Employee Survey Results

advertisement

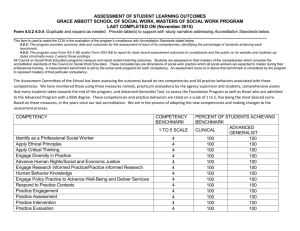

Eisai Production Operations Employee Development Solid Dose 101 Production Operations Employee Development Safety Creating and Transferring Knowledge… Pharma Work GMP …for the manufacturing of products that benefit both patients and their families. Employee Development Model Recruiting Skills/ Training Development Compensation Performance Management Organizational Systems Job Specific Technical Knowledge and Skills Competency Production Operations Specific Integrity Personal Effectiveness Competency Quality (GMP) Respect Core Business Application EHS Foundational Professionalism Required Competency (GMP/EHS) Quality Teamwork Why did we develop this program? Employee Survey Results Meet our Future Business Needs Remain Globally Competitive Project Management Proposal July 19, 2006 Employee Survey Results Rewards of work survey conducted • 85% Response Rate Areas Employees Not Satisfied: Project Management Pay Process Proposal Talent & Performance Management Career Opportunities July 19, 2006 How do we know if we are getting returns on our investments ? • Quality Improvements • Reduced Turnover • Improved Employee Satisfaction • Highly Productive and Knowledgeable Workforce How We Got From…. Now Then Then Why do my co-workers get paid more or the same as me and I have more knowledge and do more? Is there a way to have a more objective method to measure skills, knowledge and performance? What is required to move to the next position? How can we get more training? Program Objectives Employees are paid based on knowledge, skills and performance. Employees know what is expected of them in their current position. Employees know what it takes to move to the next position. Employees have individual development plan. Career Ladder Technicians and Team Leads Team Leads Proficient Mastery 3 3P 3M 2 2P 2M 1 1P 1M Technicians Proficient Mastery 3 3W 3P 3M 2 2W 2P 2M 1 1W 1P Levels Levels Level Progression Working Knowledge 1M Skill Step Progression Groups Included: Manufacturing, Packaging, Mechanics Project Process 3. Competencies Mapped (skills/knowledge defined) 1. Career Ladder Qualification/Assessment Documents Developed Employees Assessed/ Mapped to Level & Pay 2. Data Gather for Task Analysis Job Descriptions (written/evaluation/pay scale) Learning Plan Learning Resources Made Available Data Gather Task Analysis ACTIVITY TASKS/STEPS EQUIP’T / TOOLS/ DOCS KNOWLEDGE / SKILLS / ATTITUDE PERFORMANCE EXPECTATION S PERFORMANCE MEASUREMEN T LEARNING (Knowledg e transfer) Line A Operate Palace Bottle Unscrambl er Turn on/off Main power Start/Stop equipment Correctly identify cases Load bottles into hopper Turn on/off air supply Monitor component flow Reload component s SOP #PK88 GMP’s Line overview Location, purpose of equipment component s Basic equipment operation HMI screens and equipment controls Able to keep equipment operating 100% Able to perform changeovers without assistance, according to SOPs, and within a specified time Able to clean equipment and work areas according to SOPs Line efficiencies as measured by throughput # completed batches Presentation/De moTransfer skills = OJT with use of references (20 hrs. Filler, Labeler; 5 hrs. other units) Reinforce concepts /practice skills = Hands on with trainer feedback and explanation Mapping to the Job Description Major Activities Tasks/Steps Competency Grouping Working Knowledge Proficient Mastery Equipment Operation X X X Clean Equipment X X X Changeover X X X Competencies Write policies and procedures for equipment X (Level 3) Training others on equipment Troubleshooting X) Adjustments requiring physical intervention, I.e., changing codes, adjusting PE’s, etc. Inspection X X X X X X (Level 2 and above) X X X Competencies Competencies Working Knowledge Proficient Mastery Equipment Operation X X X Clean Equipment X X X Changeover X X X Write policies and procedures for equipment X (Level 3) Training others on equipment Troubleshooting X) Adjustments requiring physical intervention, I.e., changing codes, adjusting PE’s, etc. Inspection Performance Levels X X X X X X (Level 2 and above) X X X Mastery (M) Packaging Position Chart Assessments Develop Assessment Skill Assessments Skill Assessment Qualification Process Course Module 1 (ie Cleaning) Module 2 Module 3 Module Delivered (Classroom /Online/ Self Study) Module Delivered (0nline Classroom Self Study Module Delivered (0nline/ Classroom Self Study) Knowledge Check OJT Performance Evaluated Knowledge Check OJT Performance Evaluated Knowledge Check OJT Performance Evaluated Qualified Qualification Pay and Progression System End Results Training Opportunities Levels Competencies Level III 4 lines Same as Level II Competencies In addition to: Training Administration; Presentation Leadership/Mentoring Advanced Troubleshooting (Mechanics Skills) Document Revisions/Writing EHS Certification SAP Investigations Maintain PI Sheets Level II 3 lines Same as Level I Competencies In addition to: Documentation Review SAP MS Word/Excel Perform carry over Pull and Verify Samples Level I 2 lines Line Operations Proper Documentation Practices Training other employees on Equipment Computer (Windows, e-mail, eLLIE (SOP Reading; Online Training) GMP Knowledge Proper Documentation Practices Team Player Communication Line Supply TRAINING PROVIDED Shutdown Training – Public Speaking – On-the-Job Training – Mechanical Skills – Solid Dose Overview – Technical Writing Onsite Training – Microsoft Word, Excel, PowerPoint – Deliberate Documentation Knowledge Space SIMULATION - MANUFACTURING Screen shot to be added COMPUTER BASED COURSES - SAFETY Team Training The right pieces … for Performance Competencies Career Ladder Skills/ Knowledge Training Business Impact • Quality Improvements • Reduced Turnover • Improved Employee Satisfaction • Highly Productive and Knowledgeable Workforce Program Check In Focus Group Feedback Pace Revaluate timing (ie pay increase 3 mos., 6 mos?) Training Limited due to staff Pay Market Analysis Make Lead Pay and Level/Step Info Public Management Response Action: Will not change pace at this time. Program is new; difficult to change without sufficient data. ACTION: Provide additional training options: Micro sampling (environment / water) Instrument calibration Cleaning validation (swab sampling) Options will continue to expand based on business opportunities, (e.g., in-process lab) ACTION: Hire temps to provide opportunity for our full time regular employees to train in other areas. ACTION: Add wage information for Manufacturing, Packaging, Leads and Mechanics to Public Drive ACTION: Annual Survey of Industry Wages Learnings Successes Vice President Support Employees involved at each step “Pull” by employees for training Interest in expanding programs to other areas Challenges Ability to rotate based on business needs Adding additional training modules QUESTIONS