Uncle Grump Toys – A Case Study on Performance

advertisement

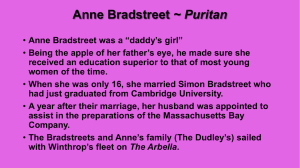

Uncle Grump Toys – A Case Study on Performance Evaluation & Decision Making R Sivakumar 1 Part – 1 The Case One morning, John Worby, President of Uncle Grumps Toys, sat down with Anne McMullen, Executive Vice President, to discuss year-end performance evaluations of the management group. These discussions were important because the company had traditionally given managers a sizeable bonus based on their evaluation. To the extent that it was possible, John and Anne preferred to base their EVALUATION ON OBJECTIVE MEASURES OF PERFORMANCE WITH AN EMPHASIS ON ACHIEVEMENT OF BUDGETED GOALS. 2 The BUDGET PROCESS began in late August and by mid-November the management team supplied the board of directors with a complete budget outlining monthly sales estimates, production cost estimates, and capital spending requirements. The directors then discussed the implications of the budget and, upon acceptance, authorized it. The firm's progress throughout the year was MONITORED AGAINST THIS BUDGET EVERY SIX MONTHS at the board meetings which were held on the 15th January and 15th July. At the January meeting the board also voted on the management bonuses for the prior year. 3 Uncle Grumps toys was a BOSTONBASED COMPANY that manufactured a very SUCCESSFUL LINE OF FOAM RUBBER TOYS CALLED "UNCLE GRUMPS". These were cuddly Hobbit-like dolls with large noses, a discerning smile, and enormous feet, which SOLD FOR RS.25 WHOLESALE. From the moment of introduction, they had been a runaway success. Plans to expand the line were on the drawing board and A SMALLER BABY VERSION WAS TO BE INTRODUCED IN THE SPRING OF 1988. 4 The business was HIGHLY SEASONAL with over half of the sales occurring from mid-August to early November. This was followed by a two-month trough before birthday and occasional gift sales picked up again. Sales were then fairly STATIC until the next Christmas rush began. BUDGETED SALES FOR 1987 WERE RS.500 LACS WITH A STANDARD GROSS MARGIN, ON FULL COST, OF 25%. 5 Management had decided that even though sales were highly seasonal, PRODUCTION WOULD BE LEVEL THROUGHOUT THE YEAR. This enabled Uncle Grumps Toys to stabilize employment and to sell a greater number of toys during the Christmas period than would have been possible if a shift approach had been used. Current production was at full capacity using ONE SHIFT A DAY, FIVE DAYS A WEEK. In 1986, sales were considerably greater than expectation and had almost resulted in orders being rejected due to a lack of inventory. In fact, BY YEAR-END, ONLY 50,000 TOYS WERE LEFT IN STOCK. 6 John and Anne decided to discuss the production manager's performance first. The production manager, Holly Frost, had been with the firm for just over a year and this was to be her first bonus. John and Anne admired Holly and felt she had been VERY INNOVATIVE and had substantially improved the production process. One improvement, introduced at the beginning of the third quarter, resulted in the average material content of each toy being reduced from 5 lbs. to 4.5 lbs., a substantial savings. 