BRC - ansica.org

advertisement

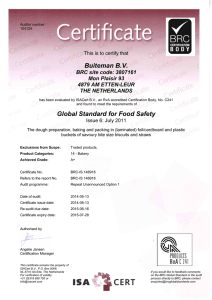

BRC Global Standard for Food Safety March 2010 John Kukoly – BRC Americas John.kukoly@brc.org.uk Heritage of the BRC Standards Before 1996 – Retailer technologists inspect their own suppliers 1998 – Retailers join to create a common standard for food – BRC 2000 – The BRC becomes the first standard approved by the GFSI 2008 – Issue 5 of the BRC Global Standard for Food Safety published What is The Consumer Goods Forum ? 200 retailer companies 200 manufacturer companies 150 countries Paris, HQ Mission: provide a platform for knowledge, leadership and development of common positions and tools for key issues affecting the industry Washington Tokyo Shanghai Singapore The Consumer Goods Forum Board of Directors The Consumer Goods Forum GFSI Global Food Safety Initiative Food safety for producers GSCP Global Social Compliance Program Social accountability for producers GUSI Global Upstream Supply Initiative IT integration (GS1) The Rationale For The Development of Private Sector Schemes to assure product safety to provide brand protection to meet legislative requirements to promote business improvement and efficiency to promote consumer confidence Focus of GFSI Who: Food producers On farm, aquaculture Processors (post harvest impact on food) What: Food Safety GMP’s (GAP’s) HACCP Food Safety Management Systems How: Scheme requirements Rules of engagement and operation Not Included in GFSI x x x x x x Quality systems Social accountability Environmental systems Packaging manufacturing Animal welfare Sustainability Material may be added to schemes outside of GFSI oversight, and may or may not be included in the accreditation. GFSI Status Currently approved • BRC • Dutch HACCP • FSSC 22000 • GlobalGap • Global Red Meat Standard • IFS • SQF 1000, 2000 (level 2, and level 3) www.mygfsi.com BRC Status • In excess of 13,000 sites actively certified around the world. • Surpassed 500 sites in North America in 2009. • Average time to implement BRC and become certified for the first time – 8 months. • Average length of time BRC audit takes on site in North America – 2.5 days. www.brcdirectory.com The BRC Global Standard • Best practice standard for food safety and quality in one standard. • Managed by the BRC but driven by the stakeholders- retailers, manufacturers and packers. • Market leading standard for food manufacturers with over 12,000 Certified sites world wide. • GFSI recognised. Audit Evolution - Inspection based evaluations First party audits Second party audits Third party unaccredited audits Third party accredited scheme based audits Governing Structures Standard Owner Auditor Manufacturer Accredited Certification Process IAF Accreditation body Standard owner BRC Auditors Certification Body Manufacturer Certification Process Obtain Standard Self Assessment – training course optional Select Certification Body www.brcdirectory.com On Site Audit Critical, Major, Minor Non-conformities Identified Correct non-conformities – 28 days Certification Decision Understanding the Task - Establish the team Review and understand the requirements Preliminary assessment Identify and understand the gaps Define realistic timelines, with milestones Establish senior management commitment Go! Laying the Groundwork - Document and record control system Risk assessment platform Formalize training management Initiate and define Senior Management Review Risk Assessment - Define the situation - Define the risk (chemical, biological, physical, allergen) - Categorize the risk (severity, likelihood, historical data; getting input from multiple viewpoints, consequences) - Risk matrix - Control strategies - Outcome potentials Senior Management Review Date: minimum every 6 months, or in the event of a product withdrawal, audit failure, or serious customer complaint. Attending: Senior site management, all department heads. Agenda: 1. Review of previous assigned action items, completion and outstanding. 2. Food safety and quality objectives. a. Customer complaints b. Out of specification production c. Internal audit results d. Environmental test results 3. Performance results. a. External audits and results b. Customer communication and performance indicators c. Product withdrawals, non conforming incidents, allergen incidents d. Process deviations e. HACCP system review f. Scientific changes g. Regulatory or label requirement changes h. Resourcing reports i. Continuous improvement program Assigned actions, with responsibility and timelines: Minutes: To be updated with closure or completion of assigned items. Risk Assessment Risk Assessment: Protective Clothing Risk: Contamination of product with hair, fibres, microorganisms, and other materials. Area / Risk Severity Likelihood History Control Strategy Receiving L L L Hair nets, coats. Not to expose product Raw warehouse M L L Hair nets, coats. Not to expose product Production Finished warehouse Truck drivers H L L H L L M L L Hair nets, long sleeve shirts, pats, shoes, gloves if handling product. Hair nets. Not to expose product. None L Hair nets, coats. Not to touch product or equipment. Visitors Outcome: M L Product is protected from contamination via personnel. Review based on consumer complaints on an annual basis. BRC Standard •Free to view and evaluate the standard •Purchasing copies of the Standard, Implementation Guide and Guidance Documents www.brcglobalstandards.com www.b John Kukoly john.kukoly@brc.org.uk www.brcglobalstandards.com www.brcdirectory.com Food Packaging Consumer Products Storage & Distribution