Fatal Crane Incident at Amin (Nimr) Steam Pilot Project 20/09

advertisement

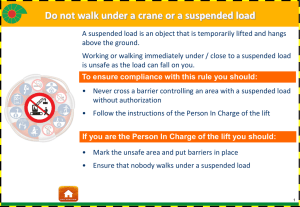

Fatal Crane Incident at Amin (Nimr) Steam Pilot Project 20/09/2012, FIM # 869548 Incident Summary A fatal incident occurred at the Amin (Nimr) Steam Pilot project site on Thursday 20th September, 2012 at an approximate time of 14:10 hrs. The deceased is a 32 year old Indian helper working for Al Turki Enterprises (ATE), a PDO contractor. An ATE mechanical crew was using a 25 ton crane to lift pipe sleeves. During the lifting operation, the deceased went to fetch slings from the crane’s tool box located above the cranes battery. The contents of the box cannot be accessed from ground level so he stood on the outrigger and reached over. In doing so he placed himself in the arc path taken by the cranes counter weight which as it rotated, crushed the deceased against the toolbox. He immediately fell unconscious and was brought to STS camp clinic in Amal. The doctor gave him CPR but could not revive him and at 15:15 hrs he was declared dead. 1 Fatal Crane Incident at Amin (Nimr) Steam Pilot Project 20/09/2012, FIM # 869548 Events leading to the Incident • There was no ‘Person In Charge’ or banksman controlling the crane operations • There were Concurrent Operations leading to conflicting tasks in the area. • 2 mechanical crews working on two separate PTWs in the same area • The deceased walked into and within the cordoned off area. • There were non adherences to the PTW requirements and deviations from the Lifting Operations Standards and Procedures (PR 1709): • lifting plan was not followed; • hazards were not reassessed when there was a change at the work site; • crew members changed from one crew to another. 2 PDO Emergency Safety Advice for all crane operators Learnings from Incident (LFI) 1. Ensure there is a proper lifting plan in place and it is followed at all times; 2. Ensure HEMP has been carried out; 3. Ensure the “Ten Questions For A Safe Lift” have been discussed and properly cascaded during the toolbox talk; (slide 6) 4. Ensure risks of concurrent operations are assessed and mitigated; 5. Ensure lifting operation personnel are competent and qualified; 6. Ensure a Person is In Charge (can be the Banksman) and wears a high visibility vest; 7. Never access a crane when it is either operating or about to operate; 8. Use steps to access heights, not an outrigger; 9. Always be aware of events around you and expect the unexpected; 10. Barricade the area and ensure only authorized personnel enter; 11. Crane drivers and banksman (signaller) must visually check all around the crane before operating. Not complying with crane Operating Procedures and Standards can kill Responsibilities Banksman / Signaler: The only person, who co-ordinates the lifting movements and maintains radio- and/or visual communication with crane operator and persons close to the load. Slinger / Rigger: The person, who inspects the rigging, selects rigging to suit the load, installs the equipment and connects/disconnects the load. Person in charge of the lifting (PIC) The person, who co-ordinates and controls all aspects of lifting operations on site. (The PIC and Banksman may be the same person). Management Learnings To ensure continual improvement all Contract Managers are to review their HSE HEMP against the questions asked below: Confirm the following: •Do you employ a competent PDO compliant banksmen used for all lifting operations? •Do you employ trained and competent crane operators? •Do you create and use lifting plans for all lifting operations? •Do you adequately supervise lifting operations? •Do you regularly audit your lifting operations to assure compliance? •Do you have an effective maintenance and inspection schedule to keep the windows/mirrors clean and alarms working? •Do your cranes have warning labeling to warn the unsuspecting of hazardous areas? •Do you conduct relevant TBTs to staff involved in lifting operations? •Have you conducted risk assessments of lifting operations and ensured the required controls are implemented and maintained? •Have you created and introduced effective Job Safety Plans for lifting operations. Ten Questions For A Safe Lift 1. Is everyone aware of and fully understands the lifting and hoisting procedures applicable to the lift? 2. Has everyone attended the toolbox talk? 3. Has a pre-use inspection of the Lifting Equipment been carried out and are the Lifting Accessories tagged or marked with: - Safe Working Load (SWL) - A unique identification number - A valid certification date 4. Are all safety devices working? 5. Does everyone know the Person-in-Charge of the lift? 6. Is everyone competent and aware of his or her tasks? 7. Is there a current Lift Plan and JHA and does everybody understand the job and precautions? 8. Does everyone know the environmental limits (e.g. maximum permissible wind speed) for the lift? 9. Is the lift area controlled and is everyone clear if the load falls or swings? 10. Are signaling methods and communication agreed and clear to you? LSR 7 Never walk under a suspended load •Every “routine” lift must have a generic lifting plan. • Every “non-routine” lift must have specific lifting plan. • Person In Charge shall ensure lift area is cordoned off during the lifting operations. • No one should ever be under any working crane or suspended load. Person In Charge (Banksman / Signaler) Fatal Crane Incident at Amin (Nimr) Steam Pilot Project 20/09/2012, FIM # 869548 Incident Details Contractor Name : ATE Incident Owner : OSD Time, Date, Place : 14.10 hrs, 20th Sep. 2012 at Amin ‘A’ Street Persons involved in the Incident : Mr. Jakhu Naran Maheshwari (ATE Emp. No. 919596), Age – 32 working as a helper in ATE since 2009 Vehicles / equipment involved in the Incident : TE – 285, 25 Tons Mobile crane, Make Kato, NK 250EV, Year of manufacture – 2001 Injuries :1 Fatality Actual Severity Rating : Level 4 Potential Severity : Yellow 9