13BOB016 t119 BT TSO

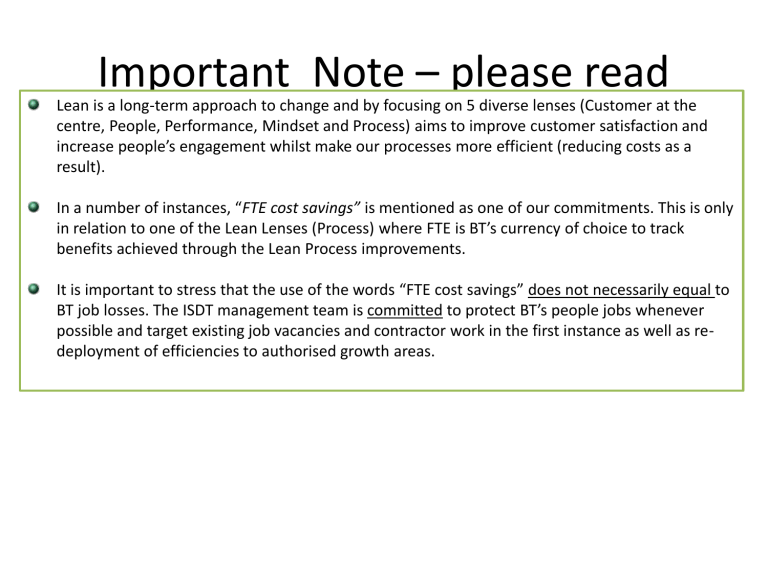

Important Note – please read

Lean is a long-term approach to change and by focusing on 5 diverse lenses (Customer at the centre, People, Performance, Mindset and Process) aims to improve customer satisfaction and increase people’s engagement whilst make our processes more efficient (reducing costs as a result).

In a number of instances, “FTE cost savings” is mentioned as one of our commitments. This is only in relation to one of the Lean Lenses (Process) where FTE is BT’s currency of choice to track benefits achieved through the Lean Process improvements.

It is important to stress that the use of the words “FTE cost savings” does not necessarily equal to

BT job losses. The ISDT management team is committed to protect BT’s people jobs whenever possible and target existing job vacancies and contractor work in the first instance as well as redeployment of efficiencies to authorised growth areas.

Why Lean, Why now?

Challenging business environment

Play the video

It’s a challenging market:

• Fierce competition

• Bandwidth requirements are increasing

• Our customers want more for less

So...

We need to offer excellent customer experience, consistently.

We need to deliver the right things efficiently, at the right price for our customers.

Play the video

To respond to this we need to:

• Deliver competitive, high quality and secure services

• Work with our customers to better understand what they want

• Stop doing the things which our customers don’t value.

So...

that we can get better at what we do and make our people’s lives easier.

And at the same time, play our part in helping BT grow.

Executive Summary Slide

Our commitment to Charter Objectives

(33 FTE and 5 FTE cost avoidance vs. 29 FTE in charter, CE Improvements and LWOW Maturity)

Deep-Dive on Inbound Contact Global

Benchmarking analysis

Cost and Revenue

Future State Vision

See Notes slide – FTE is the currency used to measure process improvements but does not necessarily equal to BT Job reductions. There’s a number of ways of achieving this goal whilst minimising impact to our people (e.g. targeting vacancies and contractors)

As-Is vs. TC1 analysis

Our TC1 commitments on People, Performance and Mindset

Our TC1 commitments on CE & Financials

By focusing on 5 diverse lenses

(Customer, People, Performance,

Mindset and Process) Lean aims to improve the way we deal with our customers and with our people whilst making BT more cost efficient

COMMITMENT PRESENTATION

REDESIGN AND TC1

LEAN WAVE 3 ICSD

MISCELLANEOUS PRODUCTS

Inbound Contact Global Operator

Rankings

This slide is specific to Inbound Voice. You can find your process specific commitment slides Here

8

BT

7

Verizon

6

Orange

5

T-Systems

4 Cable & Wireless

3 AT&T

Telefonica

2

2,50 3,00 3,50 4,00 4,50

Execution

(Scale 0-10)

5,00

Source Data provided by OVUM

5,50 6,00 6,50 7,00 7,50

Inbound Service

Surround

Inbound Pricing

Inbound Contact Global competitive story

This slide is specific to Inbound

Voice. You can find your process specific commitment slides Here

Inbound Network

Capacity

Largest global network

BT

Best in market

Priced at a premium to competition

Orange

Large network coverage.

