Superconducting_generators_for_wind_turbines_GE

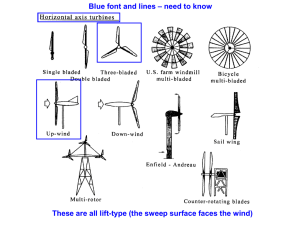

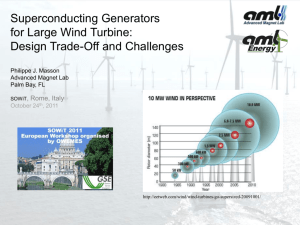

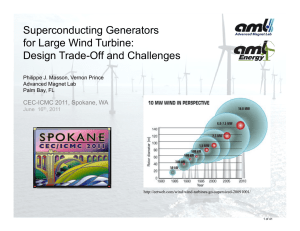

advertisement

Superconducting Generators for Large Wind Turbines Ozan Keysan o.keysan@ed.ac.uk Institute for Energy Systems The University of Edinburgh 26/09/2012 Motivation BARD 5MW In 2020, 85% of offshore wind turbine installations will be larger than 5 MW Global Offshore Wind Energy Markets and Strategies,2009 Wind Turbines: Constantly Growing How big? UpWind Project: A 20 MW Wind Turbine is Feasible www.upwind.eu Superconducting Machines Converteam (ALSTOM): 5 MW HTS Siemens: 400 kW Courtesy of Siemens, Converteam (ALSTOM) Power Applications : Electrical Machines 36.5 MW, 120 rpm (U.S. Navy, AMSC) Courtesy of AMSC Mass of Direct-Drive Generators Enercon 4.5 MW, 13 rpm 220 tonnes Harakosan 1.5MW,18 rpm,47 tonnes All data available at goo.gl/ZZivv (*) D. Bang et.al. “Review of Generator Systems for Direct-Drive Wind Turbines,” 2008, Mass of Direct-Drive Generators All data available at goo.gl/ZZivv Reliability of Wind Turbines ~1MW, 1500 onshore turbines Hahn, B., & Durstewitz, M. (2007). Wind Energy-Reliability of Wind Turbines. Reliability? Issues with Superconducting Generators Cooling System Cryogenic Couplers Electric Brushes Transient torques on SC Demagnetization for Bulk SC AC losses on SC wire SeaTitan AMSC, 10 MW, 10 rpm Direct-drive superconducting generator Transverse Flux HTSG Transverse Flux HTSG Pros Single Stationary SC Coil No Brushes No Cryogenic Coupler Bidirectional flux High Torque Density Cons Magnetic Attraction Forces 3D Flux (Soft magnetic composites needed) Linear Prototype Linear Prototype Some Photos & A Short Video Next Stage A Superconducting Field Winding Simple Insulation LN2 bath Design for Large Wind Turbine 10 MW 10 rpm Mass/Cost Estimation THANKS