Bunker_Project

advertisement

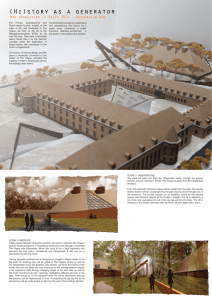

ESS Bunker Project Zvonko Lazić www.europeanspallationsource.se September, 2014 Layout The central ESS building is home to the target systems and majority of instruments. The target monolith is shielded by ‘the bunker’. The Bunker is created by stacking (concrete) blocks around the monolith in sufficient depth to reduce radiation levels in the surrounding environment to acceptable level. 2 Layout Since no instrument is fully defined yet, we continue with the bunker design with following caveats: • We concentrate initial efforts to the upper portion of the bunker, • Select and develop stacking strategy, • Support structure for the bunker will be developed at a later stage, once we have better idea of instruments placement, • Parallel to this effort, the physics part of the project is developing concrete formulation(s) to be used for production of bunker blocks, 3 Initial Brief – Bunker profile Crane hook height Target axis Bunker profile up to R15m Target Centre Beam-guide axis Instruments ‘floor’ CF floor Requirements are plenty and contradicting: Maximize block size to the crane capacity Minimize number of blocks Maximize radiation protection Allow for ease of assembly and disassembly Minimize number of ‘lifts’ required to reach key components under the bunker 4 Initial work – Concepts Initial brief is answered with a series of hand-drawn concepts. Three main concept directions are identified and discussed. • • • Maximizing all block sizes to the crane capacity (this reduces the number of blocks in the assembly, therefore reduces the number of required lifts to access hardware underneath, minimizes the number of joining surfaces/planes therefore maximizes the radiation protection. Introducing “in-between-blocks” (creating option above with smaller “joining blocks” which can be attached to either one of the neighboring blocks; this minimizes number of lifts). Using “pavement” layout (all blocks are the same size/shape; lying down the pattern is done disregarding angular nature of an instrument ‘wedge’). 5 Initial work – Developing concepts Model initial concept; evaluation done on the following criteria Number of lifts Shielding performance Manufacturing complexity Section through the stacked bunker to show joining planes (x-z and x-y planes) 6 Initial work – Developing concepts Unstacking one instrument “wedge” up to R15m and unstacking one complete instrument “wedge” 7 Initial work – Developing concepts Second concept showing general layout and stacking section 8 Initial work – Developing concepts Second concept showing Unstacking sequence for one instrument “wedge” 9 Initial work – Developing concepts “Tile” concept 10 Initial work – Developing concepts Unstacking sequence and y-z section 11 Summary • Bunker roadmap – Evaluate different stacking concepts – Design supporting structure taking into account instruments (space) and other requirements – Detailed design • Mix formulation concluded (we know what are the material properties) • Blocks manufacturing technique(s) determined (cast in shell or..) • Supporting structure detailed analysis • IKC or supplier… • Production 12