AirRockets - Ideas

advertisement

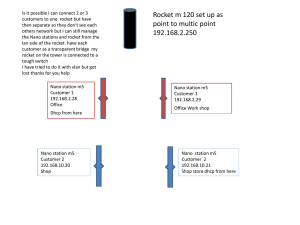

By Bill Kuhl http://www.scienceguy.org How it Works An air-powered rocket is a rocket propelled upward by a blast of air. No propulsion comes from the rocket as in a solid fuel rocket or water rocket. Air is forced into a chamber that is a tube that the rocket slides over. The pressure of the gas which is air, becomes much higher but the volume is the same in the chamber. This forces the rocket upward. The blast of air comes from another chamber that is quickly compressed by stepping on it with your foot or feet. The inspiration of the idea to build this project came from a rocket I purchased at a hobby shop. Building My First Rocket I looked at the store-bought rocket and tried to think of materials that I could use to build a rocket that was safe, light, and cheap. Foam pipe insulation would fit over 1/2” PVC pipe, would be relatively light and absorb shock. A ping pong ball cut in half would fit over the insulation, this would be light, strong and not pointed. Cardboard could be for the fins and easily trimmed with a scissors to experiment with different areas. Packing tape covered the rocket for stiffness and to make it easier to attach the fins. About the Construction This project is so simple that I really do not think detailed construction plans and article are needed. I would rather share ideas of how I approached the project, some concerns, and where to find materials needed. The educational value of this project would also be greater if more creativity were used in the construction. What Are the Basics? Only a launcher and rockets are needed. The launcher consists of a base to hold a tube vertical that the rocket will slide on during the launch. I created a simple X-shape base structure from strips of lumber. The PVC pipe was fastened to the base structure with a cable tie that went around two wooden dowels that went partially into the X-structure through holes drilled in the wood. An “air bladder” is connected to PVC pipe with clear plastic tubing. The air bladder is the portion of the project that I spent considerable time experimenting with. Safety Concerns •The rocket leaves the launcher at a high velocity so it is important that no one is hit with a rocket. •There should be nothing sharp on the nose of the rocket. •The rockets are light in weight thus relatively low in kinetic energy, but getting hit in the eye with anything is dangerous. •Stomping on the air bladder with one foot should be relatively safe but jumping on the air bladder with both feet there is a danger of stumbling or spraining an ankle. Building a Launcher The base for the launcher was built from some cheap lumber that was leftover from home repair project. PVC pipe is relatively inexpensive and found at a lumber or hardware store. I just pressed the pieces together but you could certainly cement the pipes and elbow together. Holes were drilled through the base and then dowels were glued into the base. Plastic tie wraps held down the PVC pipe. This is Prototype #1 with 2-liter bottle for air chamber and a rocket made from foam pipe insulation, a ping pong ball, and cardboard. The 2-liter soda bottle was badly crushed after just a few launches. I am examining the crushed bottle, what is needed is an air chamber that has “elasticity”. That is the physical property of a material to return to its original shape after the external force that made it deform is removed. The external force in this case is my feet jumping down on the air chamber. Prototype air chamber #2 made from heavy plastic shipping bag, foam rubber and tape. A couple of jumps on the bag blew out one side. A science teacher friend had suggested a boat fender might work well for the air chamber, and he was right. Cost was the only issue if everyone in a group is building a launcher. On sale this fender cost $6, normally it was close to $10. I noticed the word “vinyl” on the label referring to the plastic the fender was made of. This prompted me to do further research into this material that worked so well for this application. The new air bladder is in place, it worked well but I kept wishing to increase the altitude of the rocket. My approach to that was to trying to change the air bladder hoping for greater altitude on the rocket. I tried a larger boat fender hoping for more altitude. It would be my estimation that altitude might be only slightly higher, the smaller unit appears to be a better value. How I Attached the Tubing At the spot where there is a small valve is where I drill a hole for the tubing. Plastic fitting is used to attach clear plastic tubing. I used a hole saw drill bit to drill ¾” hole. Hole saw bits have a round steel cylinder with saw teeth that are used for cutting holes larger than drill bits that would normally fit in a drill. I wrapped the plastic insert with tape for a tighter fit and then used hot glue to seal up the hole. The clear plastic tubing needed a little stretching to slip on to the plastic insert. On the larger boat fender I used a longer length of the plastic tubing which is a good idea to get the launcher further away when launching. More About Vinyl and Elasticity The vinyl boat fender had good properties of elasticity. This means it has the property to restore to its original shape after distortion. In this case it is from stepping down on the fender with a foot that does the distortion. Vinyl can be formed to be flexible or rigid depending on the ingredients mixed with the vinyl resin. The vinyl record pictured below is very rigid. Suggested Activity: to learn more about elasticity research Hooke’s Law. Experimenting With Different Air Bladders I was hoping to build a cheaper launcher so I attempted to build the “air chamber”. This worked for a time but after repeated jumping on the chamber leaks would develop. This is how I built an air chamber using foam rubber, heavy plastic, tape, and cloth. The cloth was to keep the plastic from ripping open. Combining materials