Understanding the Current Condition or Process

advertisement

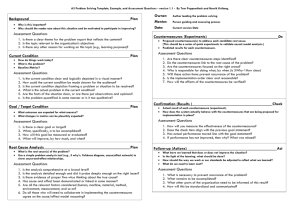

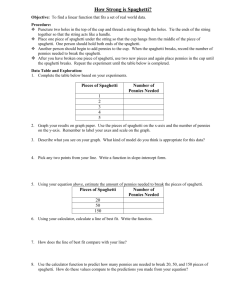

Understanding the Current Condition Process Maps (Flow charts) Making Observations 8 Wastes A3 Roadmap for Performance Improvement at Penn Medicine D F E F I N E I N D Problem Statement (from patient’s/customer’s viewpoint): (10 points) Concise. Customer- focused. Addresses the business case. Shows why a change is needed. Background Provides background for the problem statement (1-3 paragraphs with a minimum of 3 references using APA reference format. Why is this problem important? Who is interested in it (nationally and/or locally) and why? Is there evidence behind this being a problem in healthcare? If so, provide a summary of that evidence. [note: this item will be handed in typewritten, attached to your paper A3] Target Condition: (10 points) Your target condition will move you towards delivering exactly what the customer wants, closer to IDEAL. You identify at least one process, outcome, and balancing measure for your proposed project. You have a clear aim statement, and your process and outcome metrics are expressed as S.M.A.R.T. goals. P I L A N M P R O V E Propose and Test Countermeasures: (10 points) Each countermeasure is clearly related to a root cause in the previous section. For each countermeasure, state how you will DO the tests - What, When and by Whom. A N D D O M O E A S U R E R G A N I Z E C Current Condition: (20 points) There is evidence that you did your “Go and See”. The section is rich with data. Data is presented graphically – bar charts, run charts, or SPC charts are preferred. You have at least one process map (Value-stream, flow chart, spaghetti diagram). The metric(s) you are trying to move are clearly identified. Baseline/pre-test metrics are presented here. Must consider at least one potential process, outcome, and balancing metric You have completed a stakeholder analysis and attached it to your paper A3. L A R I F Y A U N A L Y Z E N D E R S T A N D Metrics/Results: (10 points) Root Cause Analysis: (20 points) If a test of change has been implemented, the S.M.A.R.T. goals are restated and results presented as data. Data should be in a run chart or a statistical process control chart (note: this is not required for successful completion of the project for class; some students may not have this item completed yet; see next bullet) If a test of change has not been implemented, describe which countermeasure you have chosen to test first and why. Reflect on What You Have Done and Learned so Far in Improvement work: (10 points) Write a 1-3 paragraph reflection on what you learned by going through this process. What was most challenging and why? What surprised you most and why? What do you think is your biggest challenge going forward? [note: this will be handed in typewritten attached to your A3] Make it Standard Work (Implement Successful Countermeasures): C C H E C K or S T U D Y A C You use a relevant root cause tool. (5 Whys, Fishbone, Pareto). Must use at least one tool, though you may need more than one for a deep analysis. Your choice of which root cause(s) to tackle is supported by the data in the Current Condition section – i.e. the data validates that you have identified the true root cause(s) and have chosen the right one(s) to work on first. T While this step is not required for this class, be aware that failing to execute this step is extremely common in healthcare. Skipping this step is usually the root cause for failing to sustain improvements after attention has moved on to the next project. You should think about how you might implement a successful countermeasure and sustain any improvements. S E L E C T Executive Sponsor Initial Approval (signature and date): Executive Sponsor Final Approval (signature and date): Not required for this class – but never do a real project without this! Not required for this class – but never do a real project without this! O N T R O L What Adds Value? Value Added: 1. 2. 