SES_4

SESSION 4

Drainage Design

Considerations

Objectives

Identify types of subsurface drainage

Determine need for subsurface drainage

Recognize importance of maintenance

Identify surface drainage design factors

Introduction

Moisture is a major cause of distress

Drainage long recognized as key design consideration

Focus on drainage of surface infiltration water

Effect of Drainage

Moisture-Related

Distresses

Moisture-Related

Distresses

Moisture-Related

Distresses

Moisture-Related

Distresses

Approaches to Drainage

Problems

Seal the pavement

Use moisture-insensitive materials

Install subsurface drainage

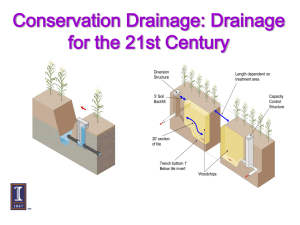

Types of Subsurface

Drainage

Daylighted bases

Longitudinal edge drain system

Drainable pavement system

Daylighted

Traffic Lane

Agg. Base

Subgrade

Traffic Lane

Aggregate Base

Carried

Out to Ditchline

Aggregate Base

Carried

Out to Ditchline

Longitudinal Edge Drain

System

Inner Shoulder Traveled Way

PCC

Slope

Slope

PCCP PCCP

Outer Shoulder

Slope

PCC

TPM

Base (LCB, ACB)

Filter Fabric, High Side of

Tangents and Superelevations

California Design

Filter

Fabric

Example Drainable

Pavement System

AC

Shoulder

PCC Mainline

AC

Shoulder

Geotextile

Aggregate Separator

Layer Permeable

Base

Geotextile

Components of a Drainable

Pavement System

Permeable base

Separator layer

Longitudinal collector pipe

Permeable Base

Permeability of

300 to 3,000 m/day (1,000 to

10,000 ft/day)

100 to150 mm

(4 to 6 in) thick

Treated or untreated

Separator Layer

Prevent intrusion of fines into permeable base

Dense-graded aggregate

Geotextile

Longitudinal Collector Pipe

Collects water and outlets to ditches

Typically 100 to 150 mm (4 to 6 in) corrugated plastic pipe

Outlet spacing 76 to 150 m (250 to

500 ft)

Design and Analysis of

Drainage Systems

Define

Material properties

Roadway/pavement geometrics

Climatic data

Determine inflow/outflow characteristics

Determine drainage requirements

Consideration of Drainage in Slab Thickness Design

AASHTO Drainage Coefficient

Drainage , Thickness

Reduction in properties of paving materials

Determining Need for

Subsurface Drainage

Available free moisture

Material properties

Cross sectional design

Subgrade drainability

Traffic levels

NCHRP 1-32

Drainage Guidelines

ESALs,

WET CLIMATE

Weak Strong

DRY CLIMATE

Weak Strong millions Subgrade Subgrade Subgrade Subgrade

< 3.0

None

3.0 - 6.0 None/EDS None None None

> 6.0

EDS/DPS

EDS = Longitudinal Edge Drain System

DPS = Drainable Pavement System

Inclusion of

Subsurface Drainage

Local experience

Past performance

Cost effectiveness

Construction and maintenance practices

Maintenance of Drainage

Installations

Ensures functionality of drainage system

Often a “forgotten” maintenance item

Activities include:

Reference markers

Cleaning outlets

Flushing/rodding edge drains

Cleaning/reestablishing ditches

Periodic video inspection

Video Inspection of Edge

Drains

Crushed Pipe and Silt

Buildup

Unwanted Inhabitants

Surface Drainage

Considerations

Pavement cross slope (tangent section)

2% recommended

Shoulder cross slope

3% recommended

Ditches

Width: 0.9 to 1.2 m (3 to 4 ft)

Depth: 1.2 m (4 ft) beneath pavement

Grade: 1%

Summary

Moisture-related distresses

Subsurface drainage types

Determining need for subsurface drainage

Maintenance considerations

Surface drainage considerations