Recently expanded using Mobil sites for access. Issues with

VoIP.

Service Issues on some routes

No consistency in pricing

C&W

Fairly large network on limited set of routes.

Focused on low end of market except for Spain

Good service Spain

Good service on limited routes

Tends to ‘buy’ business

Inbound Reports

& Controls &

Analytics

Bundles

Feature

Functionality

Automatic reporting with ‘call traffic’ reporter’ tool. Allows customer plan changes

Best-in-class in some cases. Specifically when bundled with IVR or MCC.

Features are included in

Pricing

Greatest reach of all competitors. Most robust functionality when combined with Interactive

Voice Response (IVR ) and

Multimedia Contact

Centre (MCC)

Source Data provided by OVUM

Limited reporting capability. Good customer control of

Routing options

Strength when bundled with data transport

Varied. BT functionality better at high end. Missing reach of CCS.

Adding an MCC like platform

Specialised reports for larger customers. Allow customers to change switched terminations on the fly

Limited bundling

Limited ability better at high end. Missing reach of CCS

Best in class Weakness

Verizon

Fairly large network on limited set of routes.

Focused on low end of market except for Spain

Service has suffered over recent years

Strong when combined with domestic US

Limited reporting capability. Good customer control for US / iTFS applications

Strong when bundle with domestic service offerings

Varied. Missing reach of

CCSI. However, better functionality for domestic services

Strength Neutral

Inbound Contact Global As Is Waterfall

specific commitment slides Here

Overtime

Standard Allowances

Unavailable Time

Waste 40 FTE

9 FTE

5 FTE

1.5 FTE

45 FTE 45 FTE

27

FTE

See Notes slide – FTE is BT’s currency of choice when measuring process efficiency, hence the reason why it is used in the chart, along with hours equivalent.

17 FTE

Future State

Inbound Contact Global Process redesign overview

Key changes

This slide is specific to Inbound Voice.

You can find your process specific commitment slides Here

1.

Replace current manual Data Capture Form (DCF) & provide means for electronic data entry into VLP by account team.

2.

Remove manual intervention for design template. Auto-populates.

3.

Significantly reduce PTT dwell time by creating pre-built inventory of International access services. (Wait time in BT control)

4.

Enable partial self provisioning to the customer for endpoints & routing features. Access retained within BT entity.

5.

Auto generation of BT dial plan to support customers & automated billing population.

6.

System generated notification of order closure to the customer via VLP. (Voice Logical Provisioning)

Future State – Process

Direct Sales Entry via Portal

1

Design Template

Auto-populates from Portal

2

Prebuilt

Ownership of

INT Access

3

Customer self

Provisioning capability

4

System

Generated

Customer

Inventory

5

System

Generated

Notification of

Order Closure

6

Indicates standard order flow approx 75% Indicates support required for complex orders equating to approx 25%

Performance benefits

1.

Simplified on-line ordering service with built in validation checks to reduce errors and improve customer experience.

2.

Auto populated configuration template with critical data including built in validation, reduces touch time and ELF’s

3.

Reduce PTT dwell time from an average of 64 days to 1 working day ultimately improving overall cycle time and Customer Experience.

4.

Increasing customer control of their call features and routing with self provisioning capability, ultimately reducing cost of delivery.

5.

Provides real time inventory capability, reduces touch points and improves customer access to their own inventory.

6.

Replaces manual notification and multiple touch points removes cost, and reduces delays in order process.

Target Condition 1

Inbound Contact Global Process

Key changes

This slide is specific to Inbound Voice.