is the basis for composite construction. Plastic was sealed together with duct tape, multiple layers of plastic might have been more effective to sealing all leaks. Cloth kept the plastic from ripping open, even when jumping on the air chamber but there were still small air leaks detected. I taped a board to the top of the bladder thinking it would more completely press down on the air chamber. Completed air chamber connected to the launcher. Another Approach to the Air Bladder I tried a plunger that used a “bellows” chamber which was not enough pressure when holding it with one hand and pressing down with the other hand. This got me thinking about how the bottom section could be held and then you could push down with two hands using upper body strength. Wastebasket with holes drilled for bottom of the plunger and an outlet for clear tubing made a good base. Pushing down on the top of the plunger with two hands gave a launch of good height but not wonderful height. I replaced the half ping pong ball with half a foam ball that I found in a sporting goods store. The ping pong ball was starting to crack after hitting hard surfaces many times. The plastic would be fine if you only launched over grass. New Approach to Building the Rocket – Paper Rockets A few of the first paper rockets I constructed. New Approach I decided to take a new approach to increasing the launch height and change the rocket instead of the launcher. From heavy paper I created a rocket by wrapping the paper around the launcher tube and taping. Paper fins were taped to the bottom of the rocket. The nose of the rocket was created by slitting the paper tube and putting more masking tape on the top of the tube. I took it outside for some quick tests and it was obvious that the launch height was much greater than the foam rocket. This rocket weighs only half as much and is much thinner also. After launching repeatedly the paper rocket over a hard surface, the paper tube was showing signs of buckling. Paper Rocket left 7 grams foam rocket 13 grams. Color card stock paper held the round shape where it goes onto the launch tube. Newspaper and magazine paper started to shift. Launching the Rocket Launching the rocket is so simple. First make sure the air bladder has expanded back, then place the rocket over the launch tube. Normally the boat fender air bladder comes back to shape rather quickly, but if it is still partially deflated when the rocket is placed over the PVC tube, the altitude will be much less. It is safer for the person launching and easier on the rockets to launch from a softer surface such as grass. Stepping down on the air bladder with just one foot is safer then jumping down with both feet as there is a chance of slipping on the air bladder. The flight path of the rocket will normally be an arc. The highest point in the flight is known as the “apogee”. This is the paper I used, it will be found with office supplies. Building the Rocket Body Tube Half sheet of bond paper is wrapped around ½” PVC pipe. Wrap the paper carefully as it is rather stiff and tends to wrinkle. Keep working the paper tightly around the tube. The bond paper tends to wrinkle in places, so it helps to rub the paper as it rolls around the tube. It will be easier to tape the rolled tube with sections of tape instead of one long piece of tape. Completed paper tube. Fins at the bottom of the rocket help give the rocket stability, that is keep it moving in a straight path. A straight flight path is more efficient and the rocket will achieve a higher altitude. Fins can be made from the card stock paper, tabs are bent in the paper and the fins are taped to the body tube. Most of the rockets I have constructed utilized three fins spaced evenly around the body tube. I did build one rocket with only two fins that did appear slightly less stable during launch . For an experiment I launched one rocket with no fins, it did not get very high and tumbled to the ground. I draw one pattern for a fin on card stock paper with extra material for support tabs. After cutting out the first fin, I trace around it for the other fins, normally I use three fins. Use a straight edge to create the fold in the paper for the tabs. Work the paper over until you have a nice 90 degree bend. Cut slits in the section of paper that was bent up. Bend half the tabs to the other side. Looking straight down at the fin it should look like this. I apply the tape to the tabs and then place everything on the body tube at once, maybe another method will work better for you. Press the tabs and tape to the body tube making sure the fin is pointing straight and that the fins are spaced evenly around the body tube. This was an experiment in using only two fins instead of three. Launching a rocket with no fins tumbles on the way down. The rocket does not get very high either due to unstable flight path. Without a shocking absorbing nose, the rocket tube will begin to buckle when it hits a hard surface. Parts used to make “shock-absorbing” nose. Plastic from a bag is crumpled up for the padding and two layers of the same plastic cover it to make a dome shape. Cover the top end of the body tube with tape to keep the padding from being pushed down farther into the body tube. With the two layers of the plastic stacked together, press the plastic wad into the center. Work the plastic wad and the plastic covering on top of the tape ledge so that it make a nice dome shape. Then tape the plastic covering to the body tube. The Nose of the Rocket The finished nose should look like this. Completed rocket ready for launch. With only single layer of plastic, nose came apart. Space Shuttle I tried to make a rocket that looked like a space shuttle using white paper and foam plate material. The space shuttle on the launch pad. The altitude obtained was pretty good but not as high as lighter rockets with less drag. Space Shuttle coming down at steep angle, it never really glided on the return trip. Find ScienceGuyOrg on Facebook and Twitter