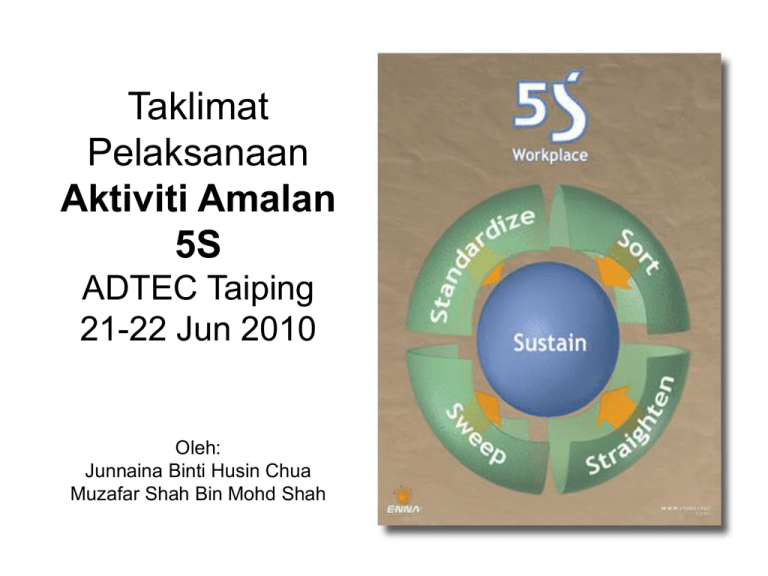

1 SGA - ADTEC Taiping

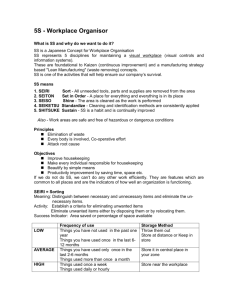

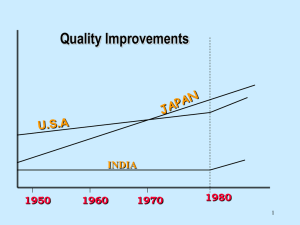

advertisement

Taklimat Pelaksanaan Aktiviti Amalan 5S ADTEC Taiping 21-22 Jun 2010 Oleh: Junnaina Binti Husin Chua Muzafar Shah Bin Mohd Shah JAPANESE ENGLISH BAHASA MELAYU SEIRI SORT SISIH SEITON SET IN ORDER SUSUN SEISOU SHINE SAPU SEIKETSU STANDARDISE SERAGAM SHITSUKE SUSTAINE SENTIASA AMAL ERTI PEMBENTUKAN (ORGANISATION) KEKEMASAN (NEATNESS) BERSIHKAN (CLEANING) PIAWAIAN (STANDARDISATION) DISIPLIN (DISCIPLINE) CONTOH Buang sampah sarap Mendapatkan dokumen dalam masa 30 saat Setiap orang bersihkan tempat kerjanya sendiri Tempat penyimpanan yang jelas dan mudah digunakan Lakukan 5S setiap hari QUALITY EMPLOYABILITY WHERE? TOOLS INDIVIDUAL 1. MS ISO WORKSHOPS 2. KAIZEN WORKPLACE 3. TQM QUALITY EMPLOYABILITY 5S ACTIVITIES MAIN OPERATIONS IMPROVEMENT 1. Working Habits PROBLEM 2. 3. FACILITIES Monitoring Control TRAINING MATERIALS SUPPLY Waste Reduction (Generation, Disposal) Gain Control Improvement (Innovation, Kaizen) Standardize (maintenance, critical parameters, procedures) (equipment, material & Inventories) Wasteful, no add value, unproductive unevenness overburden T I M W O O D S : Transportation : Inventory : Motion : Wait : Over-processing : Over-production : Defect : Searching 5S Systematic Organization WASTE / IMPROVEMENT Reduce Finding Time Reduce Selection Error Reduce Finding Time Sorting Visual Reduce Errors Placement Reduce unnecessary movement Reduce downtime Scrubbing Reduce repairing time Clean Increase equipment knowledge BENEFITS Cost Reduction Improve Quality Faster Increase Productivity Increase Safety & Quality More Space Increase Safety Increase Uptime STEERING COMMITTEE Policy Maker May ~ July 2009 SECRETARIATE July 2009 5S TEAM Facilitator Leader Implementer SUPPORTING TEAM Members Audit Promotion Improvement Training Jan 2010 STAGES DEPTs PILOT TEAM 1st G 2nd G UNITs ADMIN 8 ppl 8 ppl 4 ppl (HOD + Rep) X 4 Depts (PP + Rep) X 4 Units 1 PPT (PA) 3 PAP 1 SGA X 4 1 SGA X 4 Dept Units 3 SGAs X 4 1 SGA X 4 Dept Units 1 SGA 3 SGAs (Pent, Kew, & Asrama) JPA 1 Rep 1 SGA 1 SGA Team Bhg. Tek. Mekatronik Location Workshop 1 Schedule ACTIVITY NO. of DAYS SCHEDULE Check List Preparation 2 9~10 Feb Floor Plan 5 11~19 Feb Material Identification 4 22~25 Feb Work Determination 5 1~5 Mac Preliminary 1) 2) 3) 4) 5) 6) Preliminary Seiri Seiton Seisou Seiketsu Shitsuke Target Area Define Workplace Layout/floor plan Purpose and Functions Main Activities Key persons Materials required Evidences Photos Data