ARPT Residential Air Handler

advertisement

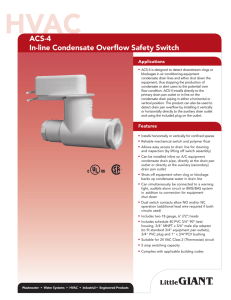

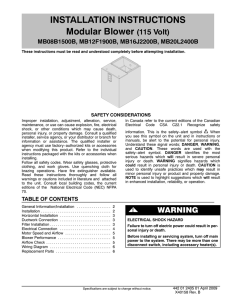

RESIDENTIAL AIR HANDLERS AR SERIES AR Nomenclature AR MULTI POSITION ELECTRIC AIR HANDLER COOLING CAPACITY 18 - 1-1/2 TONS 24 - 2 TONS 30/32 - 2-1/2TONS 36 - 3 TONS 42 - 3-1/2 TONS 48/49 - = 4 TONS 60 - 5 TONS 18 1 SINGLE PHASE AR RESIDENTIAL AR Multi-position electric air handler • Versatile up flow, right or left horizontal, and counter flow multi-position • May be located in closet, utility room, attic, or basement • Equipped with a check flow rater for Heat pump and Cooling Unit Operation • Power supply entry at top Airflow Orientation *Horizontal Right Discharge Tube and Drain conn. front Downflow discharge (with plastic vertical pan only) Horizontal Left Discharge Tube and Drain conn. front Important: Remove the horizontal pan when unit is installed in unconditioned i.e. (Garage, Attic) application, or downflow applications, and install insulation kit on vertical (donut shape) drain pan. Insulation kits should be ordered as follows: DPI 18-30/20 (AR18-32) DPI 36-42/20 (AR36-42) DPI 48-61/20 (AR48-61) *Upflow Discharge AR Air Handlers • All air handlers use direct drive motors. Power supply is 208/230 Volts, 60 HZ, 1 Phase • AR is designed for zero (0”) inch clearance, however, adequate access for service or replacement must be considered Refrigerant tubing • Refrigerant tubing should be installed as to avoid undue stress. • Suction tube should be insulated with a closed cell insulation and the seams sealed Condensate Removal • AR air handlers employ a drawthrough coil, therefore a trap must be installed in the drain lines. • A “P” trap is required. • Precautions must be used not to over tighten the adapter at the drain pan connection. • A joint compound should be used to prevent leakage and act as a lubricant. • All condensate drain lines and drain traps should be adequately insulated. • The unit and the auxiliary drain pan must be adequately elevated to insure proper drainage. Condensate Removal Electrical connections • Copper wire is recommended for all electrical connections. • 24 Volt thermostat connections • Goodman Cooling and Heating thermostat part number is CHT18-60. • Goodman Heat Pump thermostat part number is HPT18-60. Electronic Controls Blower Fan Controls Goodman Part #: B1370735 Operating Tolerances & Ranges • +80 to -40 Degrees Celsius (+176 to -40 F) • 5% to 95% R.H. Non-Condensing • 18 to 30VAC Control Voltage • Frequency - 60Hz/50Hz • Approved to UL353 Normal Operation • Blower On Delay – “G” Input Energizes – Blower Motor energized after a 7 second delay • Blower Off Delay – “G” Input De-energizes – 65 Second Delay before Blower Motor turns off. • Field And Factory Speedup Test Mode – If “R” applied to “SPEEDUP” Terminal • Both “G” Delay Timings On & Off are Immediate – If “C” applied to SPEEDUP Terminal • Delay On Timing is 3 Seconds • Delay Off Timing is 5 Seconds Field Returns • Handling Boards by Edges or Use ESD Ground Strap • Boxes or Bags for Field Returns • No Repeated Control Change-out • Moisture Control in Board Area • Return Tag Information Ground Check • Meter set to Ohms or Resistance Setting • Place Meter from GROUND quick connect to chassis ground • Reading should be near Zero ohms • Issue: GROUND Quick Connect Loose ; causes board resetting when blower starts • Issue: Flame Sensing problems if improper grounding in system Low Voltage Wiring 10 KW and Below Low Voltage Wiring 15 KW and Above Low Voltage Wiring for Heat Pumps 10 KW and Below Low Voltage Wiring for Heat Pumps 15 KW and Above Orifice Change • The restrictor (orifice) included in this unit should match the comparable capacity of the outdoor unit. • The restrictor (orifice) should be replaced before any tubing connections are made. • The capacity of the outdoor unit should never exceed the capacity of the indoor unit. ORIFICE CHANGE OUTS any questions? Thank you!