Additional Development Training for Safety Representatives

advertisement

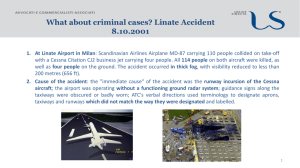

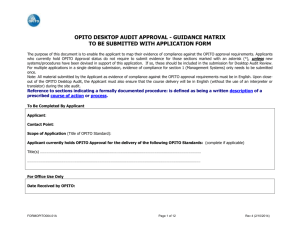

Additional Development Training for Safety Representatives ESR Perspectives Event 28-November 2012 Nicky Elphinstone, ESR Step Change in Safety Leadership Team Nicol Webster, OPITO Standards and Development M a k i n g t h e U K t h e s a f e s t p l a c e t o w o r k i n t h e w o r l d w i d e o i l a n d g a s i n d u s t r y. Why additional training for safety reps? • SI 971 Regulation 27 Training: “It shall be the duty of the duty holder to ensure that a) b) a safety representative for the installation is provided with such training in aspects of the functions of a safety representative as are reasonable in all the circumstances; and any costs associated with such training, including travel and subsistence costs, are not borne by the safety representative.” • SI 971 Guidance 105: “As a follow-up, consideration should also be given to developmental training needs” • ESRs and trade unions campaigned vigorously for more training • Duty-holders struggling to find appropriate courses in the market • HSE SI 971 Inspection Programme – lack of involvement in key areas • OIAC WIG identified 4 key priority areas for action Leadership Commitment • Significant buy-in at senior levels in industry • OIAC WIG proposal endorsed by Step Change leadership team • WIG asked OPITO to develop an industry training standard to cover the 4 key priority areas Workforce Involvement • Listened to the feedback at SCiS & WIG events • OPITO Industry Work Group made up mainly of ESRs (developed by your peers) OPITO training standard process Demand for training (ESRs, Unions, HSE, WIG, Step Change, OGUK, employers) May June Work group July August Draft standard September October Consult & revise November December Pilot courses January February OPITO standard March Approved training provider courses Q2 2013 Training aim • Support improved health and safety through more effective workforce involvement, by giving safety representatives access to training that helps them develop their effectiveness and confidence to: 1. Understand and identify major accident hazards; 2. Understand risk analysis to get involved in preparing/ revising safety cases; 3. Investigate incidents and apply root cause analysis; 4. Conduct independent inspections and audits and present findings and concerns effectively. 4 pick-and-mix modules Existing Basic Courses Initial Offshore Safety Representative Training Refresher Offshore Safety Representative Training Pre-requisite Additional Development Training Module 1: Major Accident Hazards 2 days Module 2: Risk Analysis 2 days Module 3: Root Cause Analysis 2 days Module 4: Inspect/Audit/ Communicate 2 days Expectation Common threads Empowerment Confidence Personal skills Not mandatory Not assessed Not e-learning Not at workplace Effectiveness Experiential learning Action plans & networks Pilot courses to test draft standard Course Pilot course dates Major Accident Hazards 1 Designed to give ESRs a broad understanding of major accident hazards and safety critical elements in the context of UK offshore safety cases and performance monitoring systems 18-19 Feb 2013 Risk Analysis 2 Designed to give ESRs enough understanding of how risk management is applied in safety cases and safety management systems, so they are not blinded by jargon and are encouraged to become personally involved in preparing or revising safety cases 25-26 Feb 2013 Root Cause Analysis 3 Designed to give ESRs enough understanding of accident causation and root cause analysis to encourage them to become personally involved in incident investigation, and to question and challenge until they get to root causes 27-28 Feb 2013 Inspect / Audit /Communicate 4 Designed to give ESRs enough understanding and confidence to become personally involved in inspections and audits, and to use personal effectiveness and communication skills to secure remedial action if necessary 17-18 Dec 2012 Module 1: Major Accident Hazards • Major accident hazards and safety critical elements • Identifying MAH and SCE outside rep’s own discipline • The principles and structure of safety cases under the regulations • Using an actual offshore safety case • Safety representatives’ rights of access to safety cases • How to access and understand installation safety case information • Performance standards, written schemes of examination & verification • Practical examples of performance standards, formats & topical KPIs • Practical aspects of getting and understanding safety case information • A clear action plan to increase personal involvement in reviewing major hazard management arrangements set out in safety case Module 2: Risk Analysis • The concept of major accident risk and its application in the offshore industry • Case studies to illustrate hazards, risks and controls, and the types of failure modes that led to major accidents • The range of formal safety assessment and risk analysis processes & techniques • The role of human error and organisational failure in accident causation • Common failures in risk analysis & the need to challenge assumptions • When to challenge risk assumptions and how to seek expert advice • The safety representative’s role and involvement in risk analysis • How to get involved effectively in formal safety assessment & risk analysis • A clear action plan to increase personal involvement in risk analysis Module 3: Investigate incidents (RCA) • The ESR’s role and involvement in incident investigation • Accident causation and root cause analysis techniques • Skills involved in exploring incidents to root causes • Human factors, safety culture, behavioural/organisational failure types • Practical and realistic investigation skills in the offshore environment • Conducting your own incident investigation and overcoming barriers • Preparing written incident investigation reports • Identifying trends and patterns and securing remedial action • Presenting results and recommendations and using personal power and assertiveness to secure remedial action • A clear action plan to increase personal involvement in incident investigation and analysis Module 4: Inspect / Audit / Communicate • The ESR’s right to conduct independent inspections and audits • Inspection skills and techniques • Planning and conducting a safety inspection • Safety audit structures, processes and levels – key roles involved • Effective reporting and presentation of inspection/audit findings • Influencing people to reach a satisfactory conclusion for all sides • Practice in preparing effective reports and written communications • Practice in effective presentations to different target audiences • Overcoming barriers to conduct independent inspections and audits • A clear action plan to increase personal involvement in inspections & audits Pilot courses • Run by Det Norske Veritas (DNV) – Cromarty House, 67-72 Regent Quay, Aberdeen, AB11 5AR • Purpose of pilot is to test the unpublished standard – – – – – 12 places per course Must have done basic 4½-day course DNV/Step Change certificate (not OPITO) Course fee for pilots £650 per delegate per module Duty-holder expected to pay for the training costs Pilot course Dates 1. Major Accident Hazards 18th – 19th February 2013 2. Risk Analysis 25th – 26th February 2013 3. Root Cause Analysis 27th – 28th February 2013 4. Inspect/Audit/Communicate 17th – 18th December 2012 For more information • About the training standard: – nicol.webster@opito.com • About registering for the pilot courses: – Nichola.Dickson.Reid@dnv.com tel 01224 335115 • About any problems with payment, etc.: – esr@stepchangeinsafety.net