Target (objectives) Display Board 1. Separate items by categories a) Stock b) Facilities c) Location d) Documents e) Machines f) Fittings g) Stationeries h) Others 2. Do it with colleague, look for a) Wanted vs. Unwanted b) Needed vs. Not Needed c) Doubt move it out 3. Perform Visual Control a) Policies Steering Committee b) Categories easy to relocate Is this item needed? Tagging Unneeded Needed Unknown usage ▪ in what quantity? ▪ how frequent it been used? ▪ Where should it be located? Unwanted Excessive Defective items Dead Stock Not needed Sleeping Stock ▪ How should it be disposed? ▪ Where to disposed? (Holding Leftovers Materials area –Gemba, Dept, Institute) ▪ When to disposed? Evaluation Seiri audit checklist S1: Seiri=Sort (Clear up) 1. Are there any tools, spare parts, materials left on the floor, nearby equipment? 2. Are all frequently used objects sorted, arranged, stored and labeled? 3. Are all measurement instruments/devices sorted, arranged, stored and labeled? 4. Does the inventory or in-process inventory include any unneeded materials or parts? 5. Are there any unused machines or other equipment around? 6. Are there any unused jigs, tools, dies or similar items around? 7. Is it obvious which items have been marked as unnecessary? 8. Has establishing the 5S’s left behind any useless standards? Rate Visual Layout Look around with colleague Decide the most effective working flow by frequency ▪ Hourly/Daily ▪ Weekly ▪ Monthly/Yearly Labeling Divide the workplace into sections ▪ Frequency of usage ▪ ▪ ▪ ▪ Hourly Daily Weekly Monthly ▪ Type of item ▪ In use ▪ Stock Layout Draw workplace layout ▪ Machine’s location ▪ PIC ▪ Pictures 4W1H 30 sec detection Inform everyone Lines Equipment Supplies Common Areas Safety Zones Lines (cont’) Divider Outlines Arrow Direction, rotation Limit (max/min height, weight, qty) Label Colour Coding Item Location Signs Equipment related information (SOP) Showing location, type, qty PLAN Root Cause Improvement Kaizen DO What to clean Who in-charge Cleaning method ACTION Cleaning Schedule Cleaning Tools CHECK Reoccurrence (dirt/dust) Cleaning Major Cleaning Day (overall) Daily Routine (10-15 mins) Weekly/Monthly (specific area) Checking (4W1H + cause n effect) Prevent reoccurrence Preventive Maintenance Cleaning Schedule Owner Log Improvement (Progress chart) Plan Activities chart Responsibilities Establish guideline (team, visual) Develop standards Objective Team maintain adherence to the standard How? 5S Training Communication Board Evidence Visual Standard and procedures Daily 5 min activities Weekly 5S application