Modelling of Atomic Force Microscope(AFM)

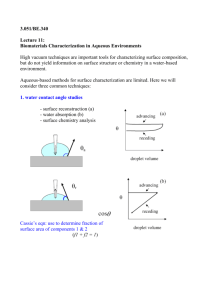

advertisement

Deng Wenqi Supervisors: Guang-Ming Zhang,Dave Harvey, Francis Lilley Outline Background of AFM Brief introduction of Comsol Multiphysics Simulation and results Project plan How AFM works? •The x and y-piezos provide lateral scanning(~30nm) , while the z-piezo extends and retracts to follow the surface topography(up to 0.1nm) . Image mode Non-contact mode •The cantilever is oscillated near its resonant frequency at a position just above the sample surface •Measures the topography by detecting the vibration amplitude affected by the attractive forces •Difficult to use in normal ambient conditions •Better to use in ultra high vacuum conditions Image mode Contact mode •Constant force during scanning •Damage soft sample Image mode Tapping mode •The cantilever is vibrated at its resonant frequency •Intermittent contact with sample • Reduce sample destruction Phase imaging •Measure the phase lag of the cantilever oscillation (solid wave) relative to the phase of the piezo drive (dashed wave). •The amplitude signal is used simultaneously by the controller for Tapping Mode feedback. • Spatial variations in sample properties cause shifts in the cantilever phase (bottom) Why phase image provides more information of structure? Topography (left) & phase (right) images of a composite polymer •Higher spots in the AFM topography images should correspond to the hard phase polymer? •Brighter areas correspond to harder materials? •We don’t have an agreement yet. First model •Model consists of a piezo actuator, a cantilever and the tip. • A sinusoidal voltage signal is applied to piezo( purple block) Free vibration results •Vibration curve is not smooth Contact model •Define contact pair between the tip and sample •Omit the inertial effect •Start with linear discretization model Displacement and contact force curves •Bouncing effect Quasi-static study Bouncing effect disappear Smooth curves •Free vibration Quasi-static study Different materials such as cooper,GaAs,Ge,Si,andpolymer are tested Contact force curve of cooper Phase curve Phase shift Light contact Young’s modulus Phase shift Deeper contact Young’s modulus Phase curve Phase shift Phase shift Tip sample separation(Polymer) Tip sample separation(Copper) Problems of static study It omits the inertial effect of the whole model Does not reflect the resonant frequency of the cantilever No matter what frequency you apply, the amplitude is almost the same. Problem of resonant frequency When using linear discretization model, the resonant frequency is not right. Different mesh lead to different results 1.15e5 Hz 2.69e5 Hz This problem will not occur when changing to quadratic discretization. 82424.8 Hz 82425 Hz New model AFM Probe Type: PNP-DB Manufacturer: NanoWorld Geometry built in COMSOL lLength Width Thickness Resonant Frequency 100 µm 13.5um 0.6um 67kHz Eigenfrequency Study Resonant frequency is 82424Hz Time dependent study 1 Fixed boundary Edge load=sin(2*pi*f*t)*100[nN] Mesh Free vibration Time dependent study 2 •Apply the contact force on the tip 1.Treat the contact force as spring 2.Relate the contact force with Young’s modulus of tip and sample Displacement curves of the cantilever •Phase shift between green and blue is 3.8 degree •Phase shift between red and blue is is 4 degree Time dependent study 2 Load a force on the sample for a short period Unload the force, sample almost recovered Problems of simulation Difficult to define the contact force equation It’s better to model tip and sample together However, it is still difficult to solve contact modelling in time dependent study. Contact model Project Plan Aim: 1) Phase interpretation 2) Nano-NDE(non-destructive evaluation) for defect detection, imaging of internal micro-structures, measurement of mechanical properties. Test samples: 1) Single layer samples with surface defects. 2) Multiple layers samples with defects Project Plan Methodologies Elastic deformation force only Elastic deformation force + Van Der Waals Curve of phase shift vs height Curve of phase shift vs material Image restoration using these curves: material phase image Project Plan Future work Solve the problem of contact modelling Define the relationship between phase shift and material parameter, such as phase shift vs young’s modulus, phase shift vs thickness Observe how phase change in non-destructive evaluation, eg. The sample has a defect inside Test soft material like cells and compare the results with real experiment Thank you!!! Any Questions?