Eastman Supplier Excelence Program

advertisement

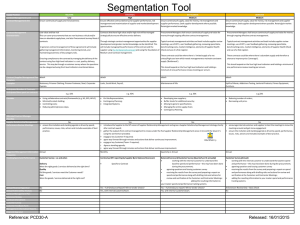

Eastman Supplier Excellence Program January 2011 ESEP - agenda Background Purpose Statement Program Objectives Program Categories • Sustainability Category Benefits Measurement Nomination Process Recognition Q&A What I am reading…. Malcolm Gladwell • The Tipping Point • Blink • Outliers • What the Dog Saw: And Other Adventures Chip and Dan Heath • Made to Stick Question about measuring supplier performance: Why bother? Supplier measurement ‘The Hospital’ ESEP background The program originated in the 1980’s and early 1990’s quality program movement in the US Early quality programs were centered on manufacturing, then moved into the company’s administrative areas • • The quality programs gained momentum and achieved good results (manufacturing, inventory control, etc.) SPC, ISO, JIT and lean manufacturing processes began to expand naturally into purchased raw materials ESEP was originally a ‘downsized’ product from Kodak’s Q1 Program that was used to address the myriad of supplier quality initiatives in the company Interaction and supplier measurement and improvement were also an essential part of the Malcolm Baldrige National Quality Award ESEP purpose statement The Eastman Supplier Excellence Program provides a continuous improvement process by which the highest quality and best value materials, equipment, and services are supplied to Eastman Chemical Company. ESEP program objectives Improve quality and costs Achieve process and product control Develop and recognize suppliers ESEP program objectives ESEP benefits Better understanding of Eastman requirements Improved ratings on quality audits Improved design/specifications/standards Increased customer satisfaction Ongoing business relationships Increased manufacturing efficiency Reduced inspection and testing Coordinated inventory management Better communications Documentation of performance Opportunities to explore new technologies ESEP improvement categories Four supplier recognition categories • Excellence • Innovation • Improvement • Sustainability (added in 2009-2010) Evaluation • Eligibility (key supplier, significant dollar expenditure, etc.) • Performance interval (time frame performance is evaluated) • Criteria • On-time delivery, on-spec delivery, value-adding improvement results, etc. Availability (How often should a supplier be recognized?) Restricted ESEP improvement category - sustainability Sustainability areas of impact are the following: Sustainability The first recipient of this award, Temple-Inland was chosen because of its design innovations to reduce the weight of the corrugated packaging products produced for Eastman’s Acetate Yarn Division, such that we will annually ship 250,000 pounds less packaging materials without adverse effect. Temple-Inland is known for its innovations in sustainability across many operations, including raw material sourcing (over 70% of production is certified under the Sustainable Forestry Initiative), recycling (use of recycled wood fiber in their containerboard operations), and energy management from using wood waste to generate 80% of the energy needed at three of its mills. “We are honored that Eastman has selected Temple-Inland as the recipient of their first sustainability award. This award reaffirms our commitment to be the best by consistently exceeding customer expectations. We look forward to continuing our relationship with Eastman and helping them reach their future sustainability goals.” Steve Sliva General manager of Temple-Inland’s Elizabethton, Tennessee box plant ESEP measurement Objective • On-time performance • Business terms • Non-conformance Subjective • Long term • • relationships Flexibility/responsiven ess Market knowledge This is usually what we run into when we want to measure our suppliers Example: quarterly supplier measurement ESEP nomination process Award nominations are requested in February of each year for the previous year The nominations are reviewed and approved by a management committee Award recognition and plaques are then given to the suppliers as soon as practical Restricted ESEP nomination considerations Eastman is not in business just to give out awards; however, proper recognition does provide long term value from the supplier The award criteria is meant to be a guide; we recognize those suppliers who meet the criteria as well as the intent of the guidelines A supplier does not have to be part of an ESEP team to receive recognition; a “key" supplier can be a function of expenditure level or criticality to the Eastman process If a key supplier meets both the delivery and specification requirements, then develop a list of improvements that can be credited to the supplier such as new contract terms, savings brought by the supplier, improvement projects (tangible or intangible), etc. Additional discussion points Supplier scoring • How do you use it? • What is the difference between a ‘90’ and a ‘70’? Does it matter? Suppliers want feedback; In your opinion, how are they doing? We tend to gravitate toward complexity and make the measurement so difficult that it grinds to a halt Shouldn’t measure suppliers one year and not the next; this is a continuous improvement process Again, we ask the question about measuring supplier performance: Why bother? On a personal level, are you concerned about quality? Questions