Training

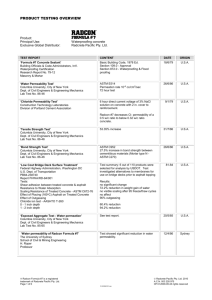

advertisement

Nuclear Power Plant Orientation Introduction to BWR Systems Browns Ferry Nuclear Plant HPT001.014D Rev. 0 Page 2 of 34 Introduction • During this phase of the training we will discuss the basic operation of a Boiling Water Reactor (BWR) Plant, including: – the major design concepts of the Browns Ferry BWR-4 and its Mark I containment – the importance of nuclear safety. • We will also discuss several of the systems associated with BFN’s operation. TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-2 HPT001.014D Rev. 0 Page 3 of 34 Enabling Objectives Identify the major components and flowpaths in the steam cycle. Recognize the functions of water in a BWR Recognize the functions of the control rods in a BWR Recognize the capability and purpose of nuclear instrumentation TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-3 HPT001.014D Rev. 0 Page 4 of 34 Enabling Objectives Identify alternate sources of emergency cooling water to the reactor vessel Relate major concepts employed in containment design Identify inherent safety features of a BWR Compare advantages and disadvantages of a BWR to that of a PWR TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-4 HPT001.014D HPT001.014D Rev. Rev. 0 0 Page of 34 Page 5 of534 $ Tennessee River 51 HPT001.014D Rev. 0 Page 6 of 34 BWR Design • Selected by GE due to its inherent advantages in control and design simplicity. • Single loop system; steam and associated secondary systems are radioactive. • Operating pressure is approximately half that of a PWR at 1,000 psi. • Capacity of units two and three is ~1,100 Mwe each. TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-6 HPT001.014D Rev. 0 Page 7 of 34 BWR Internal Flow • Feedwater enters downcomer. • Recirculation loops provide forced circulation. • Moisture removed by separators and dryers. • Steam exits steam dome. TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-7 HPT001.014D Rev. 0 Page 8 of 34 BWR Internal Flow Core 8 HPT001.014D Rev. 0 Page 9 of 34 Recirculation System Flow Path Jet Pump Risers Recirc Pump Suction Ring Header Recirc Pump Motor 9 HPT001.014D Rev. 0 Page 10 of 34 Steam Dryer installed in Reactor Pressure Vessel 10 HPT001.014D Rev. 0 Page 11 of 34 Steam Dryer stored in Equipment Pit 11 HPT001.014D Rev. 0 Page 12 of 34 Fuel Transfer Canal 12 HPT001.014D Rev. 0 Page 13 of 34 Plant Layout • The entire Reactor Coolant System (RCS) and other primary support systems are located within containment (the drywell) and reactor buildings. Main Steam, Condensate and Feedwater (all radioactive) are housed within the turbine building. The reactor is operated remotely from the control building. TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-13 HPT001.014D Rev. 0 Page 14 of 34 Main Steam System • Steam generated by the reactor is admitted to four main steam lines. • One high pressure and three low pressure turbines convert thermody- namic energy into mechanical energy to drive the main generator. • Safety objective is to prevent overpressurization of the nuclear system. TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-14 Main Steam System Flow Path HPT001.014D Rev. 0 Page 15 of 34 RPV To HP and LP Turbines 15 HPT001.014D Rev. 0 Page 16 of 34 Condensate and Feedwater Systems • Once the steam has passed through the high and low pressure turbines, it must be condensed and then pumped back to the reactor so that the cycle can be repeated. • These systems will collect, pre-heat, and purify feedwater prior to its return to the reactor plant. TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-16 HPT001.014D Rev. 0 Page 17 of 34 Condensate System Flow Path LP FW Heaters To Seal Injection Pumps A BB C Makeup Control A To 9 Cond. Demins B C Reject Control To 29A & B Reject to CST Makeup From CST 17 Feedwater System Flow Path HPT001.014D Rev. 0 Page 18 of 34 HP FW Heaters Reactor Pressure RPV Vessel Primary Containment Reactor Feed Pumps 18 HPT001.014D Rev. 0 Page 19 of 34 Fuel Cell • Currently, Framatome is the supplier of fuel for BFN. • Four fuel bundles per cell. • 764 bundles per reactor. TP-19 TVAN Technical