Week 3 - Malts & Brewing Adjuncts

advertisement

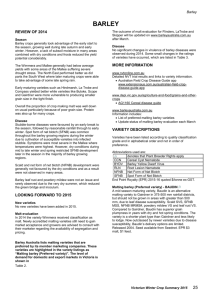

Barley Malt - an overview Most common source of fermentable sugars in beer – Grass family Gramineae – Species Hordeolum vulgare – formed by sprouting barley kernels to a desired length, stripping off the rootlets, and drying to a specific color Barley Malt oveview (continued) Parts of the Kernel – germ (actual growing part of the kernel) Acrospire- above ground portion Rootlet - below ground portion – endosperm (starch food supply for the germ) needs to be converted to sugar for brewing – husk (cellulose protective cover) Types of Barley Two row barley – only two of the six flower rows are fertile and able to produce kernels Six row barley – all six rows are fertile and produce kernels Four row – actually a six row intermediate, not widely used in brewing Differences in barley types Two Row Six Row – bigger kernels, higher – more yield per acre yield per head – lower protein (nitrogen) content – lower husk contents (less grainy flavor) – less enzymes – more diastatic power ie. enzymes (better when using lots of adjuncts) – higher husk level makes for better lautering filter bed 2-Row 2-Row 6-Row 6-Row Purposes for malting 1. 2. 3. Convert the large chains of insoluble starch in the endosperm to short chain water-soluble starches Break down proteins in the barley by activating Proteolytic (“protein breaking”) enzymes Activates the diastatic (“carbohydrate breaking” enzymes that will convert starches to sugars during mashing Malting enzymes (continued) Cytases (hemicellulases & B-gluconsases) – Occur during germination, not malting break down husk cell walls allow the diastatic enzymes to work more easily during the malting process Dextrase – Break the large starch chains at the 1-6 links to make smaller polysaccharide chains Malting Enzymes (continued) Diastatic enzymes – α-amylase breaks the 1-4 links in the middle of the α-glucans starch to make smaller starch chains – β-amylase breaks the smaller starch chains into maltose sugar by breaking 1-4 links near the reducing ends of the smaller chains Glucose molecule Where α-amylase works Maltose molecule Modification Sprouting the grains to correct modification – Acrospire grows from the germ end of the kernel toward the opposite end – Length ratio of acrospire to the kernel determines the level of modification Malting is a three-step process 1)Steeping 2) Germination 3) Drying Primary Immersion Phase Drain & Air Rest Phase Spray or Additional Immersions Steep Out Objective is to obtain uniform germinati on or “chitting” Germination Germination, which began in the steep tank, continues in the compartment where the barley undergoes modification. Control Points In Germination •Kernel Moisture •Piece Temperature •Time Objectives of Kiln Drying •Stop growth and modification •Preserve enzymatic activity •Create shelf stability •Create colors and flavors Milling Weighin g Mashing / Conversion Separatio n/ Boiling Evaporatio n Environmentall y controlled packaging process Bulk Loading/ Unloading Malting Process (continued) Barley steeped in 50-65o F water for two- three days Kernels allowed to germinate between 50-70o F for six to ten days (Acrospire reaches 50% length about day 6) Malt temp raised gradually to 90o F and held there for 24 hrs. (allows enzyme action) Malt temp then gradually raised to 120o F and held there for 12 hours to dry the malt Malt must be bone dry before kilning Modification- a definition The degree of germination a barley kernel achieves during the malting process. – the degree to which the protein/gum matrix of the starch in the kernel is broken down – increases the amount of proteins which will become soluble in water Modification (continued) Modification is achieved through the malting process Varies from under-modified to highly modified malts Modification is affected by – the strain and type of barley used – the malting process itself Differences in Modification Under-modified – more complete set of enzymes – more proteins that will require additional protease enzymatic breakdown to avoid the protein-polyphenol induced haze (“chill haze”) Highly modified – high level of protein degradation – doesn’t require a long protein rest – may not necessarily be suitable brewing all styles of beer Modification: Example 1 Fully modified - Ratio 1.0 – Acrospire as long as the kernel – will have a low protein content – endosperm (starch) almost fully water soluble – Some of the endosperm is lost as it was used by the acrospire to grow to this length. That equates to less potential yield of fermentable sugar Modification: Example 2 75% Modification – Acrospire is 3/4 the length of the kernel – more of the endosperm is retained for fermentation availability – more protein remains (adds complexity to the beer) – the expense is that there is reduced diastatic enzyme activity for mashing >75% Degrees of Modified Malts Continental American 6-row – 50-75% modified – Fully modified – retains more – because of higher endosperm for fermentation – creates more protein complexity but: – at the expense of reduced enzyme activity protein content, has greater enzymatic strength than Continental Degrees of modification (cont.) Both Continental and American malts require a protein rest at about 122o F to degrade albuminous proteins – promotes yeast growth – aids in head retention Degrees of modification (cont.) Caramel & Crystal Chocolate & Patent – fully modified – under modified (<50%) – kilned at 50% moisture – do not require protein (not bone dry) – This essentially mashes the starch directly inside the kernel husk rest, as the kilning process degrades the starches Kilning Kilning is roasting the malt to achieve the proper color and other characters of a particular malt – Raising the temperature of the dried malt to a particular level – Creates flavor and bodybuilding melanoidins from the amino acids and malt sugars in the malt Degree of modification + kilning = type of malt Kilning (continued) Pale Malts (British & American) – Kilned between 130o and 180o F Vienna Malt – low kilned at around 145o F Czech Malts – raised slowly from 120o to 170o F, then roasted at 178o F Kilning (continued) Dortmunder & Munich malts – kilned at low temperature, then raised before the malt has dried to 195-205o F (Dortmunder) or 210-244o F (Munich) Amber malt – well modified, then dried and rapidly heated to 200o F. – Temp then raised to 280-300o F and held until desired color is reached Kilning (continued) Crystal & Caramel – fully modified, then kilned at 50% moisture – Temp raised to 150-170o F and held for 1.5 to 2 hours – Essentially mashes the endosperm inside the husk – Heated to final roasting temp, time/temp determines final Lovibond color index Kilning (continued) Chocolate & Patent Malts – dried to 5% moisture – roasted at 420-450o F for up to two hours – high heat degrades the starch so no protein rest is needed – can also be roasted over beechwood fires (Bamberg style) Kilning (continued) ALL malts – Once the malt is evenly roasted, they are cooled to 100o F – Placed in a rotary bin (or some other method) and rootlets are removed – Malt needs to rest for at least one month before mashing Other Malted Grains Wheat – has enough diastatic power on its own, but not enough husk to effectively lauter on its own – high protein & β-glucan content compared to barley, needs longer protein rest if used in large quantities Rye, Oats, Sorghum - sometimes malted, usually used in raw form Barley Contents Sugars & Starches- converted to sugars during mashing Enzymes - a type of protein, influences protein content of the mash, too! proteins- food for the germinating acrospire Barley Contents (continued) free nitrogenous compounds B-complex vitamins- needed for yeast development Phosphates - necessary for acidification of the mash & used by yeasts Barley contents (continued) Trace Elements – Tannins – cellulose – polyphenols components of the husks can cause harsh flavors in beers if leached out by hot or alkaline sparge water Barley contents (continued) Fatty acids & lipids – support respiration of the embryo during malting – can create oxidative flavors and low head retention if excessive levels carry into the wort Hemicellulose & soluble gums – must be reduced by enzymes to permit head retention, else may cause clarity problems Categories of Specialty Malts •Kiln Produced •Roaster Produced Kiln Dried, Roasted Malts Victory® Special Roast Chocolate Dark Chocolate Black Roasted Barley, Black Barley Cereal Adjuncts Cheap source of carbohydrates with minimal protein addition Must be gelatinized before mashing - preliminary boil or flaking through hot rollers – corn (maize)- heavy use in Amer. light lager – rice grits - heavy use in Amer. light lager – sorghum – flaked barley, rye, and wheat Other Adjuncts Corn sugar Cane sugar – fully fermentable, cheap, produce more EtOH and drier beer – cidery flavors tend to be produced due to the enzymes used by the yeast to metabolize the sucrose Other adjuncts (continued) Honey – common in specialty beers – contributes some aromatics – tends to make beer thinner and more alcoholic due to high sugar content Other adjuncts (continued) Malto-dextrin – syrup or powder – adds body or “mouth feel” to beer Caramel Molasses Maple syrup licorice Color Determined by types of malts used Important characteristic of styles Two scales – EBC (Europe) – SRM (USA) Low (light color) to high (black) Color (continued) Amer. Lite Lager: 2 to 4 SRM Pilsner: 3-5 SRM Oktoberfest: 5-14 SRM Doppelbock: 20-30 SRM Stout: > 50 SRM