7 In measuring Holly's managerial performance, John and Anne felt that some adjustment was necessary because 1987 had been a rather turbulent year. The factory had been closed from February 5 to March 4 (20 working days) due to "The Great Blizzard of 1987", and then the factory roof collapsed under the weight of three feet of snow. During this period, employees DID NOT WORK BUT WERE GIVEN HALF PAY. To MAKE UP FOR LOST PRODUCTION, A FOUR HOUR SATURDAY MORNING SHIFT was introduced from March 7 until the end of the year. Employees were paid time-and-a-half for this 8 work. Additional overtime was required in the fourth quarter when the sales department managed to gain a Rs.10 lacs order from a catalog sales company for an extra 50000 toys. The order was placed in the middle of October and, along with other orders, required that OVERTIME BE INCREASED TO 16 HOURS PER WEEK-END, at time-and-a-half, for six week-ends (this includes the Saturday morning time already planned). SALES For 1987 WERE 21 LACS UNITS. 9 John and Anne started with the budgeted and actual figures reported in Exhibit 1. The company had not implemented a STANDARD COST SYSTEM (EXCEPT FOR VALUING THE RAW MATERIAL INVENTORY). Because unit costs were relatively stable, direct materials were tracked in pounds, direct labour in hours, and actual usage was compared with budget. Before they could adequately Judge Holly's performance, however, John and Anne decided they needed additional information. John spoke with the materials inventory clerk and came back with an inventory listing (Exhibit 2) and a reminder that the COMPANY USED FIFO INVENTORY COSTING. 10 Anne spoke with the pay-roll clerk and was given a summary of monthly payroll listings (Exhibit 3). Looking at the pile of information they had collected, John and Anne settled down to the process of evaluating Holly's performance. After several hours, John and Anne took a break. They felt they had made progress but still were NOT CERTAIN THAT THEY KNEW HOW HOLLY HAD PERFORMED. 11 Over coffee, Anne remarked to John, "Well, now we have a lot of facts, but it is not clear to me how we can use these figures to analyze Holly's performance". "I have the same concern", replied John. 'There are so many numbers and only some are relevant to Holly"."I know, but which ones? That's the question". "That's first on the agenda, when we finish coffee. But there is something else that is bothering me and that is a comment Holly made about those catalog sales", said John. "What was that?" asked Anne. "Well, Holly thinks we lost money on the deal because we sold them to the catalog company below cost". "Didn't you explain to her about contribution analysis?", asked Anne. "Well, yes, but she said she understood that, and we were still losing out. Unfortunately, she was called away before she could explain to me what she meant". 12 QUESTIONS: Evaluate the performance of Holly Frost as production manager in each quarter of 1987. Was the special deal made with the catalog company a good idea? Explain. 13 EXHIBIT 1 : QUARTERLY PRODUCTION REPORT (all figures in thousands) Quarterly Budget Rs. Quarterly Actuals 1 2 3 Rs. Rs. Rs. Total 4 1987 Rs. Rs. Variable Costs: Raw Materials: Direct Labour Indirect Labour Supplies Power 2000* 5000** 400 100 500 2,250 3,400 300 75 360 2,750 5,220 450 100 570 3,300 5,860 420 115 540 1,700 7,350 480 130 600 10,000 21,830 1,650 420 2,070 Fixed Costs: Repairs & Maintenance Depreciation Insurance Total 500 1,000 500 10,000 465 1,000 500 8,350 385 1,000 525 11,000 550 1,000 550 12,335 540 1,000 500 12,300 1,940 4,000 2,075 43,985 Units Produced 500 * Budget based on 5 lbs. / toy. 350 550 550 600 2,050 14 ** Budget based on 1 hour / toy EXHIBIT 2 : SUMMARY OF RAW MATERIAL INVENTORY MOVEMENTS (All figures in thousands) Opening Balance (Dec. 6, 1986) Purchases (Dec.6, 1986 - Dec.4, 1987) Usage (Dec.6, 1986 - Dec.4, 1987) Closing Balance (Dec.4 , 1987) Purchases * 13 