Section 6

advertisement

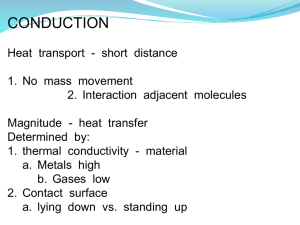

Section 6: Heat Transfer - Part II 1 Introduction to organisation of course and Field Course 2 Revision of Simple Economic Analysis 3 Thermal comfort: physical and physiological aspects. What temperatures do we actually need? 4 Energy use by sector: 5 Energy GDP relationships: Energy Balance Tables. 6 HEAT TRANSFER: U Values 7 Heat Losses from Buildings – Effect of Built Form: Dynamic Effects 8 Introduction to Energy Management 9 Energy Management Continued: Energy Targets: Building Regulations 10 Electricity Conservation 11 Thermodynamics 12 Combined Heat and Power 13 The Heat Pump 14 Energy Conservation Measures at UEA 15 Energy Analysis: - order may be swapped with section 9 Concluding Remarks ENV-2D02 (2006):Energy Conservation – power point versions of lectures. Will be available on WEB later in Week Main Objective of the Lecture • To apply the basic ideas of Heat Transfer from previous lecture to estimating the thermal properties of typical building materials. • To provide the tools to allow Heat Loss Estimations from buildings to be made [covered in next lecture ] • >> hence to estimate potential savings. Summary of Last Lecture – Key Point • Heat is lost from a building by: • Conduction Resistance to Heat Flow Estimated by where • But heat is also lost by: • Convection • Radiation from the wall surfaces d d k k k is conductivity of material d is thickness plaster External boundary layer brick Internal boundary layer Surface Resistance • Analysis of heat flow by convection and radiation is more complex. • Can be approximated in most situations for buildings by additional resistance layers. • Cannot be used if surface temperature are substantially different from surrounds – e.g. a hot water pipe/radiator. Consequences of Boundary Layers • Surface Temperature of window (on room side) is BELOW room temperature - for single glazing it will be about 70C if outside temperature is 0oC and internal temperature is 20oC • External surface temperature will be above surrounding air. • Internal Surface Temperatures are important as they affect Mean Radiant Temperature and hence Thermal Comfort. • External Surface Temperatures can affect weathering properties of bricks. 6.5 Internal and External Surface Resistances Typical values for surface resistances (m2 oC W-1): Vertical Heat Flow 0.11 for upward flow through floors/roof 0.15 for downward flow through floors Horizontal Heat Flow Rint = Rext = 0.123 0.08 0.06 0.03 internal surface sheltered external surface normal severe Note: - the orientation of windows is important in heat loss calculations as the external resistance is a significant proportion of the total resistance; 6.6 Resistances of Air-Spaces - thermal conductivity of air-spaces is very small, and heat transfer is mostly by radiation and convection, - values are given in tables, but can be divided generally into two categories:- • unventilated air spaces (or low ventilation) – • resistance is about 0.18. Examples:• air-space in modern cavity walls, • air-space in double glazing, • air-space between ceiling & underside of felt (post-war houses). • ventilated air spaces – • the resistance is about 0.12. Examples:• older cavity walls and air-space between ceiling and underside of tiles (pre-war houses). 6.7 Derivation of 'U'-values for 3 types of wall • • • • • • • • • • Many standard constructions have Uvalues in Tables Non-standard constructions do not – including many new types. Example 1 6 components:1) external surface layer 2) outer brick layer 3) cavity 4) inner brick layer 5) plaster 6) internal surface layer Internal surface resistance External surface resistance cavity brick Fig. 6.6 Heat flow through wall of 1950's construction conductivity of brick = conductivity of plaster = 1.0 Wm-1 oC-1 0.7 Wm-1 oC-1 plaster brick 6.7 Derivation of 'U'-values for 3 types of wall d • Resistance = k where k = conductivity d = length of heat flow paths (thickness in this case) • • resistance of brick = resistance of plaster = 0.11 1.0 0 . 013 0. 7 = 0.11 m2 oC W-1 = 0.02 m2 oC W-1 • Effective resistances of air spaces are:internal boundary 0.123 m2 oC W-1 external boundary 0.055 m2 oC W-1 air-cavity 0.18 m2 oC W-1 • • So total resistance = 0.055 + 0.11 + 0.18 + 0.11 + 0.02 + 0.123 • = 0.598 m2 oC W-1 =========== 6.7 Derivation of 'U'-values for 3 types of wall Total Resistance = 0.598 m2 oC W-1 • since U = 1 R • U = 1.67 W m-2 oC -1 • Note: that the external resistance is relatively small < 10% of total resistance U value for walls varies little with exposure normally [only a few per cent at most]. Example 2 • As example 1 except that the inner brick leaf is replaced by an aerated block wall i.e. construction used from mid-1960's. • • conductivity for aerated block = 0.14 Wm-1 oC-1 and resistance of such a block = 0.76 m2 oC W-1 • replaces the inner brick of original wall, • new resistance • so U-value = 0.598 + 0.76 - 0.11 = 1.248 m2 