Safety and Standards Year 10 THEORY 12MAY

advertisement

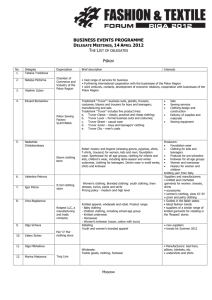

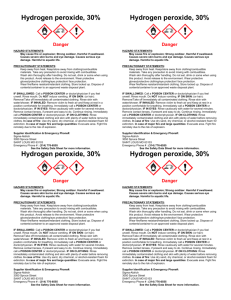

Safety and Standards Year 10 Revision Lesson QUALITY ASSURANCE AND QUALITY CONTROL IDENTIFYING QUALITY CONTROL CHECKS Q.A. means GUARANTEE OF QUALITY. Companies assure customers that a product is fit for purpose and HIGH QUALITY. Documents are produced showing the systems used to ensure that quality is maintained. IMPLEMENTING these is the responsibility of EVERYONE working in the business. This is called TOTAL QUALITY MANAGEMENT. Q.C. is carried out during manufacture, to check: YOU AS DESIGNERS MUST FREQUENTLY CHECK THE QUALITY OF YOUR PRODUCT: •Are seams secure? As its being designed •Are there missing stitches? During manufacture •Are seams puckered or uneven? At the end of manufacture •Are pockets and zips stitched correctly? SIZE, APPEARANCE, FORM, COLOUR, FLAMMABILITY AND PERFORMANCE. Your specifications should contain details of when and how each QC check needs to be carried out. The best time to identify what QC checks are needed is when you are modelling. At this point you should have a list of questions, eg: •Is there needle damage? •Are components secured? EVALUATING DESIGNS REGULATIONS You should find out if the target market likes your ideas. You could do this by showing sketches or fabric samples, then get some FEEDBACK. THESE ARE PUT IN PLACE TO LOOK AFTER CONSUMER INTERESTS. TO ENSURE THAT PRODUCTS ARE OF A GOOD QUALITY AND SAFE TO USE. At this stage, you could also carry out tests to find suitable materials. However, only carry out tests if: Regulations are put in place by… They will help you make decisions about the end product, i.e. if they are relevant. MANUFACTURING GROUPS-to provide a code of practice for their members. It is a FAIR TEST, i.e. various fabrics tested in exactly the same way under the same conditions.e.g. The Government, through ACTS OF PARLIAMENT. DON’T WASTE TIME! TECHNICAL TESTS TECHNICAL TESTS STANDARDS LEGISLATION A STANDARD is an agreed specification that sets out PRECISE CRITERIA to ensure the reliability and quality of a product or service. Below are several examples of regulations that are applied to children’s textile products: Standards are regulated by the BRITISH STANDARDS INSTITUTION (BSI). In Europe this is done by the EUROPEAN COMMITTEE FOR STANDARDISATION. Standards are voluntary. However, some laws and regulations refer to certain standards making them compulsory. •Nightwear Safety Regulations, 1985. •Nightwear Safety (Amendment) Regulations, 1987. •Children’s Clothing Regulations, 1994. •The toy safety Regulations, 1995. (includes some clothing items, e.g. Bunny Slippers). •Food Imitation Regulations, 1989 (e.g. buttons must not resemble food). •Code of Practice for the Design and Manufacture of Children’s Clothing to Promote Mechanical Safety BS7907, 1997. •Children’s Clothing (Hood Cord) Regulations, 1976. SAFETY STANDARDS Textile products, and the components in them, have to achieve certain SAFETY STANDARDS before they can be sold to the public. This means they MUST pass a set of RIGOROUS TESTS. For example, under the BS 5867-1:2004 Specification for fabrics for curtains and drapes, fabrics must pass specific tests for… Washing, colour fastness (whether they fade), dry cleaning, flammability, dimensional stability (if they change length or width, during normal use, washing or cleaning) and wear and tear. Textiles must also conform to certain labelling requirements. Manufacturers who meet BSI standards are awarded a KITEMARK. The BSI KITEMARK shows the consumers that a product has been tested against nationally recognised standards. The kitemark scheme is an independent and ongoing assessment process, that ensures standards are achieved and maintained. The CONFORMITE EUROPEENNE ‘CE’ SYMBOL is the manufacturer’s self-declaration that the product MEETS THE MINIMUM REQUIREMENTS from the EU directive to be allowed to be sold. SAFETY OF CHILDREN’S PRODUCTS PRODUCTS FOR CHILDREN have many factors that need to be considered, including the following: SAFETY OF OTHER PRODUCTS Any product must be safe and easy for the TARGET MARKET to use. Below are some examples of health and safety considerations: They must not contain materials that could melt or catch fire. Does the product need to withstand extreme temperatures-oven gloves, skiing clothing? They must not have any parts or components that could come loose and choke or harm a child. Does the product need to provide protection from certain elements-tents, UV protective clothing? Dyes, paints and inks must not contain harmful substances or allergens. Are there any specific user requirements-if your product is for the elderly, are fastenings easy for arthritic hands? Fastenings must be safe and easy to use. Is the fabric strong/durable enough for its purpose-does the product need to hold anything with sharp edges, will it be used for carrying? HEALTH AND SAFETY IN THE WORKPLACE HEALTH AND SAFETY IN THE CLASSROOM In industry, a Health and Safety Officer usually carries out a risk assessment and then follows these procedures: SAFETY PROCEDURES are controlled by Government Safety Laws, European Safety Laws, or other codes of practice such as: Creates a safety manual Health and Safety at Work Act, 1974 Installs safety signs at key points, next to equipment Creates a code of practice for all users of equipment Outlines what safety wear needs to be used Ensures that new and existing employees are fully trained on the equipment they will be using Workplace (Health, Safety and Welfare) Regulations, 1992 The CONTROL OF SUBSTANCES HAZARDOUS TO HEALTH (COSHH) Regulations, 2002, protect employees from the hazards of substances used in the work place through risk assessment. HEALTH AND SAFETY IN THE CLASSROOM Safety is very important in the classroom. There should be SAFETY GUIDELINES that you will need to follow when using materials, components and equipment. A RISK ASSESSMENT must always be carried out before making a product. That means… Identifying the equipment and processes that are needed Highlighting which equipment and processes are POTENTIALLY HAZARDOUS Putting a plan in place to remove or reduce each risk, including… - SAFETY PROCEDURES for using equipment - PROTECTIVE CLOTHING requirements Examples of Safety Signs... P O T E N T I A L H A Z A R D S