weeks ending 6.3.87 13 weeks ending 5.6.87 13 weeks ending 4.9.87 13 weeks ending 4.12.87 Total 2500 lbs 2500 lbs 3000 lbs 2000 lbs 10000 lbs 200 lbs 10000* -9600 600 Rs. 160 10000 -9680 480 Rate / lb Consumption in Rs. 0.90 1855 lbs 1.10 2860 lbs 1.10 2365 lbs 0.85 2520 lbs 9600 lbs. 15 EXHIBIT 3 : SUMMARY OF DIRECT LABOUR EXPENSES (All figures in thousands, except employees) Average No. of employees 13 weeks ending 6.3.87 13 weeks ending 5.6.87 13 weeks ending 4.9.87 13 weeks ending 4.12.87 Total 1,000 1,000 1,000 1,000 Regular hours 505* 502 508 514 2,029 Overtime hours 52 52 124 228 Cost ** 3,400 5,220 5,860 7,350 21,830 *Includes the 1,60,000 hours when factory was closed for 20 days during which time employees receive half the pay. **Holly was responsible for negotiating all labour contracts. 16 Wish you all the best R Sivakumar 17 UNCLE GRUMPS’ TOYS Part II - Case Analysis R Sivakumar Understanding the inputs Process of Budget Preparation Difficulty of Evaluation. Segregation of Expenses Preparation of Variances Controllable analysis Preparation of A Responsibility Report, Relevant cost for decisions Relevancy of Cost For Pricing Pricing policies 19 Principles of Performance Evaluation Management function that compares actual results with budget goals. Includes both behavioral and reporting principles. Principles of Performance Evaluation Behavioral Principles 1. Managers of responsibility centers should have direct input into the process of establishing budget goals of their area of responsibility. Without such input, managers may view the goals as unrealistic or arbitrarily set by top management. Such views adversely affect the managers’ motivation to meet the targeted objectives. 2. The evaluation of performance should be based entirely on matters that are controllable by the manager being evaluated. Criticism of a manager on matters outside his or her control reduces the effectiveness of the evaluation process. It leads to negative reactions by a manager and to doubts about the fairness of the company’s evaluation process. Principles of Performance Evaluation Behavioral Principles 3. Top management should support the evaluation process. As explained earlier, the evaluation process begins at the lowest level of responsibility and extends upward to the highest level of management. Managers quickly lose faith in the process when top management ignores, overrules, or bypasses established procedures for evaluation a manager’s performance. 4. The evaluation process must allow managers to respond to their evaluations. Evaluation is not a one-way street. Managers should have opportunity to defend their performance. Evaluation without feedback is both personal and ineffective 5. The evaluation should identify both good and poor performance. Praise for good performance is a powerful motivating factor for a manager. This is especially true when a manager’s compensation includes rewards for meeting budget goals. Principles of Performance Evaluation Reporting Principles 1. Contain only data controllable by manager of responsibility center. 2. Provide accurate and reliable budget data to measure performance. 3. Highlight significant differences between actual results and budget goals. 4. Be tailor-made for intended evaluation. 