical isolations must be carried out on two levels: 1. Isolation of the designated equipment at the main switch board. This isolation must include physical segregation of the switch from the line. Alternatively by placing a lock on the circuit breaker. A tag must be placed on the switch panel. Work Permit Procedure Definitions & Abbreviations • Electrical Isolation …If more than one isolation is implemented on the same circuit, each individual isolation tag/lock must be identifiable. 2. Isolation at equipment end by preventing the on/off switch from being operated. The isolation must be clearly tagged. If more than one isolation is implemented on the same equipment each individual isolation must be identifiable. For equipment with remote controls a tag must be placed at each operating station. Work Permit Procedure Definitions & Abbreviations Mechanical Isolation • On pressurized systems “bleed off” must be performed prior to the isolation. • Mechanical isolation on pipelines must be performed by chaining/locking and tagging each individual connecting line. • Installation of blind flanges must be considered. On high pressure lines the isolation must include 2 barriers on lines to the high pressure system. Work Permit Procedure Definitions & Abbreviations • Bleed off The process of reducing the pressure to the ambient atmospheric level. • SJA-Safe Job Analysis A SJA shall be carried out for all activities requiring a PTW. PTW PROCEDURE The following activities must always be covered by a PTW & SJA as stipulated in Procedure 12.47: • Hot Work/Open Flame - Work carried out away from workshops(?) where hot work may be authorized on a permanent basis. Heat radiation and a requirement for a fire watch must always be considered for this category of hot work. PTW PROCEDURE • Hot Work, Spark Potential - Hot work carried out away from workshops, where hot work may be authorized on a permanent basis. This hot work category includes all work that generates or has the potential to generate fire or explosion ignition source. • Confined Space Entry – Entry into Confined compartments such as tanks, cofferdams etc. PTW PROCEDURE • Work Over the Side – routine work in the moon pool is included in this category. • Removal of guards, rails, fixed gratings – work involving removal of guards, handrails, banisters, securing fittings, grating or deck plating which is normally permanently fixed. Rigging of staging is included in this category. PTW PROCEDURE • Work Aloft – work carried out more than 2 meters above deck in an area that is not designed as a work area. Thus, normal derrick-man’s work is not included. • Electrical Work – work on live electrical systems. Work which affects the ex-proof status of any equipment or area. Work requiring shutdown of safety critical systems or work implementing operational restrictions on such systems. PTW PROCEDURE • Work with chemicals – this category includes the use or handling of any hazardous substance where the Safety Data Sheet is unavailable or work with products nominated by the O.I.M. to be covered by this procedure. • Mechanical work – this category includes any work on mechanical equipment with remote or automatic starting devices and work nominated by the O.I.M to be covered by this procedure. PTW PROCEDURE Heavy Crane Lifts – this category includes heavy loads required to pass over sensitive equipment (e.g. well testing equip.) or areas identified as safety critical. • Such areas may be identified in the Safety Case or risk assessment documents. • Unit specific restrictions have to be implemented by the O.I.M. PTW PROCEDURE Crane operations during abnormal wind speed/sea state – this category includes crane operations that are carried out outside the standard criteria applicable to the operating area. Personnel transfer – transfer by basket of personnel to/from the offshore unit, to/from between any surface vessel. The use of crane work basket is included in this procedure. PTW PROCEDURE • High Pressure Testing – on-deck testing of the tools, lines, well test equipment etc. • Work with explosives & radio actives generally personnel with specialist knowledge must perform all work with the captioned material. This category covers the use, handling, transfer and storage of such material. The requirement for a Permit to Work must be pointed out to the supervisor of the relevant service company at his arrival on board. PTW PROCEDURE Work on mooring gear – this category includes all work that affects the operability or functional capacity of the captioned equipment. Diving/ROV/Sub-sea operations – this category includes all work of this nature. Other – other unit specific requirements nominated by the O.I.M. Permit to Work - General Note: a Permit to Work is only valid on the date it is issued, alternatively the number of hours specified (maximum 12 hrs) and it can not be transferred to another person. If a job has to be handed to a new person, a new permit must be issued and the old one signed off. Any safety or operational critical equipment or technical systems which are not operationally affected by operational restrictions must be identified on the Control Board in the “24 hrs” section. A tag must be placed at each operating panel and control station for the equipment or system affected. The tag must specify the operational restrictions and it must be dated and signed by the person authorized to issue a Permit to Work. PTW PROCEDURE Raising a Permit to Work The relevant Responsible Person, in cooperation with person designated to perform the work, has to fill in boxes 2, 4, 5, 6, 7, 8 on the form. Boxes 3, 9, 10 are completed in cooperation with the person authorized to issue the PTW. Box 3 must be filled in with a consecutive number in each year (e.g. 45/95) PTW PROCEDURE Raising a Permit to Work The person designated to carry out the work must sign box 11 in order to acknowledge that all instructions are understood. If the work is subject to an Isolation, the person designated to carry out the work will go to the person authorized to implement the isolation procedure and obtain his signature in box 12 when the isolation is in force. PTW PROCEDURE Raising a Permit to Work … The person designated to carry out the work will take the PTW to the person authorized to issue the permit. The person authorized to issue the permit will check that all conditions for commencing the job are implemented and consequently fill in box 13 and sign in box 14. PTW PROCEDURE Raising a Permit to Work The person authorized to issue the permit retains the original (white) and places it on the active section of the Control Board. The person designated to carry out the work will take the copy of the permit and keep it posted at the place of work. The person authorized to conduct the gas checks will complete the relevant boxes in 16. Gas tests may have to be repeated at intervals. If the gas test readings are inside the criteria the work can begin. PTW PROCEDURE Raising a Permit to Work … If any of the stipulated gas tests are outside the criteria, remedial action must be implemented and the person monitoring the Control Board must be notified. If conditions change during the work the person monitoring the Control Board must be notified immediately. PTW PROCEDURE Closing Permit to Work When the work is completed, alternatively PTW expires, the person designated to perform the work will fill in box 15, 17, 18, 19 and contact the person responsible who will inspect the area and verify the status by filling in boxes 20, 21, 22. If the work is completed the isolation can now be lifted. This is verified by the person authorized to lift the isolation, filling in boxes 23, 24, 25. The form is now taken to the person authorized to sign off the PTW. He will sign box 26. PTW PROCEDURE Closing Permit to Work … The copy of the corresponding permit must now be removed from the Control Board and stabled together with the copy. Both copies must be filed in the PTW file. Any equipment and systems not fully operational must be identified on the 24 hours section of the Control Board. Jobs Requiring PTW • • • • • • • • • • • • • • • Hot Work Work in Confined Space Work over the side Removal of guards, rails, fixed gratings Work aloft (2 mtr) Electrical Work. (live or Ex) Work with Chemicals (no data sheets) Mechanical Work (remote or automatic start) Heavy crane lifts (when lift must pass sensitive areas) Crane Operations during abnormal wind/sea states Personnel transfer High pressure testing (on-deck testing of tools, lines etc.) Work with explosives & radio actives Diving Other PTW PROCEDURE Monitoring of PTW Routine monitoring of the “daily” use of the system shall be performed by the O.I.M. and the Safety Officer to ensure its effectiveness “on the job”. This monitoring shall be logged via a log of permits checked. Documentation and Records - Permit to Work forms - Permit to Work file Filing File retention time for Permit to Work forms is 1 year.