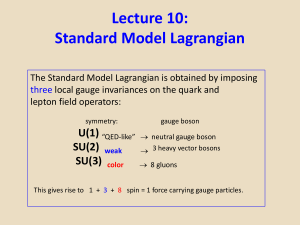

Engine Measuring

Engine Measuring

Vernier (Dial) Caliper

Useful because it can read inside and outside measurements.

Use only as a

“rough” guide.

Add the reading on the blade to the reading on the dial.

Micrometer

The most used measuring instrument in engine service and repair

Each revolution of the thimble moves the spindle .025”.

The thimble is graduated into 25 equally spaced lines so ….

Each line represents

.001”

Crankshaft Measurement

Measure for out-of-round

Measure the journal in at least six different positions across the diameter at 60 degree increments. This should be done at the same horizontal position.

Subtract the highest from the lowest to factor outof-round.

Crankshaft Measurement

Crankshaft taper – measure the journal at two different horizontal positions across the journal and subtract to factor taper.

Telescopic Gauge

Used in conjunction with a micrometer to determine the inside diameter of a hole.

The gauge is inserted until contact is present and then locked.

A micrometer is then used for measurement.

Use only if necessitated.

Small (split)-ball Gauge

Similar to a telescopic gauge in that it is used in conjunction with a micrometer to determine the inside diameter of a hole.

Small (split)-ball Gauge

The gauge is inserted until contact is present and then locked.

A micrometer is then used for measurement.

Used for small bores.

example: valve guide

Split-ball Probe

More accurate than a split ball gauge

Often used for larger bores

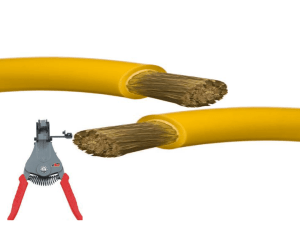

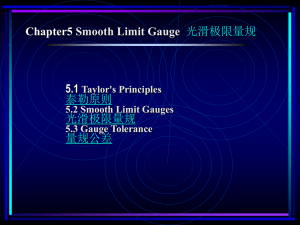

Feeler Gauge

An accurately manufactured strip of metal used to factor the gap or clearance between two components.

Used for:

Piston ring gap

Piston ring side clearance

Connecting rod side clearance

Warpage

Straightedge

A precision ground metal used to check to flatness of a component. Used for:

Cylinder heads

Block deck

Measures variations from zero. 14-21

Used to check

Runout

Crankshaft endplay

Valve guide wear

Dial Indicator

Dial Bore Gauge

The most accurate way to measure bore diameter, taper or outof-round.

Gauge must be “set-up” and zeroed before usage.

Used for:

Cylinders

Main bores

Connecting rod bores

Bearing bores