Research and Teaching Plan

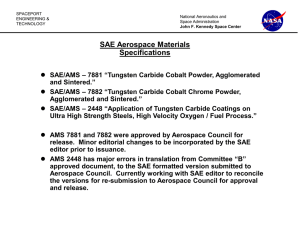

advertisement

RESEARCH AND TEACHING PLAN Presentation to: Department of Information and Decision Sciences College of Business Administration University of Texas at El Paso 1 PRESENTATION OUTLINE • Describe an “interesting” research project • Present an overview of current research and teaching interests/projects • Discuss my vision for the future 2 “Interesting” Research Project: KABOM knowledge/activity based operations modeling With Carey McCleskey, Edgar Zapata, Russ Rhodes Advanced Projects, NASA Kennedy Space Center, FL 3 Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 4 Introduction do you know? • The cost per space shuttle flight? • During the design of shuttle, the designers expected/planned the time between flights to be: a) < 1 week b) < 1 month c) 1 - 2 months d) 3 - 4 months e) > 5 months • From the above, what is the current average time between flights? • What is the shuttle’s design reliability? 5 Introduction the design to operations gap • A view of operations by the designers • Operations at the Orbiter Processing Facility (OPF) today. 6 Introduction the causes • Space vehicles are complex systems • Operations was not a primary concern of designers – Design process focused on the rocket equation – Primary operations concern: how do we use existing facilities – Once the vehicle worked - up to Kennedy to make it work. • Minimizing cost was an objective (NASA’s budget has had its ups and downs), BUT it was a “myopic” view, minimize development cost or minimize manufacturing cost, seldom a total cost view. 7 Introduction things are changing • NASA is changing. – Moving from a service provider to a support and monitoring entity • Space business environment is changing – Commercial launch capabilities have increased. • Facilities in old USSR, Guyana, Brazil, China, and even sea launches – Need for launches has increased, exceeding capacity – Interest in other commercial uses of space • Hilton Space Hotels?- spacehotels – The X Prize 8 Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 9 Previous work vision spaceport • Team approach > ground operations modeling – Includes NASA KSC and Ames, Lockheed Martin, Boeing, SIAC, and other related government, university, and private organizations. – My role: NASA fellow for the summers of 1998 and 1999. • Objectives: – Develop models to asses new designs: spaceport operations - life cycle costs – Educate vehicle designers on spaceport operations – Connect model to design/development models and manufacturing models 10 Previous work vision spaceport • First approach – Knowledge based utility functions – Mapped vehicle inputs to spaceport functions. • Functions provided sense of direction: was the design an improvement over the baseline for a function. Cost and times derived from the deviation • Developed a tool in Excel/VB: AATe. – NASA Copyright. – Used in several studies at Marshal and Langley. – Modeling approach was applied in a second tool application developed by CCT. 11 Previous work vision spaceport Umax $ or CT Umin 0 1 F(Mc)=Si1.I, j1..Ji (Xij*SiMc/(Sy =1..ISyMc)) I Ji Xij SiM F(Mc) # of design/assessment questions # of options for design question i Value of option j for design question i (0 - 1) Strength of relation, design/assessment question i to Mc Score for spaceport function M and characteristic c 12 Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 13 Knowledge/Activity based Operations Modeling (KABOM) • Objective: – To asses the operational requirements of a vehicle design. Determine: • Cost per flight (cost per pound) and Cycle time • Processes and Resources required – Present to vehicle designers the processes required for operation – Address limitations of the utility function approach • Dissipate effect an expert will have captures • Difficult to calibrate as inputs increase • Limited representation of reliability effect 14 KABOM Basics Origins • Related to ABC models - used in manufacturing and SCM • Similar to the approach used by Christenson and Komar (1998) to model/ analyze reusable rocket engine operability • Primarily for online functions (landing, turnaround,..) • Model is a component of total spaceport analysis model which should capture the other spaceport modules (not in flow). – This is a subset of an LCC model that includes development, manufacturing, and operations 15 KABOM Basics The RLV design • The model characterizes a RLV architecture/concept by I design variables – I represents a particular option of the vehicle, for example ceramic times, ultra high density ceramics, SOFI. – The binary variable di is used to represent the inclusion of a design option; di = 1 if the design option is included in the design and di = 0 if not. 16 KABOM Basics The RLV design • This model characterizes a RLV architecture/concept by J vehicle characteristics/ operational drivers. – The vehicle characteristics J represents measures that will drive operational cost or time, for example the number of fuel cells or the area covered by a type of thermal protection. – The variable qj is used to represent the quantify of an operational driver, qj > 0 if that operational driver exists in the design and qj = 0 if not. 17 KABOM Basics The Activities • There are A spaceport activities. – Activities relate to one or more design variables. – The binary variable sa represents the inclusion of that activity in the activity set for that design; sa = 1 if that activity is part of the activity set and sa = 0 if it is not. – The determination of the activity set is determined by knowledge based equations. I.E.: s3 = s7 = 1 , if d1 + d12 = 2 0, otherwise 1 , if d11 = 0 and d123 = 1 or if q56 > 100 0, otherwise 18 KABOM Basics Activity Characterization • Three characteristics for each activity: activity time, activity cost, and need percentage. – The process time for an activity a; pa, is determined by a knowledge based equation. • p1 = UNIF (35, 100) x q13 hours • p5 = EXPO (3 x q38 ) minutes • p42 = 50 x q38 minutes – The cost per activity a; ca, will be characterized in a similar fashion. • c1 = p1 x $14,000 • c81 = $10,000 + $120 x q39 • c22 = $75,000 19 KABOM Basics Activity Characterization • Continued: – The need percentage for an activity a; na, is determined by a knowledge based equation. • n19 • n7 = = 10% , if e45 = 1 30% , if e46 = 1 100%, otherwise 50% , if q92 < 2,000 100%, otherwise – From these values, we can determine the expected average time for an activity, E’(pa): E’(pa) = na x E(pa) 20 KABOM Basics Process Modeling • Spaceport process model – All A activities are integrated into a spaceport process model. – The process model captures precedence constraints and possible alternative routes. LAUNCH TURNAROUND TRAFFIC CONTROL TERMINAL LANDING ASSEMBLY/ INTEGRATION EXPENDABLE ELEMENTS 21 KABOM Basics Resources • The spaceport has R resources – Each resource r has a set r of assigned activities. – Each resource r has a per unit of capacity fixed operational cost, fcr and one time acquisition cost, acr. – The capacity for a resource r, xr, is estimated by: xr. = Round up(F x S for all a r [E’(pa)] / T) F = Round up(D/VC) where T = Time of spaceport operation D = Annual demand (lbs.) F = Number of flights per year VC = Vehicle per flight capacity 22 KABOM Basics Fleet Size • The system requires a fleet of Vn vehicles to satisfy annual demand – The process network and average expected activity times are used to determine the set of activities in the critical path . Vct = S for all a [E’(pa)] Vfr = T / (Vct + Vot ) Vn = Roundup (F / Vfr) where Vct = Vehicle ground cycle time Vot = Vehicle orbit time 23 KABOM Basics Architecture User Activity Generator Activity Library User Interface Critical Path/ Resource Capacity Generator (Process Model) Report Generator Process Model/Simulation Cost Generator Improvement Agent 24 KABOM Basics Simulation Model • Why the use of simulation: – Better representation of a dynamic environment. – Estimate bottlenecks, resource utilization, queues, ..., costs (VS Team objective 1). – Provide designers a graphical (animation) representation of their system at work.. (Team objective 2) – Allows the evaluation of scenarios. • For example, a version of the model could be developed where two types of vehicles can be modeled (I.e. Shuttle and Venture Star). 25 KABOM Basics Improvement Agent and Cost Calculations • Improvement Agent – Heuristic to improve total performance. • The heuristics will recommend changes to resource capacity and/or fleet size parameters. Several iterations are conducted (simulation repeated) until cost improvements are not obtained. • Cost calculations – Activity costs tracked during the simulation run. – Total costs include activity costs and resource related costs – Vehicle acquisition costs are included as an input from the designers. 