First Article Inspection 9102

advertisement

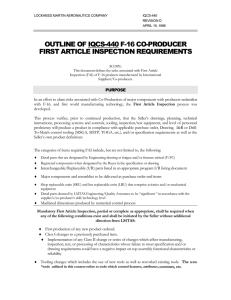

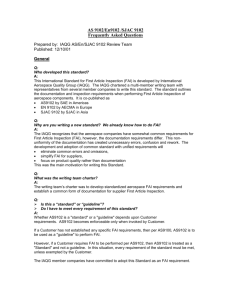

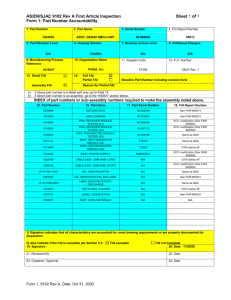

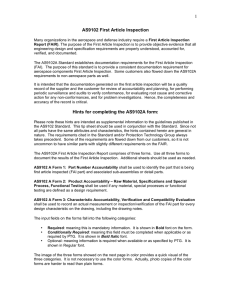

First Article Inspection 9102 Carl Zimmerman Sept,2013 Purpose: •The purpose of the First Article Inspection is to give objective evidence that all engineering, design and specification requirements are correctly understood, accounted for, verified, and recorded. The purpose of this standard is to provide a consistent documentation requirement for aerospace components FAI. Why is First Article Inspection important? Aerospace design and manufacture is complex • Requirements are stringent (eg. MBD, tolerances, performance, etc.) • Reliance on Specifications (material, process, methods, etc.) Conformance to all design requirements is required • Public Safety – We all fly • Demonstrate product conformance, with objective evidence Why is First Article Inspection important? FAI is a fundamental QMS process • Verifies that defined manufacturing methods, tooling, equipment, training, instructions, etc. results in conformance to design • Ensures nonconformances are identified, and action is taken, until results conform to design • Not just a quality records generating process for inspection • Involves all Product Realization related departments (e.g. Engineering, Procurement, Manufacturing, Quality, Tooling, etc.) • FAI process is concurrent with product planning and manufacture Why is First Article Inspection important? Continual Improvement activity • Formal QMS process (e.g. requirements, process definition, quality records, assigned personnel, etc.) • Drives change to the applicable QMS process, as part of corrective action process • Design, Procurement, Manufacturing, Tooling, Equipment, etc. • Supports cost reduction (Cost of poor quality) • Eliminate repetitive nonconformances • Eliminate/reduce NoEs (First Part and on) • Supports improved delivery • Stable and controlled production processes • On-time delivery commitments Why is First Article Inspection important? • FAI Planning needs to begin with production planning • Detailed FAI procedures are important for level setting with customers • Complete FAI needs to be presented with first production delivery • Dealing with non conforming characteristicsnew part after RCCA verification • Questions on why FAI is critical? • REV A- B changes

![Purchase Order Review [PPT]](http://s2.studylib.net/store/data/005611999_1-c8ef198c871b79ffb906a13488b756ed-300x300.png)