Amorphous Silicon Thin Film PV System

advertisement

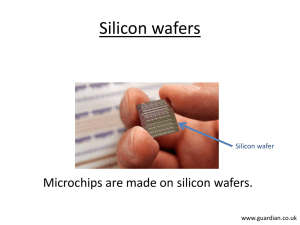

Lamma Power Station Solar Power System Content Project Background Site Selection Amorphous Silicon Thin Film Photovoltaic System Environmental Benefits Challenges Project Schedule Summary and Way Forward 2 Project Background To widen the use of renewable energy in HK Electric’s power generation system in support of government policy. To explore the introduction of commercial scale solar energy project following the success of commissioning the first wind turbine in providing green electricity. To partner with DuPont Apollo Limited in studying the feasibility of installing large scale PV System in Lamma Power Station. 3 Site Selection - Considerations Large flat area for solar PV installation on ground or roof top The total weight of solar panels and supports against allowable roof loading Orientation of solar panels – facing south and tilted at 22º Full utilization of sunlight with no shading Visual impact Ease of grid connection Accessibility for operation & maintenance 4 Site Selection - Installation Locations 5 groups on rooftops of Main Station Building & 1 group near C.W. Intake no. 2 5 Amorphous Silicon Thin Film PV System – Technical Information Amorphous silicon photovoltaic module – 5,500 pieces Total Area of PV modules – 8470 m² Maximum output of each PV module – 100 W Total installed Capacity – 550 kW Capacity Factor – 12.9% Anticipated power output – 620,000 kWh Design life – 20 years Project Cost – HK$23 million 6 Amorphous Silicon Thin Film PV System – Characteristics and Benefits 1. Use less energy for production The more silicon is used for production of PV panels, the more energy is required. Thin film PV technology uses less silicon. Thickness is only about 1/200 of that for crystalline PV module. 2. More suitable in tropical environment Thin film PV maintains better power output level at high temperature than crystalline PV. 3. Better weak light performance Thin film PV modules are able to effectively produce power at low irradiance conditions. 7 Amorphous Silicon Thin Film PV System – Power output in response to solar irradiance variation Output (kW) Irradiance (W/m²) 1000 1000 900 18/07/2010 (Sunny) - Output 900 800 22/07/2010 (Cloudy & Rainy) Output 18/07/2010 (Sunny) - Irradiance 800 700 600 22/07/2010 (Cloudy & Rainy) Irradiance 500 700 600 500 400 400 300 300 200 200 100 100 0 0 Time Power Output: 18/7/2010 (Sunny) – 3,582 kWh, 22/7/2010 (Cloudy & Rainy) – 1,258 kWh 8 Amorphous Silicon Thin Film PV System – Operation & Maintenance ● Fully Automatic Operation With solar irradiance of 100 W/m² and the output voltage of PV string at 360V, the system connects to the grid automatically. ● Simple Maintenance General cleaning required under normal circumstances. Power output not affected even with minor cracks on surface of PV modules. 9 Environmental Benefits Reduce 520 tonnes of CO2 emission per annum Reduce 2.9 tonnes of SO2 emission per annum Reduce 1.4 tonnes of NOx emission per annum 10 Challenges 1. Retrofitting large scale solar power system in existing power plant – locating large flat areas without any shade to set up PV modules, while not affecting plant operations. 11 Challenges 2. Mounting the PV panels firmly at the selected sites without damaging water-proofing layers on rooftops and wind pressure on PV panels. HK Electric’s Solar Power System Typical Mounting of modules Metal structure fixed by anchored bolts Wind Pressure 2.4 kPa / m² (No stiffeners) Concrete blocks freely stand on the roof to avoid damage to water-proofing layers 5.6 kPa / m² (Stiffeners added) 12 Challenges 3. Delivering large quantities of equipment and materials to rooftops. 5,500 Solar Panels 47 PV inverters, 47 combiner boxes, 25 Electrical and instrument panels 100,000 metres of cables and cable supports 21,888 angle steel brackets for fixing of PV modules onto the concrete blocks 11,000 concrete blocks for fixing of PV modules 250 Ton crane for lifting of materials to EL+80.15 roof areas 13 Project Schedule 4 – 9/2009 Site investigation and study 10 & 11/2009 Tendering 12/2009 – 3/2010 Design 4 – 6/2010 Construction, testing & commissioning End 6/2010 Project Completion 14 Summary and Way Forward ● ● ● It is the largest solar energy system in Hong Kong. More solar panels are planned to be installed on the rooftops of the New Store Building and existing 275 kV Switching Station. The long term target is to expand the total capacity of the system to 1 MW. 550 kW Lamma Power Station Completed in 2010 Amorphous Silicon Thin Film 350 kW EMSD Headquarter Completed in 2005 Crystalline Silicon 198 kW Hong Kong Science Park Completed in 2005 Crystalline Silicon 15 Thank You