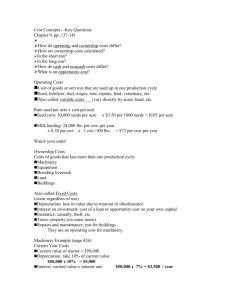

FACTORS IN MACHINERY SELECTION

advertisement

Economic Issues Regarding The Implementation Of Autonomous Machinery In U.S. Agriculture Jordan Shockley Agricultural Economics How much will they cost? What are the benefits? Are they more profitable than conventional machines? How many machines will I need? Insurance? Labor impacts? Risk? Environmental impacts? Energy consumption? More questions than answers!!! OBJECTIVE: Purchase the machine that will complete the required task within the time available for the lowest possible cost. Machinery Size Timeliness Costs Field Capacity (FC): Acres per hour FC = Speed(mph)*Width(ft.)*Efficiency(%) 8.25 Minimum Field Capacity (MFC) –Acres per hour MFC = Acres to Cover Hours per day * Days Available Climate Machinery Operations Soil Moisture COMPACTION! Solutions???? Field Days Needed (FDN) = Acres to Cover Hours per day * FC http://www.nass.usda.gov/Statistics_by_State/Kentucky /Publications/Crop_Progress_&_Condition/index.asp Timeliness Cost Ownership Cost Operating Cost Timeliness costs arise due to the inability to complete a field operation in a relatively short period of time. How much time? Difficult to estimate! Varies year to year based on weather and crop prices. Depreciation = (Cost - Salvage Value)/Useful Life Interest= Avg Value of Investment * Interest Rate Avg Value = (Purchase Price + Salvage Value)/2 Property Taxes = Purchase Price * Tax Rate Insurance = Purchase Price * Insurance Rate Labor = Wage * (1/Field Capacity) Fuel, oil, lube = Fuel Price*1.15*Fuel Consumption Rate*(1/Field Capacity) Repairs and maintenance = R&M Factor*Purchase Price*(1/Field Capacity)/Total Hours Used ALL COSTS ARE PER ACRE!!! Relevant machinery data can be found in ASABE Standards form D497.5-Agricultural Machinery Data 8 Row No-Till Planter Speed: 6 mph Width: 20 feet Efficiency: 70% FC= 6*20*.70 = 10.18 acres per hour 8.25 500 Acres, 13 hours per day and 4 suitable field days MFC= 500 = 9.62 acres per hour 13*4 This planter CAN plant all 500 acres. Tractor 130 hp Tractor Purchase Price: $91,323 Salvage Value: 40% Useful Life: 8 years Interest Rate: 8% Fuel Consumption: 8.75 gal/hr R&M: 15% Annual Use: 600 hours Planter 8 Row No-Till Planter Purchase Price: $34,072 Salvage Value: 45% Useful Life: 8 Interest 8%: R&M: 45% Annual Use: 150 hours Tractor Planter Depreciation Depreciation ($91323-$36529)/8 = $6849 Interest ($91323+$36529)*.08 = $10228 $10228/2 = $5114 ($34702-$15616)/8 = $2386 Interest Total Ownership Cost Total Ownership Cost $6849+$5114 = $11963 $2386 + $2013 = $4399 (34702+$15616)*.08 = $4025 $4025/2 = $2013 Total Machinery Ownership Cost for Planting = $16,362 per year Labor $12*(1/10.18) = $1.18 per acre Fuel & Lube $3*1.15*8.75*(1/10.18) = $2.97 per acre R&M Tractor .15*$91323*(1/10.18)/600 = $2.24 per acre Planter .45*34027*(1/10.18)/150 = $10.03 per acre Total Machinery Operating Cost for Planting = $16.42 per acre Ownership Costs = $16,362 Operating Costs = $16.42*500 = $8,210 Total Machinery Costs = $24,572 This planter and tractor can get planting done in a timely manner and it will cost $24,572 per year. If the field capacity of the machine is less than the minimal field capacity required you will need a larger planter or you might go with 2 tractors and planters If you own more than one machine, ownership costs must reflect multiple machines. If the machine is going over the field more than once, that must be incorporated into the machinery operating costs by multiplying the total cost per acre by the number of trips across the field