Process Improvement - SSD Global Solutions

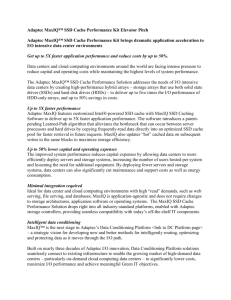

advertisement

A Little More History Juran and Deming Lean Roots are in Total Quality Management (TQM) Total Quality Management and continuous improvement Bell Telephone employee and Professor Walter Shewhart. W. Edwards Deming – attributed with saving the Japanese economy after WWII Joseph Juran Also traveled to Japan Quality Control Handbook 1962, updated 2004 Not to be reprinted without the expressed written permission by SSD Global, Inc. 2 Deming and Juran - TQM Cost of Quality – Cost of Poor Quality Quality Circles “Quality does not happen by accident it must be planned“ Juran Demings 14 Points Not to be reprinted without the expressed written permission by SSD Global, Inc. 3 Both Believed Quality means conformance to requirements, not goodness Quality is achieved by prevention, not appraisal Quality has a performance standard of Zero Defects, not acceptable quality levels Quality is measured by the Price of Nonconformance, not indexes Not to be reprinted without the expressed written permission by SSD Global, Inc. 4 Important People Juran Deming Shewhart Balridge Taguchi Lean Six Sigma 3 Ps 5 Laws of Lean Six Sigma * 5 C Model * 5 S Model* SSD Global Working with Different Models and Numbers Lean Six Sigma SSD Global Lean Six Sigma 6 Ms 6 Ws 7 QC Tools * Histograms, Cause and Effect Diagram, Check Sheets, Pareto Diagrams, Graphs Control Charts, Scatter Diagrams 8 Wastes in Lean (Tim Woods) SSD Global 3 Ps (Always Keep These In Mind) People: Satisfaction Of Both Internal And External Customer. Product: Conforming To The Requirements Specified Process: Continuous Improvement Of All The Operations And Activities Is At The Heart Of TQM. SSD Global 6Ms – Traditional (Another Keep These in Mind) * Machines * Methods * Materials * Measurements * Mother Nature (Environment) * Manpower (People) SSD Global 6Ws WHAT : What will you make/do? WHY : Why will you make/do? WHERE : Where will you make/do? WHO : Who will make/do? WHEN : When will you start/stop this (time scheduling)? WHICH : Which will you make/do this (process, tooling, material sources etc…)? SSD Global 8 Wastes (Lean) T - Transport - Moving people, products & information I - Inventory - Storing parts, pieces, documentation ahead of requirements M - Motion - Bending, turning, reaching, lifting W - Waiting - For parts, information, instructions, equipment O - Over production - Making more than is IMMEDIATELY required O - Over processing - Tighter tolerances or higher grade materials than are necessary D - Defects - Rework, scrap, incorrect documentation S - Skills - Under utilizing capabilities, delegating tasks with inadequate training SSD Global 8 D is Short for Eight Disciplines D#1 - Establish the Team D#2 - Describe the problem. D#3 - Develop an Interim Containment Action D#4 - Define / Verify Root Cause D#5 - Choose / Verify Permanent Corrective Action D#6 - Implement / Validate Permanent Corrective Action D#7 - Prevent Recurrence D#8 - Recognize the Team SSD Global Theory of Constraints Overview Theory of Constraints Management Philosophy Eliyahu Goldratt Book: The Goal 1992, but revised Talks a lot about Win-Win Team Building Empowerment and Delegation In That Way Very Lean Friendly Book: The Theory of Constraints TOC Approach Identify the Constraint Focus on the Constraint Follow it Through (On-going Improvement) Sometimes called Constraint Management Basically the philosophy supports a way of handling constraints Theory of Constraints Thinking Process Gain agreement on the problem Gain agreement on the direction for a solution Gain agreement that the solution solves the problem Agree to overcome any potential negative ramifications Agree to overcome any obstacles to implementation Tools Current Reality Tree Conflict Resolution Diagram Future Reality Tree Prerequisite Tree Transition Tree More Information about TOC Current Reality Tree: Cause-Effect Technique Present/Future Value Stream Map similar to Future Tree TOC Software Most Don’t Look Like Trees but Rather Flowcharts There is a TOC-BOK PREMISE “Every real system, such as a business, must have within it at least one constraint. If this were not the case then the system could produce unlimited amounts of whatever it was striving for, profit in the case of a business.……………….” Types of Constraints THE MARKET CAPACITY RESOURCES SUPPLIERS FINANCE KNOWLEDGE OR COMPETENCE POLICY The Five Steps Step 1: Step 2: Step 3: Step 4: Step 5: Identify the system's constraint(s) Decide how to exploit the system’s constraint(s) Subordinate everything else to the above decision Elevate the system’s constraint(s) If in the previous step, a constraint has been broken go back to step 1, but do not allow inertia to become the system’s constraint Inertia is the resistance of an object to a change in its state of motion Parkinson’s Law “WORK EXPANDS TO FILL THE TIME AVAILABLE” The Softer Side of Lean Six Sigma Professional Skills Attention to History Teams Team Stages Initiating a Team Forming, Storming, Norming, Performing Roles and Responsibilities Training Team Facilitation Techniques Brainstorming Multivoting SSD Global Some Roadblocks to Improvement Conflict Change Lack of Creative Thinking Lack of Critical Thinking Lack of Project Management Knowledge Communication Motivation SSD Global Types of Conflict Resolution Skills Win-Win Collaboration Agreement Empathy Communication SSD Global Same Goes For Negotiation Skills Win-Win Collaboration Agreement Empathy Communication SSD Global