Energy Measure To Save

advertisement

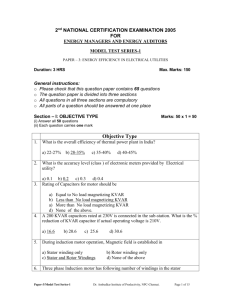

Energy Intake by the industry • Energy Losses (Between the Cup & Lip in industry) • Voltage Regulation in Stages upto Load End • Power Factor Regulation in Stages • Compressed Air – Cool Dry Air in Stages • Energy Measured • Measure Energy Digitally & Accurately from Entrance to Load End . Energy Efficiency Benefits • Reduced Energy bills – Visible Gains ! • • • • Increased Productivity – Invisible Benefits Improved Quality Increased Profits Increased Competitiveness !! • Ultimately, Machines’ Health Improves By :- Minimum Energy Input & Maximum Output - This Prolongs the life of machines & Safety - Important: We get more from machine even later Energy usage Break-up in Foundry Approximate power consumption of Major Equipments ( Typical ) • • • • • • • Total Energy input Melting Furnaces Annealing Furnaces Compressors Sand plant Other loads lighting 100 % 60 % 17.14 % 11.48 % 2.55 % 6.52 % 2.28 % ELECTRICAL DISTRIBUTION SYSTEM -- SINGLE LINE DIAGRAM EB POWER TRIVEATOR METER Metering 11 KV/440V Transformer Effi.95-98% M ELECTRICAL M DG SET Dist. loss 4 - 8% M M M M Feeders, Capacitors C C Distribution Panels Motors Effi.85-96% FANS & BLOWERS PUMPS R & AC COMPRESSORS LIGHTING, HEATING MECHANICAL C Energy Balance in Induction Furnace Material Grey Iron Crucible Capacity 3200 Kg Volts - 968 input 733 KW Production capacity 1600 Kg /hr 660 Units / Ton 100 % Input Energy USEFUL HEAT 380 Coil I2R losses 130 units / ton units / ton 58.5 % 20 % Radiation losses 97.5 Conduction losses 34 units / ton units / ton 15 % 5.2 % Unaccounted loss 18.5 units / ton 1.3 % Foundry furnace savings aspects • • • • • • • • Busbar losses - joints inpsect, overheating, discolor Pneumatic ckt - demoist, lubricate, press regulate Hydraulic ckt - oil level, filter, proper functioning Refractory lining - to check before & after melt’ Transformer - ventilation, forced, oil temp, connect’ Water ckt - quality, temperature, pressure ratings Water temp < 42 * C to prevent scale formation CT - functioning and water In /Outlet temperature monitoring etc., wooden fill > pvc fills practically. Radiation losses in foundry • Temperature - Energy loss - Energy loss *C btu/sqft/hr - kW /m2 • 555 8000 25.28 833 20,000 64.56 1115 52,000 161.4 1400 1,25,000 387.4 • Radiation – Line of sight phenomenon : Heat loss proportional to difference of 4th power of hot & cold • Practice to allow 100 –150 *C higher temp for melt to take care of heat loss in sadle & during transit • Each 1* extra temp > 1 to 2 kwh extra consume/ton • Temperature monitor by pyro & T/Couple Thermal Efficiency parameters of Induction Furnace • 3 to 10 % • 18 to 22 % • 4 to 6 % • 2 to 4 % Losses in the Electrical System in connecting the bus bars losses in Induction coil as well as the water cooled leads losses in keeping the lining hot losses in radiation etc. • 55 to 75 % Thus the Thermal Efficiency of Induction Furnace varies in the range. Flames leaping out of furnace • Two identical furnaces taken for case study • Gun metal to be melted was weighed & charged. • One furnace was operated normally by the operators by leaping out the flames outside. • Other furnace was operated by confining the flame within the furnace • Time taken to melt the charge is the same for both the furnaces; but the fuel consumption was only half. Motors – range of Losses Are we loading our motors efficiently ? Motor is a Consumable = 7.5 hp replaced by 5 hp new Motor particulars Motor rating Input voltage Volts Full load speed rpm Power factor Measured current amps Energy consumed / hr Units consumed MORE Units lost per day Units lost per month 7.5 hp std motor 5 hp E E motor 5.5 KW 400 1430 0.84 8.6 5.0 units 0.6 unit / hr 14 units 430 units 3.7 KW 400 1450 0.89 7.16 4.4 units nil nil The table below Compares the behavior of 5 H.P motor at Higher than 400 volts courtesy – Muskan Servo OEM study Input Voltage Current KVA PF 400 7.5A 5.2 0.8 425 11% More 18% More 0.7 435 19% More 28% More 0.61 445 26% More 38% More 0.57 Improved Power Factor Correction on typical 50HP Motor gives significant results. 50 HP motor Without Cap 37.3 KW 50 HP motor ( with Cap ) 36.2 KW % Change in parameters 3% Decrease 28 KVAR 15.1KVAR 46% Decrease 46.6 KVA 38.4 KVA 17% Decrease 0.8 PF 0.92 PF 15% improvement Thermal Imaging – Tool to Predictive Maintenance – Management Parameter Unbalance in current in % Increased Temp Rise *C in motor Percent unbalance in voltage 0.3 = 2 volt 2.3 = 10 volts 5.4 = 20 volts 0.4 17.7 40 0* 30* 40* Say 60 * C 60 + 30 = 90* 60 + 40= 100* Effect of Voltage Unbalance on the performance of 5 HP motor :is more detrimental to motor performance and motor life than voltage variation. Increased temp. rise is 40 *C for unbalance of 5 % Say motor temp is 60 * , then this raises to 100 * C. Hot spots motor bearing DE & NDE CONDITION MONITORING Infra red gun readings point to : • 0 to 10* C high : - Corrective measure to take during next maintenance period. • 10 to 20* C high : - Corrective measure required as scheduled Maintenance permits. • 20 to 40* C high : - Corrective measure required As Soon As Possible. • 40*C and high : - Corrective measure required immediately. Compressed air what supplied & what used ? CA system Air intake – Rupee wise, Paisa Foolish • Compr. Air intake Temp. 3*C raise, Power Up 1 % • 100 