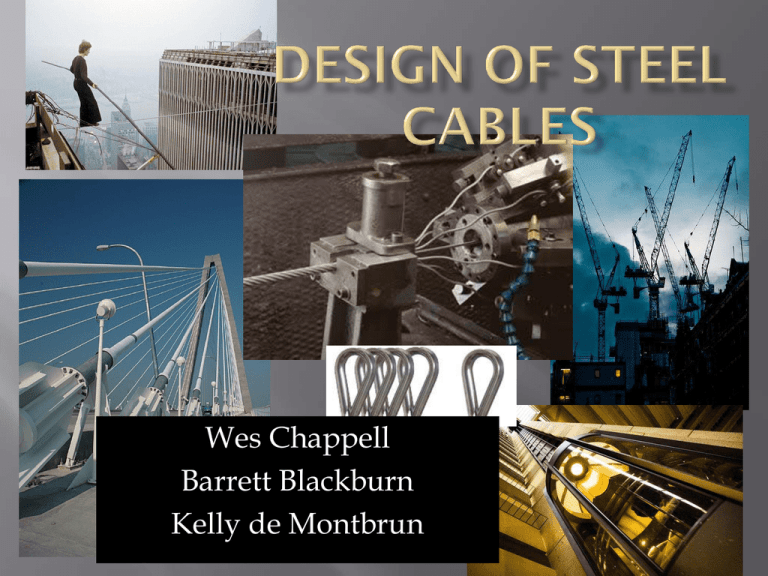

Steel Cable

advertisement

Wes Chappell Barrett Blackburn Kelly de Montbrun as a response to the high failure rate of chain links or solid steel bars used in mining. The use of multiple intertwined strands of wire distribute the load and the friction between the individual wires and strands (because of their twist) further compensates for any flaws. A larger number of wires increases the flexibility of the cable and decreases abrasion resistance. Individual wires are first twisted into a strand, then six strands are twisted around a core which is used to cushion off stress forces when bending the rope. The core can be made from steel or a natural fiber core consisting of hemp, sisal, manila, henequen, or jute and is used to cushion off the stress forces when bending the cable. 3*7 Contains a total of 21 wires; in smaller diameters, it is very flexible. 7*19 Contains 133, allowing for increased flexibility along a range of diameters. 7*7 Contains 49 wires, allowing for abrasion resistance and flexibility through a large range of diameters. 7*49 Contains 343 wires giving this cable extraordinary flexibility. Elevator Wire Rope 8x19 (Seale) Traction Steel with Natural Fiber Core. Rotation Resistant 19x7 Construction (1-6) WC, preformed, extra improved plow steel. Black Powder Coated Galvanized Aircraft Cable Fewer wires=less flexible Very Flexible Flexible Right Hand Lay and Left Hand Lay: Describes the way the strands are laid to form the rope. Ordinary and Lang’s Lay Describe the way the wires are laid to form a strand of the wire rope. On ordinary lay, the outer wires approximately follow the alignment of the rope: with Lang's lay they are cross at an angle of about 45°. Alternate Lay Lay alternates between Ordinary and Lang’s Lays Left-Hand, Ordinary Lay Completed Cable Core Strand Lang's laid rope is able to flex over sheaves more easily (with less damage) but it has the disadvantage of having a high torque tendency (it tends to untwist when tension load is applied) compared with ordinary laid rope. Untwisting can be dangerous with a steel-cored rope: load is shed from the strands and may cause the core to fail as it becomes higher loaded. Cable flexibility depends on the number of wires in the cable (more wires=more flexible) and the diameter of the wires (thinner wire=more flexible) The flexibility of the cable is important in cables used in machinery such as cranes and elevators as well as transportation uses (in cable cars, cable railways, and aerial lifts). Cable flexibility is less important for cables used in suspension bridges. Galvanized Galvanized to finished size Has a strength 10% lower than standard Bright Wire. The finished cable is run through the galvanized process This increases the diameter of the cable, making it less flexible. Drawn Galvanized Wire Is galvanized before cable is braided Equal in strength and size to Bright Wire Stainless Steel High resistance to any corrosive conditions Used extensively in yachting and control cables Plastics (polyethylene coating/tube) Steel cable must be terminated in certain methods to prevent unraveling of the cable. Most common termination style is to turn the end of the rope back and secure it to rest of the cable making a loop. Making the loop requires tools to create the loop Thimble-prevents too tight of a bend in the cable Clip/Clamp-fixes the loose ends back to the rest of the cable Swaged Terminates two wire rope ends together or terminates one wire rope end to something else. Wedged Sockets Used when a fitting needs to be replace frequently. Potted Ends Creates a high strength permanent termination. Eye Splice (Flemish Eye) May be used to secure the loose ends of the cable when forming a loop Wire ropes are labeled based on a coding system that describes the number of strands in the rope, number of wires in the strand, the material in the core, and the lays of the rope. i.e. 6*19 FC RH OL FSWR Bridges Cranes Elevators Supports Cargo Derricks Tightrope Walking . Mechanical Cable Construction. 21 November 2010 <http://www.savacable.com/pages/applic_01.html>. . Military Cables and Assemblies. 22 November 2010 <http://www.picwire.com/military.html>. . Wire rope. 27 November 2010. 21 November 2010 <http://en.wikipedia.org/wiki/wire_rope>. . Wire Rope Hardware. 2010. 22 November 2010 <http://www.gbgindustries.com/standardhardware.htm>. Questions?