1.

redesign overview

2.

Create PTT inventory database in order to own complete E2E delivery for access ordering.

You can find your process specific commitment slides Here

3.

Re-design Telephony Server B number analysis to incorporate generic command line as opposed to single entry

4.

Introduce bulk upload capability within configuration management function to support increasing order volumes .

5.

Graduated reduction in dual platform builds as Firebird migration progresses.

6.

IPMS re-design improvement. Introduction of mandatory fields to prevent re-work on network DDI allocation and bulk change functionality.

Sales Order

Handling

(Other LOB)

Order

Submitted

Order Access

Delivery of

Service

Configuration

Signoff &

Maintenance

(Other LOB)

Rework –

Missing or incorrect data

25% Cost reduction

End-End Delivery

Performance benefits

1.

Remove waste in rework at both order and configuration stages preventing errors and improving RFT, ELF’s and Customer Experience.

2.

IFF PTT dwell time reduction from an average of 64 days to 1 day for fast track requests, improving Customer Experience. (VOC)

3.

Cycle time improved by 4 min’s per service delivered by redesigning command line entries into Telephony Servers.

4.

Reduction in processing time by 6 min’s/service with the introduction of bulk upload capability of command line data into GUI interface.

5.

Firebird Project will have achieved migration of just over 70K services by the end of TC1 reducing the need for double keying.

6.

Prevents dual allocation of network DDI’s, removing waste and improving process flow and Customer Experience.

VERTICAL LENSES

DENNIS GREEN

Managing our Performance

Key Issues Current State:

People want to do the best jobs but the processes hinder them (ABRB Q3

Care Report).

Team measures are not clearly aligned to the Voice of the Customer (Lean

Maturity baseline & vertical data collection).

Teams feel process discussions are top-down rather than bottom up or two-way (ABRB Q3 Care Report & Lean Maturity baseline).

TC1

Future

State

The processes hinder my performance.

AS IS

I understand and deploy standard work and engage proactively with my manager during process confirmation. I work with colleagues who do the job to shape standard work.

Lean Ways of

Working are part of my team’s DNA.

TC1

What will we do?

Deploy standard work and process confirmation.

How are we going to do it?

Managers use performance dialogue to identify tasks appropriate for standard work; those who do the work to shape the standard work. Managers do process confirmation weekly.

How will we know it’s worked?

• Lean Maturity weekly self-assessment.

• Documented standard work.

• Managers agree with teams daily standard work.

Performance Board and huddles operating as BAU.

Improve the % of orders we receive into our processes right first time.

Set up Performance Boards at each level of the organisation with cascade up and down. Standard work for managing the

Performance Board and daily huddles.

Managers commit to identifying their clean order % and to working with upstream partners on root cause analysis to identify reasons for unclean orders.

• Lean Maturity weekly self-assessment: Bronze level achieved.

• Positive feedback from the team. Improvement ideas managed at the appropriate level and contribute towards the future state.

• Improved % of clean orders (baseline dependent on A3 current condition).

Organising our people and developing their skills

Key Issues Current State:

People feel their skills are not fully utilised and they lack opportunities to learn new skills (Lean Maturity baseline & Job Satisfaction Survey).

Job roles, gradings and working practices are not directly aligned to the Voice of the

Customer (proven vertical hypothesis & HR data collection).

Some teams are dispersed across many locations in the UK and abroad, making it harder to share learning about how best to deliver for our customers (Trade 28b vertical data collection).

TC1

I feel my skills are not fully utilised and I want to develop new skills .

AS IS

Future

State

I will use the skills matrix to work with my manager to develop a quality

PDP aligned to meet future demand.

My team’s skills matrix is constantly updated and visible, and fully aligned to VOC. Every team member has a tailored development plan aligned to this.

TC1

What will we do?

How are we going to do it?

Skills Matrices deployed.

All teams to have up-to-date skills matrices which are visible and discussed at performance dialogue.

How will we know it’s worked?

• Lean Maturity weekly self-assessment.