scfm @ 7 bar Annual Comp Air use Rs. 6 Lacs • Daily clean Pre Air Filter before Air intake Filter • 160 Scfm Compr. @ 7 bar at 45*C air outlet pumps 1 Litre more water in air per hour than at 35 * C Compressed Air systems – Are we Healthy ? • Don’t crack drains manually all over.Auto-drain valve with balancing pipes to be effective • Regulate at start & Demarcate HP & LP air usage & shut off the airlines when not in use • Provide large air receiver near heavy consumer to avoid shock load, fluctuations in system pressure • Filter Lubricator Regulator at end usage point to be inspected daily and oil maintained regularly. • PLMS pipe line moisture separator to be active at start and end of line, & at usage point. CA usage Efficiency Example • An open 6 mm pipe could consume about 70 CFM of air at 5.5 bar pressure which means about entire compressed air generation of 20 HP air compressor. In contrast • Energy Efficient Nozzles and jets • consumes only 20 CFM air at 5.5 bar pressure yet provides adequate thrust and air volume for most applications. Why we use air blow guns instead of blunt nylon hose ? • The flow through a leak is similar to an orifice in that the flow is determined by the pressure immediately upstream of the opening. • The pressure drops in the line supplying air to the leak based on line's ability to support rate of flow. • For example, the air flow across a 1/4" orifice at 90 psig is 94 scfm • but the flow through ten feet of 1/4" I.D. copper tube at 90 psig will be less than 40 scfm because the pressure will drop to 35 psig in the tube. Compressor takes excess power due to inadequate maintenance Worn-out piston ring, gland packing 2 – 3 % higher power Worn, broken, leaking valves 5 –6 % higher power Worn, improperly aligned bearings 1 – 3 % higher power Dirty, non recommended lube oil 1 % higher Clogged suction filter 2 – 3 % higher power Low, high temp. cooling water flow 1 % higher power per 4 *C higher water temp up to certain limit CA system efficiency improves by : • Reduction of 1 Kg/cm2 air pressure (8 Kg/cm2 to 7 Kg/cm2) results in 7% input power savings • Using solenoid ball valves wherever required • Installation of after coolers and dryers • Carrying out pump – up test, leakage test, specific power consumption determination regularly • Ensuring proper air /water cooling of compressor • 1mm scale build-up on condenser tubes increases energy consumption by 40% Compressed Air loss - Examples • Leakage @ ½”dia hole in Compressed Air line @ 7 Kgsc can drain almost Rs.2500/- per day • Hour meter on Compressor Load/ Unload Status • Compressor works like Submersible pump in air. • Cool Compressor delivers more air. • Continuously run Compressor delivers less than an intermittently run Compressor. “ we must know what we consume where ” Preliminary energy audit is a relatively quick exercise • to Establish energy consumption in the organization • Estimate the scope for saving • Identify the most likely ( & easiest areas for attention.) • Identify early ( no-/ low-cost) improvement & savings • Set a reference point / Bench mark within the machine • Identify areas for more detailed study/measurement • Preliminary audit uses existing, and easily obtained data. Energy Audit shows where we stand • • • • What to do, where to start, at what cost and for what benefits • First step is start with Preliminary Audit with existing Datas. • Second step is Detailed Audit & Generate more Parameters. • Indicative saving potential to achieve • Good House-keeping yields • Minor Investment gives • Reasonable Investment pays back 5 - 10% 10 - 15% 20 - 25% Shock, Relief & Delight • The three stages of accepting results of an energy study or audit of process & utility are • Shock, Relief and, finally, Delight ! • The general wrong opinions about Maintenance has been • "Maintenance is a necessary evil" • "Nothing can be done to improve maintenance costs” • Please remove the opinions & now Remember: • Where Safety (Conservation) Fails, Pollution Starts. • Maintenance is a Tool to Productivity • Utility to process is like Medicine in bottle to our body. • Shake bottle before use & shake our body after intake for quick & better results of medicine. FIVE COST REDUCTION MEASURES OF ENERGY CONSERVATION • Identify inefficient energy use • Upgrade machinery & process in context of energy efficiency • Improve maintenance practice • Promote employee awareness and • Conservation in domestic consumption. Tube light– variation in Light output & Power output • Particulars • Light output • Power input • • • • • • • 10% low-360 volt 10% high – 450 volts Decreases by 9 % Increases by 8 % Decreases by 15 % Increases by 8 % Take the case of your transformer without OLTC Low & High voltages are 400 to 450 volts in day & night Lighting wants safe regulated working 360 volts only Priority is towards Energy Savings in Lighting More priority is in Safety in lighting voltages Tube light life increases and inventory comes down Not only for tube lights but also for ballasts also. Conserve Energy & Serve Nation • www.pcra.org • www.energymanagertraining.com • Please go through the Govt. Website • and you will find mine & more articles on Industry • Thank You S.ASHOK, PCRA Faculty BEE certified Energy Auditor COIMBATORE – 05. cell : - 9 4 4 3 7 - 2 0 2 2 0 ID :- ashok.anbesivam@gmail.com Pl visit my site WWW.energymeasuretosave.com