6 Spare part Management

advertisement

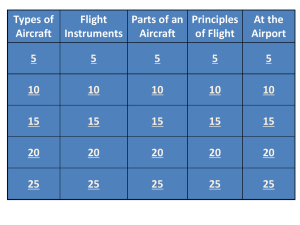

Section 6 AIRCRAFT MAINTENANCE Initial Provisioning (Spare parts Management) 1 Apr-15 Production Planning and Control “Plan your work and then work your plan.” 2 Apr-15 Production Planning and Control Production planning and control (PP&C) is one of the key organizations within M&E. It is the heart of the maintenance organization. The PP&C organization is primarily responsible for planning and scheduling all aircraft maintenance activity within the airline. Actually PP&C has three primarily functions: forecasting, planning and control. 3 Apr-15 Forecasting Forecasting activities include the estimated maintenance workload for the long term and the short term based on the existing fleet and business plans and on any known changes in these for the forecast period. Forecasting is concerned with the future workload of the M&E organization. It must take into account the routine maintenance requirements as well as all planned changes in the future operations relative to maintenance. Any changes in fleet size and make up, changes in route structure, and changes in facilities, manpower, and skill requirements must be tracked. Future plans must also accommodate aging and replacement of equipment, adding new equipment, and the planned incorporation of ADs and SBs. 4 Apr-15 Forecasting Forecasts are usually made for the long and short term but often an intermediate term forecast is also made. - Short-term forecasts are more detailed and usually cover 1-2 years. These forecasts contain more definitive plans with attention to actual manpower and budget numbers. - Long-term. Larger airlines may also develop intermediate forecasts for periods of 2 to 5 years. 5 Apr-15 Production Planning & Controls Planning involves the scheduling of upcoming maintenance and includes the planning and scheduling of all manpower, parts, facilities, and time frame requirements for such maintenance: less than “A” check items, daily checks, 48-hour checks, transit checks, and letter checks (A, B, C, etc.). These plans would include incorporation of SBs, SLs, and ADs as well as other modifications deemed necessary by the airline. Coordination with flight operations and with ground handling and support activities is also included in the planning effort. 6 Apr-15 Feedback for planning - What the planners need to know to adjust future plans are the following: 1. The amount of time required to perform each task 2. The amount of time lost in waiting for delivery of parts and supplies 3. The down time for unusual circumstances 4. The additional time required for non-routine findings 5. The variation in manpower availability 6. Lost time due to parts robbing from other jobs (or from the aircraft in check) 7 Apr-15 The need of Spares An airline sells speed safety and regularity An aircraft is a highly complex device It is expected to operate at 99% + Technical regularity It is expected to fly up to 15 hours per day and sometimes even more It is expected to fly 4000 hours per year Without a readily available stock of spares these targets will not be met A two hours delay costs around 4000$. A cancellation around 16,000$ Plus The damage to a company’s image 8 08/04/58 Reliability / Consumption Data MTBF : Mean Time Between Failure MTBUR : Mean Time Between Unscheduled removals TAT : Turn Around Time [Time in days from equipment failure to it being available, serviceable again to the airline] In a given Fleet MTBF = Number of equipment hours flown MTBUR = 9 Number of Hard failures Number of removals of equipment considered faulty Number of equipment hours flown 08/04/58 Sources of Spares From the aircraft manufacturer One stop shopping Good pressure on suppliers Reduced administration load Equipment matches the aircraft Make up charged From the equipment supplier Negotiate special deals No mark up Heavy administration 10 08/04/58 Sources of Spares From second hand dealers Low prices Immediate availability Doubts on history May need early overhaul Pooling Schemes Reduced capital investment Pay from cash flow Possible availability problems 11 08/04/58 Different types of Spares 12 No-Go Essential to be operational for the aircraft to be dispatched Go-If Can be failed and the aircraft allowed to be dispatched if some reservations are met Go Can be failed and the aircraft can be dispatched. To be changed or repaired at the first (sometimes defined) opportunity 08/04/58 Typical Figures for Spares Potential A320 Example : Number of removable part numbers 25000 Number of structure part numbers 15000 Number of standard part numbers 9000 Number of equipment part numbers 1100 13 08/04/58 How can Initial ProvisioningCost be reduced? CASH FLOW Lease spares Join pool scheme as a user only Purchase only as need arises Spares included in a larger support scheme from a third part or airline service provider 14 08/04/58 Pooling Basic principle is to take advantage of scale effects. The larger 15 the fleet the smaller the expenditure per aircraft on spares becomes. Members contribute spares or capital However at about 20 aircraft the effect begin to become less noticeable Demand is random and so the pool may empty a particular time Not all prospective candidates are welcome in a pool Costs may be high. 1/365 of book value per day is common and this may be higher for longer leases by occasional users Repair costs are to be added 08/04/58 Lease and Exchange Schemes Lease Schemes Spares are leased against a fixed percentage of their cost in much the same way as are