5. Be prepared at reasonable intervals. Standard Cost Card Particulars Materials Labour Variable OHs Fixed OHs TOTAL COST Profit SELLING PRICE Amount in Rs. 5lbs @ Rs.0.80/lbs 4 1 hour @ Rs.10/hour 10 1 hour @ Rs.2/hour 2 Rs. 4 per unit 4 20 @25% on Full Cost 5 25 24 Material Usage Variance Units Produced Standard Consumption (5 lbs per unit) Revised Standard (4.5 lbs per unit) Actual Consumption Material Usage Variance (lbs) Material Usage Variance (Rs.) @0.80 / lbs Proportion Basic Production Additional Production Extra Order TOTAL Revision Variance for Basic Production (lbs) Revision Variance for Basic Production (Rs.) Qtr 1 Qtr 2 Qtr 3 Qtr 4 350 550 550 600 1,750 2,750 2,750 3,000 2,475 2,700 1,855 2,860 2,365 2,520 -105 -110 110 180 -84 -88 88 144 -84 0 0 -84 -80 -8 0 -88 80 8 0 88 250 200 120 12 12 144 250 200 25 MATERIAL PRICE VARIANCE NOTE : Raw Material Price Variance can also be computed with Actual Purchase quantity 26 Labour Analysis STD. HRS. FOR ACT. PRODN BASIC RESCHEDULE SPECIAL ORDER TOTAL ACTUAL HOUR BASIC RESCHEDULE SPECIAL ORDER HALF DAY TOTAL EQUIVALENT HRS. ACTUAL PAY ACTUAL RATE PER HR. 1 350 ----- ----- 2 500 50 --- 3 500 50 --- 350 550 550 345 502 52 508 52 4 500 50 50 600 514 52 72 ----160 ------505 554 560 638 425 580 586 700 3400 5220 5860 7350 8 9 10 10.5 27 Labour Variances Labour efficiency basic Additional Extra Rate basic Additional Spl. Order Cost Overtime (p) 1 50 50 690 690 740 (640) 2 (20) (20) (40) 502 52 554 814 26 3 (80) (20) (100) (100) - 4 (140) (20) (220) (380) (257) (26) (36) (319) (699) (31) 28 Overhead Variances Qtr 1 Qtr 2 Qtr 3 Qtr 4 Var OHs Efficiency 10 -8 -20 -76 Expenses -45 -12 45 66 Cost -35 -20 25 -10 Fixed OH Repairs 35 115 -50 -40 Depreciation -25 -50 Cost 35 90 -100 -40 29 Performance Evaluation – Comparison of Actuals With Revised Budget Units Raw material Labour Overtime Half day Variable oh Fixed oh Repairs Dep & insu Total Variance REVISED BUDGET 1 2 3 350 550 550 Rs. Rs. Rs. 1,400 2,200 1,980 3,500 5,500 5,500 260 260 700 1,100 1,100 500 1,500 7,600 500 1,500 11,060 500 1,500 10,840 ACTUALS 4 600 1 350 2 550 3 550 4 600 Rs. 2,160 6,000 620 1,200 Rs. 1,734 2,760 640 735 Rs. 3,038 4,986 234 1,120 Rs. 2,792 5,600 260 1,075 Rs. 2,116 6,699 651 1,210 500 1,500 11,980 465 1,500 7,834 (234) 385 1,525 11,288 (228) 550 1,550 11,827 (987) 540 1,500 12,716 (736) 30 Segregation of Controllable Variances MUV MPV MCV LEV LRV LCV OTP Qtr 1 Qtr 2 Qtr 3 Qtr 4 Total -84 -88 88 144 60 -250 -750 -900 -100 -2,000 -334 -838 -812 44 -1,940 Controllable Variance Diff 36 24 0 -2,000 36 -1,976 50 690 740 -640 -40 554 514 26 -100 0 -100 0 -380 -319 -699 -31 -470 925 455 -645 -190 935 745 0 -280 -10 -290 -645 -35 35 -20 90 25 -100 -10 -40 -40 -15 -40 60 0 -75 -234 -228 Revision Variance -987 -736 -2,185 VOHC FOHC 801 -2,986 400 31 Performance Report Controllable Variances Matl. Redn. At Std. Price Revision Variance Material Usage Labour Efficiency Labour Rate Variable Overheads – Cost Fixed Overheads Repairs & Maintenance Total (RS. IN ‘000) 1 QUARTERS 2 3 (84) 50 690 (35) (80) (20) 502 (20) 200 80 (80) 25 200 120 (140) (257) (10) 400 36 (190) 935 (40) 35 656 115 497 (50) 175 (40) (127) 60 1,201 4 TOTAL Note 1. : Variances concerning extra production and special order are not included in the above report. Note 2.: Labour rate is controllable as it is negotiable. Note 3.: Fixed overheads repairs & maintenance is assumed to be controllable. 32 SPECIAL ORDER Analysis of Price through Relevant Cost ACTUAL COST STANDARD COST Rs. Rs. Direct Material (50 x 4.5 x 0.85) 191 4.5 x 0.8 3.60 Direct Labour (72 x 10.5) 756 1 x 10 10.00 Overtime Premium (72 x 10.5 x 0.5) 378 1 x 5 5.00 Variable Overheads (1210 / 600 x 50) 101 1 x 2 2.00 Total Cost 1,426 20.60 Cost per Toy (1426 / 50) 28.52 Actual Price per Toy 20.00 33 All the best R Sivakumar