3. It changes the form, fit or function It is done right the first time The customer would pay for it – more of it is better Non-Value Added (Waste): 1. Any activity that does not meet the value criteria above: a) Unavoidable waste- necessary in the process due to regulatory or supporting value. These activities should be simplified, reduced, or combined whenever possible. b) Avoidable waste - activity that is not value or enabling should be completely eliminated! The 8 Wastes D O W N T I M E • • • • • • • • Defects Over Production Waiting kNowledge wasted - confusion Transportation Inventory Motion Excess Processing Eight Wastes: Healthcare Examples Defects Example: •Lab tests are performed twice because of errors •An x-ray is read incorrectly •Wrong site surgery Overproduction Example: •Making more IV bags than are needed. •Preparing 4 units of blood “just in case” for the OR Unnecessary Transportation Waiting Time Example: •Delayed Cases waiting for instruments Wasted Motion kNowledge Example: •A resident’s bright idea is “lost”, or the resident is confused about how to do a task Extra Processing Inventory Example: •Patient gets wheeled back and forth between the floor and radiology for multiple tests instead of taking one trip for all of them Example: •Medicines held over the shelf-life because of excess ordering Example: •Pharmacy tech walks back and forth looking in multiple places for a particular med Example: •Nurse records respiratory rate in multiple places in the chart •Multiple copies of the same pathology report – in EPIC, in Medview, in SCM, on paper Process Mapping • Purpose – Visually document a process – Understand the existing process and problems – Quickly identify improvement opportunities within the process – Helps communicate inside and outside the organization • Key Principles – – – – Documentation is not substitute for observation A flowchart is a means not an end Your scope defines the boundaries of your map Involve a cross-representation of those who work in the process to create the map – Process maps are meant to be used as working documents Which Process Map is For You? Process Map High Level Process Map Detailed Process Map Description •View from 30,000 Feet •Depicts major elements and their interactions •5-8 steps total •Early in the project to identify boundaries and scope •A detailed version of the High Level Process Map •Fills in the all the steps within the high level steps •To see a detailed process in a simple view •Helps to identify and follow decision points Process snapshot that captures information that is critical to a project •To come to agreement on project boundaries and scope •To verify that process inputs match the outputs of the process •Quality issue •Captures all key flows (of work, information, materials) in a process and important process metrics •Requires a current and future state to be done •To identify and quantify waste •Helps visualize the improvement opportunities •Flow or time issue Emphasizes the “who” in “who does what” •To study handoffs between people and/or work groups in a process •Especially useful with administrative (service) processes Depicts the physical flow of work or material in a process •To improve the physical layout of a workspace (unit, office, floor) SIPOC VSM (Value Stream Map) Swim Lane Flowchart Spaghetti Map When to Use High Level Process Map • • • View from 30,000 feet Used early in the project to identify boundaries and scope 5 – 8 steps total Assess pump/ module need Order pump/ modules Pump/module released Pump/module delivery Pump/module pick-up Recycled Utilization Tool: Spaghetti Diagramming • Reveals waste: Motion Transport Over-processing kNowledge Low Fidelity Spaghetti Diagram Glass wear storage Glass wear storage Lab Tech’s Workstat ion Lab Machine Room Versions of a Process Map Any Process Has At Least Three Versions What You Think It is . . . Verify What It Actually is . . . What You Would Like it to Be . . . The struggle is that this is where everyone wants to start. How to Go and See • NEVER accept opinion • ALWAYS walk the process • ALWAYS walk the process multiple times Guidelines for Observation • Agree on a starting point for observation, for example patient enters a department. • Make sure you introduce yourself to the customer and inform them of what it is you are doing and why. • Try to talk to patients and/or staff when they are waiting, to avoid prolonging the time it takes to complete an operation. • You may need to observe staff AND products/patients separately. – Product/patient observation - stay with the product/patient and record what the product/patient is going through. If the product/patient waits, you wait. – Staff observation – stay with your staff member continuously. • Not too much detail – just enough. • Always do multiple observation sessions. • Observers should summarize lessons learned and present them to the whole team. Discuss the results.