oC W-1 = 1 R = 0.80 Wm-2 oC-1 i.e. a 50% saving in the heat lost through the walls of a house. cavity brick plaster brick block Example 3 • As example 2 except that cavity is filled with insulation • conductivity of insulation • resistance of cavity fill = 0.04 Wm-1 oC-1 = d 0.05 /0.04 1 R k = 1.25 m2 oC W-1 • • replaces the resistance of 0.18 from the air-cavity New resistance = 1.248 - 0.18 + 1.25 = 2.318 m2 oC W-1 • and U-value = 1 R = 0.43 Wm-2 oC-1 • i.e. approximately half of the value in example 2 and one quarter of the value in example 1. • [the U-value for a wall with two brick leaves and cavity insulation is 0.60 Wm-2 oC-1]. plaster block brick Filled cavity cavity Example 4: Single Glazing • conductivity of glass • i.e. resistance = 1 Wm-2 oC-1 = 0.003 m2 oC W-1 (for 3mm glass) – internal surface resistance = 0.123 – external surface resistance = 0.055 • Thus total resistance = 0.123 + 0.003 + 0.055 • • = 0.181 m2 oC W-1 and U-value = 5.5 Wm-2 oC-1 Note • resistance of glass makes very little contribution to the overall resistance • if the external resistance changes (from exposure) then the U-value will also be affected significantly. • [Compare this with the situation for the walls (see note to example 1)]. Temperature Profile through a wall • Example 2 with polystyrene layer on inside • Temperature gradient is highest in insulating materials Temperature (deg C) • Assumes internal temperature is 20 oC and external temperature is 0oC 20 15 10 5 • Greatest in polystyrene layer • External Surface Temperature = 1.17 0 0 100 200 300 400 Distance (mm) 500 • If this falls below 0oC – danger of ice forming and causing Without polystyrene, surface bricks to crumble. temperature would be around 1 0C lower And PMV would be approx -0.15 lower Example 6: Pitched Roof Resistance ( m2 oC W -1) Component internal surface resistance plasterboard fibre glass (25mm) fibre glass (50mm) fibre glass (100mm) fibre glass (150mm) air-space to underside of felt felt (4mm) air-space between felt and tiles tiles external surface resistance) 0.11 0.06 0.72 1.43 2.86 4.29 0.18 0.11 0.12 0.04 0.04 Heat Flow: Internal surface resistance > plasterboard > felt > Felt – tile airspace > tiles > Loft space > External surface resistance > Example 6: Pitched Roof Resistance to heat flow Vertical Internal surface resistance Plasterboard Loft space Total vertical Inclined Felt Air space felt – tiles Tiles External surface Total Inclined m2 oC W-1 = 0.11 = 0.06 = 0.18 = 0.35 = 0.11 = 0.12 = 0.04 = 0.04 = 0.31 Total Resistance (if A = 45o) = 0.35 + 0.31 cos 45 = 0.57 A U – value = 1 / R = 1.75 W m-2 oC-1 Pre-war houses do not have felt Some houses in extreme weather areas have boards instead of felt Example 6: Pitched Roof Simple Way to examine effects of insulation U value without insulation = 1.75 W m-2 oC-1 Resistance = 1 / 1.75 = 0.57 m2 oC-1 Add 50 mm of insulation conductivity 0.04 Additional resistance = 0.05 / 0.035 = 1.43 A New total resistance = 1.43 + 0. 57 = 2.00 New U-Value = 1 / 2.0 = 0.5 W m-2 oC-1 With 100 mm New total resistance = 2.86 + 0. 57 = 3.43 New U-Value = 1 / 3.43 = 0.29 W m-2 oC-1 With 150 mm New U-Value = 0.21 W m-2 oC-1 Doubling insulation does not half heat loss Example 7 Double Glazing m2 0 C W 3mm single pane - resistance 0.003 4mm single pane - resistance 0.004 internal surface resistance 0.123 external surface resistance 0.055 air-space resistance • U values 3mm glass = • 4mm glass = -1 0.18 1 0.123 0.003 0.055 1 0.123 0.004 0.055 5.52Wm 2 0 5.49Wm C 2 0 C • little difference irrespective of what thickness of glass is used. • Double glazing: • U value (3mm glass) = 1 0.123 0.0030.18 0.003 0.055 2.75Wm 2 0 C • Note the U value depends on the thickness of the air-space, which is optimum at about 18-20mm. 6.9 Problems associated with thermal bridging Thermal bridging leads to: • cold spots on the internal surfaces • condensation • discolouration where the presence of bridges can be seen. A thermal imaging camera can be used to identify such bridges, but these are often expensive. Insulating the loft in UK houses • Place fibre glass between the joists. • As the thickness of insulation increases problems of thermal bridging appear. • timber joists create a thermal bridge Thermal bridging – an example • What is effective resistance of joists and insulation? d insulation A insulation rinsulation . k insulation A total rtimber d timber k timber • In example, insulation occupies 8/9th of space (400/450) • Heat flows are in parallel so use formula 1 Reffective 1 0.14 rtimber . 1 0.100 9 . A timber A total Insulation (150 mm thick) 400 mm 1 100 mm rinsulation 0.04 . 8 0.150 9 joists 0.393 50 mm i.e. R = 2.45 cf 3.75 if bridging is ignored Next Lecture Heat Losses from a House • Need to work out U-values and area for: – – – – Walls Windows Roof Floor • Other sources of heat Loss – Ventilation Remember: • you cannot eliminate heat losses – you can only reduce them. • Heat lost must be replaced by heating device