EHS Intervention Final

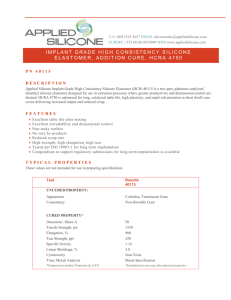

advertisement

Business case for ergonomics interventions Source: Dr. Popov’s Projects Practical Projects Dr. Georgi Popov, QEP Leigh Ann Blunt, Ed.D., ASP John Zey, Ed.D., CIH Anthony Hirner, CSP Silicone Wire Problem Statement • Silicone wire production involves variety of hazardous chemicals, toxic materials, and hazardous waste. • Requires repetitive movements • CTD’s, Lower back injuries, CTS • HR reported difficulties hiring new employees • High turnover rate • High cost of training and re-training Silicone wire Wire Production Process and Materials Step 1 • The first step is to feed the raw silicone into the extruder. Talc powder is applied to the raw silicone to improve the process. Step 2 • The next step is to apply fiberglass tread on the basic silicone wire. Fiberglass tread is applied utilizing special treading machine. Silicone wire extrusion process Ovens PIE Steps 3 - 5 • Third step is to apply another layer of silicone and heat it to 4800F in order to cure it. • The same silicone extruder like in step one is utilized. • Fourth step is to apply another layer of thicker reinforcement layer of fiberglass. • The same fiberglasstreading machine is utilized during this step. • Fifth step is to apply final layer of silicone and print ink. Spark plug boots • The final step is to assemble the ignition wire and install spark plug boots. • The company utilizes spark plug boots made of silicone. Crimping silicone wires • Manual Process Next step • Once the insulation is stripped, it will expose the actual wire that conducts spark to the spark plugs Folding • The workers are folding the wire over back onto the insulated part of the plug wire Crimping • Employees put the end of the wire with the terminal on it into crimping tool. Fitting Spark Plug Boots • Manual operation • Apply milk like lubricant • Test the wire Project Cycle Efficiency Analysis VAT - Work that customer would recognize as necessary to create the product or the service they are about to purchase. TLT - How long the process takes from start to end. FYI: Source: Wire Lean 2007 tab Ergonomics • Repetitive motion is common for spark plug boots installation operations. • Unfortunately, the nature of the work requires a lot of repetitive movements. MSD’s are common. Countermeasures - Admin • The administrative control option • One possible option is to reassign the boots installation workers from the morning shift 7AM – 11AM to the packaging department. • The workers from the packaging department will be cross-trained to install spark plug wire boots in the afternoon. • Cost - $ 1250 training Semi-Automatic Crimping Machine • • • • • • • Initial investment – $17,500 per workstation Engineering cost – $ 4700 per terminal Utilities – $ 500 per year Maintenance – $ 500 per year Training – $ 2500 – 10 workers Improved productivity Employee morale Full Automatic Terminal Crimping Machine • • • • • • • Initial investment – $ 57,500 per workstation Engineering cost – $ 5100 per terminal Utilities – $ 500 per year Maintenance – $ 650 per year Training – $ 2700 – 10 workers Improved productivity Employee morale Financial Analysis FYI: Source: MS Excel Ergo Financial ROI Financial Analysis FYI: Source: MS Excel Ergo Financial: Financial tab Financial Analysis FYI: MS Excel Ergo Financial Compare proposals Results • The management selected Semi-Automatic Crimping Machine (SACM) option • 3 SACM Total $ 70,100 • Admin option was implemented for a short time – insufficient results • Reduced personnel from 90 to 47 (20% reduction due to current economic “difficulties”; 15% personnel reduction due to improved productivity; 12% other). • Production down only 11% from 2008 Project Cycle Efficiency Analysis – Post Intervention FYI: Source: Wire Lean PCM Lean tab EHS INTERVENTION IS NOT AN EXPENSE -IT IS AN INVESTMENT