Benefits of Training Stakeholders Acroos the Grain Value Chain

advertisement

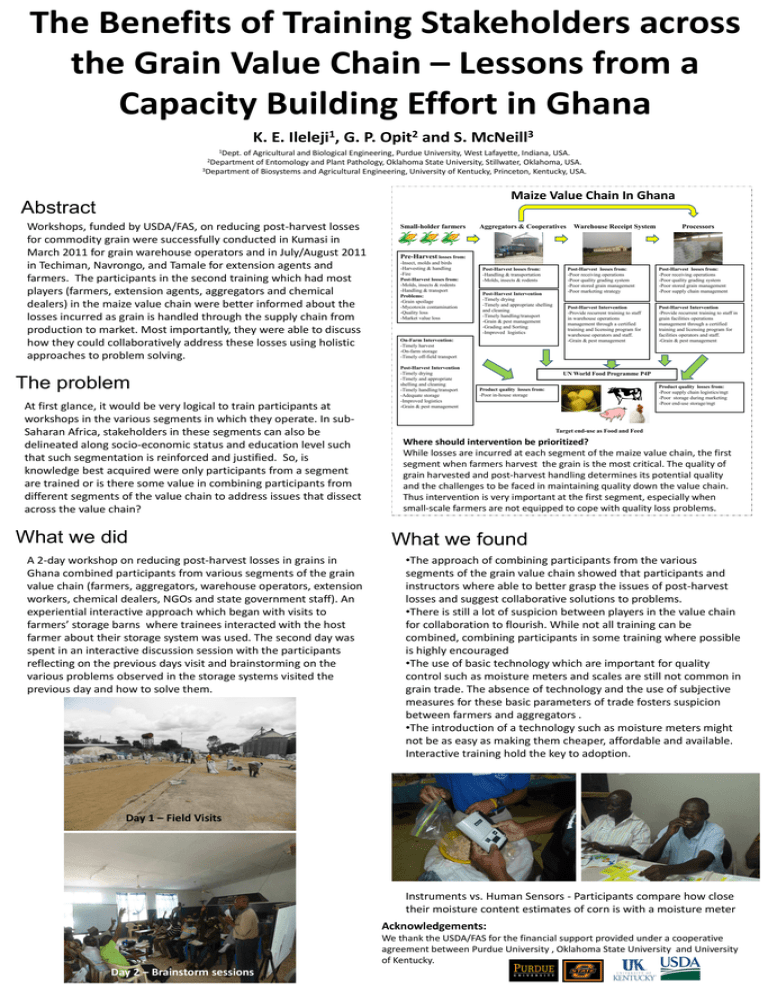

The Benefits of Training Stakeholders across the Grain Value Chain – Lessons from a Capacity Building Effort in Ghana K. E. Ileleji1, G. P. Opit2 and S. McNeill3 1Dept. of Agricultural and Biological Engineering, Purdue University, West Lafayette, Indiana, USA. 2Department of Entomology and Plant Pathology, Oklahoma State University, Stillwater, Oklahoma, USA. 3Department of Biosystems and Agricultural Engineering, University of Kentucky, Princeton, Kentucky, USA. Maize Value Chain In Ghana Abstract Workshops, funded by USDA/FAS, on reducing post-harvest losses for commodity grain were successfully conducted in Kumasi in March 2011 for grain warehouse operators and in July/August 2011 in Techiman, Navrongo, and Tamale for extension agents and farmers. The participants in the second training which had most players (farmers, extension agents, aggregators and chemical dealers) in the maize value chain were better informed about the losses incurred as grain is handled through the supply chain from production to market. Most importantly, they were able to discuss how they could collaboratively address these losses using holistic approaches to problem solving. The problem At first glance, it would be very logical to train participants at workshops in the various segments in which they operate. In subSaharan Africa, stakeholders in these segments can also be delineated along socio-economic status and education level such that such segmentation is reinforced and justified. So, is knowledge best acquired were only participants from a segment are trained or is there some value in combining participants from different segments of the value chain to address issues that dissect across the value chain? What we did A 2-day workshop on reducing post-harvest losses in grains in Ghana combined participants from various segments of the grain value chain (farmers, aggregators, warehouse operators, extension workers, chemical dealers, NGOs and state government staff). An experiential interactive approach which began with visits to farmers’ storage barns where trainees interacted with the host farmer about their storage system was used. The second day was spent in an interactive discussion session with the participants reflecting on the previous days visit and brainstorming on the various problems observed in the storage systems visited the previous day and how to solve them. Small-holder farmers Aggregators & Cooperatives Warehouse Receipt System Processors Pre-Harvest losses from: -Insect, molds and birds -Harvesting & handling -Fire Post-Harvest losses from: -Molds, insects & rodents -Handling & transport Problems: -Grain spoilage -Mycotoxin contamination -Quality loss -Market value loss Post-Harvest losses from: -Handling & transportation -Molds, insects & rodents Post-Harvest Intervention -Timely drying -Timely and appropriate shelling and cleaning -Timely handling/transport -Grain & pest management -Grading and Sorting -Improved logistics On-Farm Intervention: -Timely harvest -On-farm storage -Timely off-field transport Post-Harvest Intervention -Timely drying -Timely and appropriate shelling and cleaning -Timely handling/transport -Adequate storage -Improved logistics -Grain & pest management Post-Harvest losses from: -Poor receiving operations -Poor quality grading system -Poor stored grain management -Poor marketing strategy Post-Harvest losses from: -Poor receiving operations -Poor quality grading system -Poor stored grain management -Poor supply chain management Post-Harvest Intervention -Provide recurrent training to staff in warehouse operations management through a certified training and licensing program for warehouse operators and staff. -Grain & pest management Post-Harvest Intervention -Provide recurrent training to staff in grain facilities operations management through a certified training and licensing program for facilities operators and staff. -Grain & pest management UN World Food Programme P4P Product quality losses from: -Poor supply chain logistics/mgt -Poor storage during marketing -Poor end-use storage/mgt Product quality losses from: -Poor in-house storage Target end-use as Food and Feed Where should intervention be prioritized? While losses are incurred at each segment of the maize value chain, the first segment when farmers harvest the grain is the most critical. The quality of grain harvested and post-harvest handling determines its potential quality and the challenges to be faced in maintaining quality down the value chain. Thus intervention is very important at the first segment, especially when small-scale farmers are not equipped to cope with quality loss problems. What we found •The approach of combining participants from the various segments of the grain value chain showed that participants and instructors where able to better grasp the issues of post-harvest losses and suggest collaborative solutions to problems. •There is still a lot of suspicion between players in the value chain for collaboration to flourish. While not all training can be combined, combining participants in some training where possible is highly encouraged •The use of basic technology which are important for quality control such as moisture meters and scales are still not common in grain trade. The absence of technology and the use of subjective measures for these basic parameters of trade fosters suspicion between farmers and aggregators . •The introduction of a technology such as moisture meters might not be as easy as making them cheaper, affordable and available. Interactive training hold the key to adoption. Day 1 – Field Visits Instruments vs. Human Sensors - Participants compare how close their moisture content estimates of corn is with a moisture meter Acknowledgements: We thank the USDA/FAS for the financial support provided under a cooperative agreement between Purdue University , Oklahoma State University and University of Kentucky. Day 2 – Brainstorm sessions