Training Health Physics (RADCON) Initial Training Program Fuel Cell HPT001.014D Rev. 0 Page 20 of 34 Control Rod Blade 20 HPT001.014D Rev. 0 Page 21 of 34 Control Rods • Rods contain boron as the neutron absorber. • Tubes held in cruciform array by a stainless steel sheath. • 185 control rods per reactor. TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-21 Control Rod Blade HPT001.014D Rev. 0 Page 22 of 34 Note: (21) ABSORBER RODS 143" X .188" OD IN EACH SHEATH OF BLADE 22 HPT001.014D Rev. 0 Page 23 of 34 Control Rod Blades 23 HPT001.014D Rev. 0 Page 24 of 34 Nuclear Instrumentation Three ranges of neutron monitoring; all in-core. • Source range - 0.1 to 106 cps • Intermediate range - 104 cps to 40% power . • Power range - 1 to 125% power. TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-24 HPT001.014D Rev. 0 Page 25 of 34 Nuclear Instrumentation BOTTOM OF TOP GUIDE DETECTOR CHAMBERS LENGTH OF ACTIVE FUEL CORE SUPPORT REACTOR VESSEL IN-CORE HOUSING GUIDE TUBE REACTOR SUPPORT STRUCTURE 25 HPT001.014D Rev. 0 Page 26 of 34 EMERGENCY CORE COOLING SYSTEMS (ECCS) • Prevent fuel cladding fragmentation for any failure including a design basis accident. • Independent, automatically actuated cooling systems. • Function with or without off-site power. • Protection provided for extended time periods. TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-26 HPT001.014D Rev. 0 Page 27 of 34 EMERGENCY CORE COOLING SYSTEMS (ECCS) • High Pressure Coolant Injection (HPCI) • Low Pressure Coolant Injection (LPCI) • Core Spray • Automatic Depressurization System TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-27 Emergency Core Cooling Water Sources HPT001.014D Rev. 0 Page 28 of 34 Condensate Storage Tanks ~2,000,000 gal Normal Systems CONDENSATE FEEDWATER CONTROL ROD DRIVE Reactor Emergency Systems HIGH PRESSURE COOLANT INJECTION CORE SPRAY LOW PRESSURE COOLANT INJECTION Torus ~950,000 gal RHR SVC WATER FIRE PROTECTION Tennessee River 28 HPT001.014D Rev. 0 Page 29 of 34 Primary and Secondary Containment • Primary Containment consists of the Drywell and Suppression Pool (Torus). • Secondary Containment consists of the Reactor Building. • Designed to contain the energy and prevent significant fission product release in the event of a loss of coolant accident. TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-29 Containment Design HPT001.014D Rev. 0 Page 30 of 34 • Structural Strength - steel structure with reinforced concrete able to withstand internal pressure. • Pressure Suppression - large pool of water in position to condense steam released from LOCA. • Designed to contain the energy and prevent significant fission product release in the event of a loss of coolant accident. TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-30 HPT001.014D Rev. 0 Page 31 of 34 Primary and Secondary Containment Drywell Torus 31 Advantages of BWRs HPT001.014D Rev. 0 Page 32 of 34 • Single loop eliminates steam generator • Bottom entry control rods reduce refueling outage time/cost; also provide adequate shutdown margin during refueling. • Lower operating pressure lowers cost to obtain safety margin against piping rupture. • Design simplifies accident response. TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-32 Disadvantages of BWRs HPT001.014D Rev. 0 Page 33 of 34 • More radiation/contamination areas; increased cost associated with radwaste. • Piping susceptible to intergranular stress corrosion cracking (IGSCC). • Off-gas issues (e.g. - H2 gas presents explosion potential, low levels of radioactive noble gases are continuously released). TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-33 Summary HPT001.014D Rev. 0 Page 34 of 34 • A Boiling Water Reactor plant is comprised of many different and complex systems, all of which support the overall goal of safely producing electricity. • The design challenge of a BWR is to incorporate all the criteria of power generation and safety in non-conflicting ways in order to meet the load demand of the public and satisfy the requirements set forth by the Nuclear Regulatory Commission (NRC). TVAN Technical Training Health Physics (RADCON) Initial Training Program TP-34