the Power Point presentation from the 2010 Fall Workshop

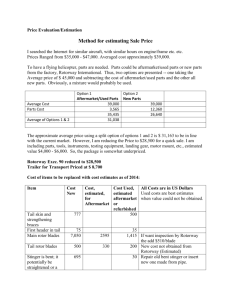

advertisement

Helicopter Duration at Science Olympiad Nationals 2010 Thomas Stokes, Jackson Amodeo 11th Place, 2010 Nationals Kenwood Trail Middle School, Lakeville MN Hap Stokes, Mentor, hapstokes@gmail.com MN Science Olympiad 2010 Student & Coach Workshop 13-Nov-2010 Typical Science Olympiad Designs Wright Bat – 1 rotor means time bonus Parlor Copter – 2 Rotors Whirlibird – 2 rotors Adding a center spar on top allows the helicopter to rise to the ceiling and spin freely, making it a “Ceiling Walker” Early rejected designs Penni Helicopter Heavy, Complex, Gimmicky Parlor Helicopter with tube motor stick Difficult to wind, Very heavy Our helicopters Designed for trial and error with adjustable rotor pitch. 6.1 gm helicopter and 2 gm rubber motor = 8.1 gm Helicopter Design Variables Discussion What we did Weight Min. 4 gms total, including rubber 2 gms max. Balsa wood. We always made 2 gm motors. Copter was 6.1 gms, = 8.1 grams total. Too heavy. Rotor shape & type Fixed vs. variable pitch vs. airfoil. Solid balsa vs. film on frame. For simplicity of construction we used flat rotors, film on frame. Rotor diameter 40 cm max We used it all. Rotor surface area Big surface adds more lift, but also more weight and drag. We kept this constant. In hindsight we should have had less surface area. Rotor angle of attack If you have enough power, increase angle until it stalls This was our primary variable, and our helicopter had adjustable angles. We ran at 18-20 degrees. Motor (rubber band) thickness The more rubber you have, the more power you can deliver, but also the more tension must be withstood by the motor stick, which might require thicker stick (adds weight). We used 1/8” rubber, lubricated with ArmorAll. Motor length Determines how many winds can be stored in the motor We used doubled rubber bands 22.5”. Too short. Motor # winds Determines flight time. More winds means more stress on the motor stick. With our heavy rubber and large rotors, we could only crank about 240 winds max, which limited our flight time. Best at Nationals was 36 seconds, enough for 11th place. We used plastic O rings to make it easier to transfer from winder to tail hook. Math – Lift Equations • www.aerospaceweb.org Variable Description L lift force air density V aircraft velocity Sref reference area CL coefficient of lift • “The Propeller Propulsion Science Olympiad” by Lew Gitlow • For 6th graders, this math is too complicated. • We chose “Trial and Error” strategy Recommendations 1. Buy a kit, build it – – 2. Fly the kit, try not to break it, learn from it – – 3. To make sure partners are clear, write commands for winding & launching KISS (keep it simple stupid) – – 8. Weight is everything (target 4 grams total) Power is everything else. More winds for better duration don’t matter if it doesn’t fly. Build a stooge to hold the copter during winding – 7. center mast for “ceiling walker” vs. slow climber because of rafters Decide what you can design with math – – 6. scioly.org, soinc.org look for Jeff Anderson, Livonia, MI Learn about the ceiling, design for the ceiling – 5. We couldn’t get the kit to fly. Why not? We broke the kit before we could really learn why Read Blogs – – 4. One source A2Z Corp, Englewood, CO, USA Learn about building jigs, balsa strength, glue types, glue techniques Fix some variables Don’t sweat the fine tuning the blogs talk about. Focus on weight and power to getting it flying first. Plan to build more than one, as you will break them Design for the Ceiling Nationals 2010 Univ Illinois Armory - 98ft ceiling Minnesota State 2011 McCarthy Gym, St. Thomas Support Equipment Design Jigs (foam core board) Carriers • Rotor angle jig • Protractor Angle Gauge • 1:1 scale rotor patterns (below) • Travel Bin • Winding Stooge (below) Regular Pins Push Pins 1 3 5 6 4 2 Misc • Winder • Scale The Ultimate Goal • Light = 4 grams • Variable pitch rotors = higher efficiency • Heavy motor stick to allow many winds • Center spar to allow long ceiling walks