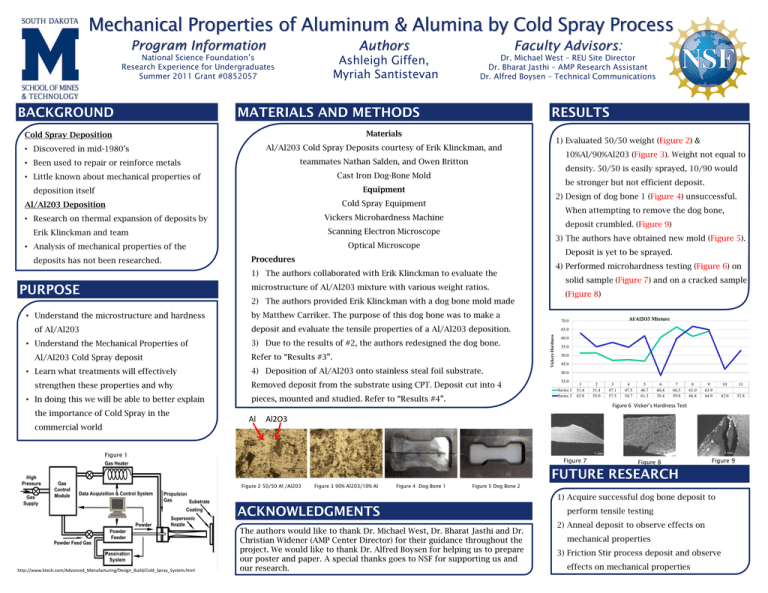

Al/Al203 Deposition

advertisement

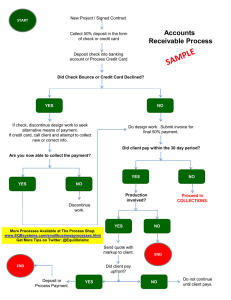

Mechanical Properties of Aluminum & Alumina by Cold Spray Process Program Information National Science Foundation’s Research Experience for Undergraduates Summer 2011 Grant #0852057 BACKGROUND Authors Faculty Advisors: Ashleigh Giffen, Myriah Santistevan Dr. Michael West – REU Site Director Dr. Bharat Jasthi – AMP Research Assistant Dr. Alfred Boysen – Technical Communications MATERIALS AND METHODS Materials Cold Spray Deposition 1) Evaluated 50/50 weight (Figure 2) & Al/Al203 Cold Spray Deposits courtesy of Erik Klinckman, and • Discovered in mid-1980’s 10%Al/90%Al203 (Figure 3). Weight not equal to teammates Nathan Salden, and Owen Britton • Been used to repair or reinforce metals density. 50/50 is easily sprayed, 10/90 would Cast Iron Dog-Bone Mold • Little known about mechanical properties of deposition itself Equipment Al/Al203 Deposition Cold Spray Equipment be stronger but not efficient deposit. 2) Design of dog bone 1 (Figure 4) unsuccessful. When attempting to remove the dog bone, Vickers Microhardness Machine • Research on thermal expansion of deposits by deposit crumbled. (Figure 9) Scanning Electron Microscope Erik Klinckman and team 3) The authors have obtained new mold (Figure 5). Optical Microscope • Analysis of mechanical properties of the deposits has not been researched. RESULTS Deposit is yet to be sprayed. Procedures 4) Performed microhardness testing (Figure 6) on 1) The authors collaborated with Erik Klinckman to evaluate the PURPOSE solid sample (Figure 7) and on a cracked sample microstructure of Al/Al203 mixture with various weight ratios. (Figure 8) 2) The authors provided Erik Klinckman with a dog bone mold made • Understand the microstructure and hardness by Matthew Carriker. The purpose of this dog bone was to make a deposit and evaluate the tensile properties of a Al/Al203 deposition. • Understand the Mechanical Properties of Al/Al203 Cold Spray deposit • Learn what treatments will effectively strengthen these properties and why • In doing this we will be able to better explain the importance of Cold Spray in the commercial world 3) Due to the results of #2, the authors redesigned the dog bone. Refer to “Results #3”. 4) Deposition of Al/Al203 onto stainless steal foil substrate. Removed deposit from the substrate using CPT. Deposit cut into 4 pieces, mounted and studied. Refer to “Results #4”. Al 65.0 Vickers Hardness of Al/Al203 Al/Al2O3 Mixture 70.0 60.0 55.0 50.0 45.0 40.0 35.0 Series 1 Series 2 1 51.4 62.8 2 51.4 55.0 3 47.1 57.5 4 47.5 54.7 5 46.7 61.3 6 60.4 38.4 7 66.5 59.8 8 61.0 66.8 9 63.9 64.9 10 11 42.0 52.8 Figure 6 Vicker’s Hardness Test Al2O3 Figure 1 Figure 7 Figure 8 Figure 9 FUTURE RESEARCH Figure 2 50/50 Al /Al203 Figure 3 90% Al203/10% Al Figure 4 Dog Bone 1 Figure 5 Dog Bone 2 1) Acquire successful dog bone deposit to ACKNOWLEDGMENTS http://www.ktech.com/Advanced_Manufacturing/Design_Build/Cold_Spray_System.html The authors would like to thank Dr. Michael West, Dr. Bharat Jasthi and Dr. Christian Widener (AMP Center Director) for their guidance throughout the project. We would like to thank Dr. Alfred Boysen for helping us to prepare our poster and paper. A special thanks goes to NSF for supporting us and our research. perform tensile testing 2) Anneal deposit to observe effects on mechanical properties 3) Friction Stir process deposit and observe effects on mechanical properties