• Standard work agreed by teams to review and refresh their skills matrices to ensure alignment to their Voice of the Customer.

Process level multi-skilling started.

Document handover procedures between teams in Miscellaneous

Products.

Managers use the team skills matrix as part of performance dialogue. Managers work with their teams to identify multiskilling requirements aligned to their Voice of the Customer.

Nominated representatives from each trade to work jointly on an

A3. Required output is an agreed approach and template to summarise key handover information.

• Multi-skilling training commenced to impacted personnel.

• Completed A3 and delivered handover document.

• Standard work deployed for completion.

• Reduction in handover issues between trades (baseline TBA as part of

A3).

Having the right mind-set

Key Issues Current State:

Managers spend too much time on non value-add activities rather than coaching their teams and “going to gemba” (vertical data collection, Manager Time Analysis).

We fire-fight rather than use a structured approach to problem solving (ABRB Q3 Care Report,

Lean Maturity baseline, Team member feedback).

Teams are not fully clear on their purpose and its alignment to VOC (proven vertical hypothesis,

Lean Maturity baseline & VOC data collection)

Teams are concerned about the impact of Lean on their jobs (ABRB Q3 Care Report).

TC1

Future

State

My manager doesn’t spend enough quality time with me coaching at the coalface.

AS IS

I understand and use problem solving techniques and my manager coaches me on them.

My manager is a great coach, who spends 50% of his/her time with the team, helping us to stretch our capabilities.

TC1

What will we do?

Managers spend 50% of their time with the team.

Coaching on structured problem solving

(A3) is BAU.

How are we going to do it?

All managers complete A3s on how they spend their time and then complete a STOP/START/CONTINUE exercise to identify and remove non-value add activities from their diaries.

Equip managers and team members with structured problem solving skills which we will actively use at all levels.

Managers deploy coaching Kata to upskill teams on A3 methodology.

How will we know it’s worked?

• Completed Manager Time Analysis tracker at week 15 to gauge % of time spent coaching the team.

• Improvement in Job Satisfaction Survey questions: “Does your manager spend quality time with you discussing your work?”; “Do you have the opportunity to work with your team to solve problems?”

• Lean Maturity weekly self-assessment.

• Clear evidence we are resolving root causes rather than symptoms.

• Observation at performance boards to ensure A3 approach being used.

Target Condition 1

Saving Summary

Process re-engineering

Effort Waterfall – TC1 Commitment

7 FTE

(productive time)

Standard allowances currency of choice when measuring process efficiency, equivalence converting productive hence the reason why it is used in Total time to FTE the chart, along with hours equivalent.

6000,00

TC1 Commitment

Overtime

1.5 FTE

6.5 FTE 1 FTE saving through LWOW 5 FTE 7.2 FTE

Standard Allowances

Remaining Waste

5000,00

Outside Diagnostics

23 FTE 25 FTE saving

1 FTE saving re-engineering

4000,00 146

FTE

138

FTE

1+ 3

FTE

7.9 FTE

12.9 FTE

7.4 FTE

Saving

25

1

7

33

3000,00

50 FTE

115

FTE

2000,00

115

FTE

3.6 FTE

0.1 FTE

1000,00

36 FTE

0,00

Total within Subwave

-1000,00

Standard allowances outside diagnostic

Outside diagnostics &

Extrapolation

Standard Allowances inside

Diagnostic

Total available within diagnostic

Nonprocessing time

Total Processing time Processing Value demand

Processing

Failure

Demand

NVA Rework

NVA (Other)

NNVA

Activities

VA activities

TC1 Efficiencies Summary

See Notes slide – FTE is the currency used to measure process improvements but does not necessarily equal to BT Job reductions. There’s a number of ways of achieving this goal whilst minimising impact to BT people (e.g. targeting vacancies and contractors)

Process

Name

CTQ Requirements

Trade 12

Trade 6

Trade 28B

•

•

•

Specific detail on escalations

Quicker Cycle Time (E2E)

Quicker Cycle Time (with our suppliers)