aircraft. However, because of the higher risk and administration load, required rates are higher. -1.6% - 1.7% - per month is normal At the end of the lease the equipment does not belong to the airline Exchange Schemes Instead of repairing and item a serviceable unit is given in exchange The exchange unit may be newer or older than that for which it is exchanged. There may be cash/cost adjustments Maybe difficult in some areas of the world due to extra customs charges 16 08/04/58 Package Schemes The major players – big airlines, airframe manufactures and engine companies are looking at spares repair and leasing packages. A “spares by the hour” approach User would pay a fixed or pre-determinable fee ensuring replacement of failed items by serviceable ones Main Advantage are 17 Reduced capital expenditure Easier budgeting Reduced administration Reduced risk from random need for spares Sometimes attached to an overall support scheme, particularly by airlines – “Big Brother” 08/04/58 Non availability of Spares Loss of service Extension of overhaul downtimes Cost of spares loaned or purchased hurriedly Lease of aircraft Damage to company image 18 08/04/58 A.O.G. System A.O.G. Aircraft On Ground Literally it means the aircraft cannot operate because of 19 damage or an equipment failure Often used when the aircraft is close to such a condition The manufacturer is expected to react within a minimum period of time to advise of and take action It costs much more than normal shipping It occasionally carries a surcharge Its abuse costs the industry a lot of money – The innocent pay for the guilty 08/04/58 Parts and Materials Information Approved parts is one that meets approved design data 20 applicable to the part and having been manufactured and subsequently maintained in accordance with the requirements of the State of Design, Manufacture or Registry, as applicable. Standard parts are approved parts conforming to national or industry accepted standard. Parts and material acceptance: The process of evaluating parts and material for acceptance involves establishing that the part/material is authentic, conforms to the relevant type design, customers order, physical state and accompanying release documents. Apr-15 Parts and Materials Information Unapproved Parts: These are parts that do not meet the criteria, they also include parts improperly returned to service. Original Equipment Manufacturer (OEM) parts OEMs are the primary source of approved parts 21 Apr-15 Parts Manufacturer Approval (PMA) Parts Manufacturer Approval (PMA) is a combined design and production approval for modification and replacement articles. It allows a manufacturer to produce and sell these articles for installation on type certificated products. FAA Orders 8110.42 and 8120.2 prescribe the approval procedures for FAA personnel and guides applicants in the approval process. 22 Apr-15 OEM vs PMA Compatibility, Price and Availability Customer Bases The Airlines The Cargo Carriers The Military The Commercial and Business Operators The GA Community 23 Apr-15 OEM vs PMA The Battle Wages On The war between the PMAs and the OEMs is a heated one. And even though there seems to be revenue enough to go around today, more contenders and products enter the market every year, causing everyone to worry about their own market share. Ironically, there are even some cases of combatants defecting. 24 Apr-15 Approved technical stores Approved technical stores comprise of Quarantine and Bonded stores. Quarantine stores Quarantine Store - Incoming: Provide storage for incoming material and parts. Quarantine store – Unserviceable: Provide storage for parts and material awaiting investigation and dispatch for repair. Bonded stores Bonded store: Provide storage of parts and material that have been proved authentic. 25 Apr-15 Approved Technical Stores The approved technical stores will be contained in the user manual which could be a stand alone document or part of the GMM/TPPM/MPM / MCM and will address the following: a ) Quarantine and Bonded stores; b) Incoming and outgoing inspections; c) Shelf/storage life; d) Records control; e) Parts identification ( markings); f) Storage of instruments, tools, rubber items etc; g) Segregation of parts and materials in the bonded store; h) Storage facility; i) Special storage. 26 Apr-15 Parts and Material Authenticity Evaluation Involves establishing that the parts and material conforms to approved design specifications, and have retained the essential properties assumed in the design as qualified by the supporting documents. Information on the supporting documents shall include the following: a) The authority under which they are issued; b) Reference identification for the purposes of traceability; c) Name, address and approval reference of the issuing organization; 27 Apr-15 Parts and Material Authenticity Evaluation d) Work order, contract or invoice number; e) Quantity, description, part numbers and, if applicable, serial numbers of the parts; f) Relevant information concerning any shelf life limitations, special storage condition requirements, compliance or noncompliance with any airworthiness directives, etc; g) The signature and approval reference of the person issuing the document; and h) Whether the part is new or used. 28 Apr-15 Materials and Parts Management 29 Apr-15 Tags 30 Apr-15 More Details More information please going through “Aviation Maintenance Management, chapter 16 Materiel Support” by Harry A. Kinnison, Ph.D. or Any questions please contact samrit.aero@gmail.com 31 Apr-15 32 Apr-15