Added value with VILOFT® The special fibre cross

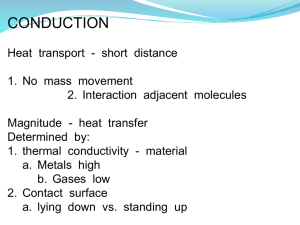

advertisement

Lenzing is marketing Viloft®, the speciality cellulosic fibre produced by Kelheim Fibres GmbH. The Kelheim fibre is now part of Lenzing’s fibre portfolio. March 2010 | 2 March 2010 | 3 VILOFT® is a premium, brandable, speciality viscose fibre from Kelheim Fibres. VILOFT® has been engineered to offer particular technical and aesthetic properties which differentiate it from other fibres. VILOFT is 100% natural in origin -it is made entirely from eucalyptus wood pulp sourced from managed plantations. Environmentally friendly fibre Eucalyptus is one of the fastest growing raw materials. VILOFT® is 100% biodegradable. VILOFT® is certified to: the Oeko-Tex Standard 100: it is free of harmful substances (certified for the most sensitive product area substances namely for use in baby applications) FSC (Forest Stewardship Council) March 2010 | 4 Environmental protection & sustainability are important for us. VILOFT® production in Germany meets all local environmental legislation and complies with all current EU requirements. What is VILOFT® The fibre has a unique flat cross-section with a crenellated surface. Magnified view of VILOFT® fibre March 2010 | 5 Added value with VILOFT® March 2010 | 6 The special fibre cross-section creates air pockets for excellent thermal insulation, quick moisture transport and breathability, which creates a comfortable micro climate next to the skin. VILOFT® transports moisture away from the skin and inhibits the growth of bacteria in a natural way. VILOFT® fibres are naturally soft and guarantee outstanding wearer comfort. Added value with VILOFT® March 2010 | 7 Yarns made with VILOFT® contain up to 70% air and fabrics using VILOFT® feel light and soft as a feather on the skin. Easy care: textiles made of VILOFT® are machinewashable. VILOFT® fibres are 100% natural in origin and are manufactured from renewable raw materials – they are also 100% biodegradable and so complete the natural cycle. Added value with VILOFT® Softness Due to its unique flat cross-section, VILOFT® creates fabrics and garments with an extremely soft handle for excellent next-to-skin comfort. Example: ribbon Flat cross-section March 2010 | 8 Low rigidity of flat cross section = increased flexibility and increased softness Example: shoelace Round cross-section high rigidity of round cross section = decreased flexibility and less natural softness Added value with VILOFT® Thermal When blended, often with polyester, VILOFT®’s engineered flat cross-section traps pockets of air to protect and insulate the skin against the cold. Flat cross-section VILOFT® original March 2010 | 9 Air pocket Added value with VILOFT® Moisture Management Moisture is transported away from the skin through the fabric by the capillary action of the VILOFT® fibre. March 2010 | 10 Tried and tested Our customers have worked successfully with VILOFT® for many years. Besides a high level of customers satisfaction recent scientific analysis by the renowned Hohenstein Institutes has proven the outstanding quality and functionality of VILOFT® speciality fibres. Flat cross-section of 100% VILOFT® yarn March 2010 | 11 Thermal Insulation March 2010 | 12 Textiles made of 100% VILOFT® show a high thermal insulation value. The flat fibre crosssection of VILOFT® produces numerous air pockets which insulate against cold. Test method: DIN EN 31 092 (02/94) resp. ISO 11 092 (10/93 Incorporation of air in VILOFT® yarns March 2010 | 13 The special crosssection of VILOFT® fibres allows the formation of considerably more air pockets in the yarn which allows the production of fabrics with an airy, light feel. Perspiration Buffering Index March 2010 | 14 Each day we are faced with stressful situations or physically demanding tasks. This leads to an increased production of sweat. Extensive tests and research at the Hohenstein Institutes have allowed the creation of a skin simulation model which has confirmed VILOFT®’s outstanding perspiration buffering properties. Standardized test norm BPI 1.2 (12/93), section 3 Water Vapour Uptake March 2010 | 15 One of the main advantages of VILOFT® is the ability to absorb moisture from the skin – this creates a comfortable dry feeling for the wearer and at the same time inhibits the growth of bacteria in a natural way. Test method: DIN EN 31 092 (02/94) resp. ISO 11 092 (10/93 Pilling Behaviour of VILOFT March 2010 | 16 Viscose garments are checked very critically regarding pilling problems. Tests carried out by a leading underwear manufacturer have shown excellent results for VILOFT®. Tested to DIN 12945-2 Cat. 3 100% VILOFT® outperformed comparable fabrics. Summary – warm and as light as a feather The flat cross section of Viloft® gives it excellent thermal insulation properties. The modified cross-section creates air pockets in textiles which act as a buffer against the cold. Textiles made of Viloft® have particularly good insulation values and provide lightweight warmth. An ideal fibre for cold weather seasons. March 2010 | 17 Summary – Superior Thermal Performance Tests demonstrate the effectiveness of Viloft® in textiles. Comparing Viloft® knit fabrics with cotton knit fabrics shows that Viloft® fabrics have up to 30% higher thermal insulation than cotton fabrics. Even at this level, the use of Viloft® is enough to make a significant difference in textile warmth. March 2010 | 18 Summary – Exceptional Comfort The unique viscose Viloft® fibre creates textiles that are particularly warm and skin-friendly. Viloft® is naturally soft, supple and breathable. In blends with synthetic fibres and wool, Viloft® ’s properties are especially beneficial since moisture absorption and softness are important comfort features. March 2010 | 19 Summary – Beautiful Warmth Excellent thermal insulation combined with softness and skin-friendliness make Viloft® ideal for applications in the intimates market. Viloft® fabrics are easy to care for and are machine washable. March 2010 | 20 Summary – Global Support Now that Viloft® is part of Lenzing’s global fibre portfolio, customers have numerous advantages. The Lenzing brand stands for service, marketing support and a global marketing team. Viloft® customers now have full access to Lenzing’s support around the world. Superior thermal performance, outstanding softness, worldwide marketing: Lenzing Viloft® - The Thermal Viscose. March 2010 | 21