26 Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 27 Project Extensions • Approach used to develop design analysis tools for manufactured products (an advanced ABC analysis) – Help product designers estimate costs/processes – Evaluate what if scenarios in a design (mfg processes) – A “real time” version of the model could estimate the effect of a new product on current system load. • • • • Order for “customized product” arrives Tool determines activities, costs, .. Order is added to current production schedule Decision on taking the order or how to schedule it 28 Outline for this section • Introduction • Previous work • KABOM • Project Extensions • Project Status 29 Project Status • A prototype was developed last summer while at KSC • Student project on a web based version of the AATe • Grant proposal - excellent evaluations, waiting for funding. 30 PRESENTATION OUTLINE • Describe an “interesting” research project • Present an overview of current research and teaching interests/projects • Discuss my vision for the future 31 Overview Of Research/ Teaching Interests And Projects • Research – – – – Production Planning Supply Chain Management IS/OM/Simulation Interaction Space operations • Teaching – Games – Excel applications – Advanced POM courses/ APICS/ ERP (Future) 32 Production Planning Research • Cellular manufacturing systems – Development of tools and models to plan/schedule on systems where production resources are organized as cells and products into common families. – Work with Jeet Gupta from Ball State University – Paper in progress • Parallel Machine Scheduling with Multiple Criteria – Development of heuristics for difficult multi-criteria problems in the parallel machine setting. – Work with Jeet Gupta and Kazou Nakatani (FGCU) – Two papers accepted for publication, several in progress. 33 Supply Chain Management Research • Supplier Decision Making – Evaluation of the role transportation plays on supplier decision making. – Work with John Tyworth from Penn State University – One paper accepted for publication • Supply Chain Simulation – Development of simulation models for supply chain environments in order to evaluate transportation and scheduling priorities.. – Work with John Tyworth 34 Interaction of IS, OM, and simulation • Supply Chain Management – Development of architecture to support “real time” DM.. – Utilizes simulation to investigate “what if ” scenarios. – Work with J. Tyworth and K. Nakatani. • Project Management – Development of architecture to support Web based project management. – Utilizes simulation to evaluate the CP and effect of “what if ” scenarios. – Prototype developed and tested at NASA. – Work with K. Nakatani. 35 OM Games/Exercises • Development/application of class games to enhance student learning – Beer game from Jacobs web page – In-class exercises after “lecture”. • QFD - development of a QFD diagram for a business class • SPC - process simulation – JIT game with Lego/remote controlled cars (Rokenbok) 36 Excel Applications • Use of Excel for operations analysis – – – – Data analysis/ “real time” behavior graphs Queue models Forecasting Capacity Analysis • Use of Excel for quantitative methods course – Math Programming – VB front end – “Real world” application development 37 PRESENTATION OUTLINE • Describe an “interesting” research project • Present an overview of current research and teaching interests/projects • Discuss my vision for the future 38 My vision of the future research • Continue research on all four areas – SS: applications of KABOM to manufacturing, IS/Simulation, Production Planning, SCM – Publication in leading journals, – Long term - editor of leading journal • Develop relationships with manufacturers in El Paso and Juarez. • Manufacturing-Logistics Center? - outreach program. – Foster knowledge creation in the ML field - faculty and student projects, grants, .... – Foster business2business partnerships/creation of new businesses – Continuing education programs? 39 My vision of the future teaching • Teaching/POM – Continue development of teaching games • Program/curricula development – Graduate program in Manufacturing Logistics? – Integration of APICS certification into some undergraduate and graduate courses? – Revision of POM undergraduate program? – ERP integration to the POM program? • Link undergraduate POM students to faculty research projects 40 •Thanks for your time •Questions? 41