RFT Delivery •

• Flexible response to in-production changes

• Quicker Cycle Time

• RFT Delivery

• Quicker quotes

• Handover pack accuracy with circuit and contact details

• Specific detail on escalations

• Quicker Cycle Time

• RFT Delivery

Percentage of

Population in

Scope

VA %

(within the process flow)

Number of

FTE

39% FTE

49% FTE

7% FTE

39%

24%

8%

57 FTE

71 FTE

10 FTE

TOTAL

95% (plus managers)

138 (out of

146 in scope)

TC1 Efficiencies

Voice Outbound = 6 FTE

Voice Inbound = 5 FTE + 5 FTE Cost Avoidance

LWOW = 1 FTE

LAN = 9 FTE

IPT = 3 FTE

AVAYA = 5 FTE

DST = 1.5 FTE

IPLC = 2.5 FTE

33 FTE efficiencies + 5 FTE CA

(23% of 146 in-scope)

Target Condition 1

Performance, Mindset and Process) Lean aims to

Commitment Summary

Making processes more efficient improve the way we deal with our customers and with our people whilst making BT more cost efficient

Managing our performance

• Reduced cycle time (specific targets vary by process)

• We will work with our teams to identify and shape standard work for key tasks; managers will undertake process confirmation.

• Saving 33 FTE (23%) due to process re-engineering activities enabled by; o Creating Flow o Controlling Flow o Managing Demand

As per Notes slide, FTE does not necessarily equal to BT job reductions, there are a number of ways to achieve these targets whilst minimising the impact to BT people

• Performance boards and performance huddles will be

BAU at all levels of the organisation.

• We will work with our upstream partners to identify and rectify the root causes of unclean orders entering our processes. We will establish a robust ‘as is’ picture first before planning and deploying improvements.

Listening to our

Customers

• Reduced end to end cycle time

• Already very good RFT service

Having the right mindset levels maintained or improved

• Improved escalation and KCI process

• Local CE metrics tracked via

Performance Boards

• All managers will complete A3s on how they spend their time and do a STOP/START/CONTINUE exercise to remove non-value-add activities from their diaries. They will spend more of their time where the work takes place coaching their teams.

Organising our people and developing their skills

• All teams will have visible, up-to-date skills matrices which align to VOC, and are reviewed during performance dialogues.

• Multi-skilling training will be rolled out based on forecast demand and team skills matrices.

• We will equip managers and team members with structured problem solving skills which we will use at all levels. Managers will deploy coaching Kata to upskill teams on A3 methodology to make structured problem solving BAU.

• Handover procedures between teams in

Miscellaneous Products will be developed and documented, underpinned by standard work.

BACK UP SLIDES

CTQ Requirements

See Notes slide – FTE is the currency used to measure process improvements but does not necessarily equal to BT Job reductions. There a number of ways of

As Is Summary

BT people (e.g. targeting vacancies and contractors)

Percentage of Population in Scope

VA %

(within the process flow)

Process

Name

Trade 12

Trade 6

Trade 28B

• Quicker quotes

• Handover pack accuracy with circuit and contact details

• Specific detail on escalations

• Quicker Cycle Time

• RFT Delivery

TOTAL

• Specific detail on escalations

• Quicker Cycle Time (E2E)

• Quicker Cycle Time (with our suppliers)

• RFT Delivery

• Flexible response to inproduction changes

• Quicker Cycle Time

• RFT Delivery

39% FTE

49% FTE

7% FTE

95% (plus managers)

39%

24%

8%

Number of FTE

57 FTE

71 FTE

10 FTE

138 (out of 146 in scope)

Taking re-design to the teams

1) Show Team members the 4FM

3) Show rework, and explain this is where some of the improvements come from

30%

2) Explain waste, and why a step is

NVA etc.

Step 1 Step 2 Step 3 Step 4

Show list of

Improvements, and how they fit into the process.

Explain TC1, and what impact that has on the process

Explain the tools and techniques that they will learn to help complete the improvements – A3 masterclass