Single-Ply Chapter.1

advertisement

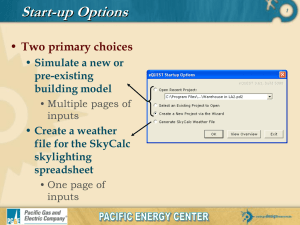

Introduction To Single-Ply Objectives When you complete this unit, you will be able to: Explain what single-ply roofing is. Describe the advantages and disadvantages of single-ply roofing. Look up the features of a single-ply material. Discuss the three factors that ensure your safety. 2 Single-Ply Roofing Single-Ply roofing is any roofing system that uses only one layer of roofing material instead of built-up layers. All single-ply systems must provide three basic qualities: Waterproofing Strength Surface protection 3 Waterproofing is provided by the roof membrane. Strength is usually provided by a reinforcement scrim (a mat of fiberglass, polyester, etc.) embedded in the membrane. 4 Scrim Makes the membrane: • Stronger •Resists punctures •Keeps it from cracking •Helps the membrane expand and contract •Improve appearance of the roof •Hold down the membrane and insulation •May be fire resistant •May reflect heat 5 MEMBRANE The membrane is a sheet of single-ply roofing. Different materials are used for the membrane. Membranes should have these features: Good appearance High tensile strength Flexibility Long life Easy maintenance Installing single-ply 6 Single-Ply Membranes Membranes must be able to: Adjust to building movement. Expand and contract with temperature changes. Hold up under aging and temperature extremes. Resist weathering. Resist the effects of ozone and ultraviolet rays. (Ozone is a form of oxygen that can be damaging. Ultraviolet (UV) rays from the sun shorten the life of the membrane.) Resist becoming brittle at very low outdoor temperatures. Resist tearing. 7 Defective Membrane 8 Membrane Thickness Membrane thickness may range from about 40 mils to 120 mils. The most common sizes are 45, 60, and 90 mils. A mil is 0.001" (one thousandth of an inch). Because membranes are relatively thin, mils are easier to use than fractions of an inch. 9 Membrane Thickness The comparison below will give you an idea of mil thicknesses: 45 mils—Slightly over 1/32" (about as thick as a dime) 60 mils—1/16" (about as thick as a nickel) 120 mils—Almost 1/8" 10 Membrane Size Membranes are usually applied in sizes as large as is practical to handle. This reduces the number of seams (which cuts down labor costs) and reduces the chance of leaks. Common sizes are 6 to 50 feet wide and 100 feet long. Some membranes are up to 250 feet long. 11 ADVANTAGES Single-ply roofing has many advantages: May be lighter than built-up roofing. May sometimes be laid over the existing roof, avoiding the cost of removing the old roof. Easier to work with: Less material to haul up to the roof. No hot bitumen and kettle to handle. Fewer seams to seal. Expands and contracts more easily. Flexible with temperature changes and movements of the building. Attractive: Comes in different colors. Adapts to any shape of roof. 12 DISADVANTAGES Single-ply roofing has these disadvantages: Products and installation methods change often because manufacturers are constantly improving the products and methods. Some products are not yet time-tested. Some membranes are damaged by grease, oil, asphalt, tar, etc. 13 DISADVANTAGES 14 Single-ply systems must be installed exactly to specs. The designer and the roofer must know what materials will damage a product. Damage to a new roof by other crafts is a constant problem. Some systems have to be installed at a certain temperature range. Shrinkage can cause damage at base flashings. Some membranes and materials have a short shelf life. (cont.) 15 Single-ply systems must be installed exactly to specs. Many solvents and adhesives are a fire hazard or health hazard. 16 Single-ply Leaks are difficult to find, especially on ballasted systems. 17 Single-ply systems must be installed exactly to specs. The system is unforgiving. The seams are the only barrier against moisture, so they have to be done right the first time. 18 Wind & Air Pressure Dangers Wind uplift has to be considered for any single-ply roof. Manufacturers have ratings for how much air pressure a roof system can withstand. Designers have wind speed maps that give the fastest wind speed for an area. Roof designs are based partly on this. 19 Wind Map Speed 20 Wind & Air Pressure Dangers 21 Wind & Air Pressure Dangers Other wind conditions have to be considered. The taller the building, the more the speed and direction of the wind on the roof can vary. The building location (for example, among tall buildings or surrounded by hills) affects wind patterns. The building structure, for example, the corners of a roof have a high wind uplift because a partial vacuum is created at the edge, especially if there is a parapet wall. The higher the parapet wall, the stronger the negative 22 pressure. Wind & Air Pressure 23 24 25 26 27 Wind & Air Pressure Dangers Air pressure from below can also be a problem. For example: A building has large overhead doors The doors are opened Air pressure rushes into the building This put pressure on the underside of the roof membrane Enough air pressure raises the membrane causing damage and leaks 28 NRCA photos of roof damage from Hurricane Charley. 29 30 31 32 33 MATERIALS There are three categories of single-ply roofing materials: Thermoplastics Modified Bitumens Elastomers 34 ELASTOMERS Elastomers have elastic, rubber-like qualities. There are two types—cured and uncured: Cured elastomers cannot be formed. They are generally used for the field membrane. Uncured elastomers can be formed. They are generally used for detailing. 35 Thermoplastics A thermoplastic becomes soft when heated and can be hot-air welded. It can be reshaped as needed for detailing. Hot-air welding fuses membranes together. 36 Modified Bitumens Modified bitumen's are asphalt sheets modified with plastics or rubber. Chemically, they are quite different from elastomers or thermoplastics. However they are generally classed with single-ply membranes. Modified bitumen's are generally applied by torch, hot asphalt or modified adhesives. Some are self-adhered (Peel & Stick). 37 Surfacings Surfacing may be applied in the factory or in the field. Factory-applied surfacings may be such things as: Liquid coating Embedded granulated minerals Laminated metal foil 38 Surfacings Ballast (rock or pavers) Mineral granules Liquid coating 39 Learning About Products By visiting a manufacturers website you can access information like: Systems: TPO, EPDM, BUR, PVC, MODIFIES Details and Drawings Specifications Safety Data Sheets Videos and more 40 Safety and Health The most important subject in your training is safe working practices. If an accident leaves you handicapped or dead, all your skill as a roofer means nothing. And it can happen to YOU in one second. 41 Safety and Health Roofing is one of the most dangerous trades. It is always among the ten industries with the highest accident rates. The odds are against you unless you work to change them for yourself. 42 Safety and Health Look at four other roofers on the job. Statistics say that you or one of these four will be injured on the job this year. That is 1 in 5—very bad odds—and only you can change them. We think of roofing in terms of falls and blunt physical trauma but hazards come in various forms. 43 Hazards Falls Sprains and Strains Burns Electrocution Hit By Objects Fires and Explosions Noise Hazardous Substance Heat and Cold UV Danger We will study roofing and waterproofing hazards extensively through out your apprenticeship. 44 Hazardous Materials There are two important things to understand about hazardous materials: The hazards vary considerably with different products. Hazards can be short term (acute) or long term (chronic). You may not notice any effects when you are working with a material, but you could be disabled from it 5, 10, or 20 years later. 45 Safety Data Sheets Review SDS to see what safety precautions are needed. What type of PPE do I need. What if I get some on my skin or in my eyes? Is it flammable? How do I extinguish a product if it’s on fire? How should I store it? 46 End of Chapter 1 Thank You 47