Lecture 17

advertisement

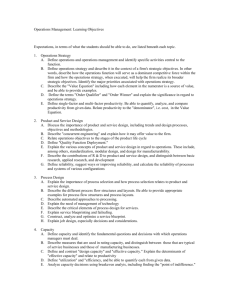

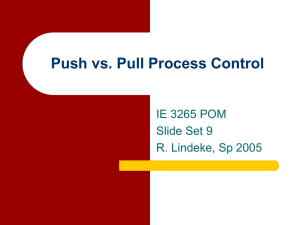

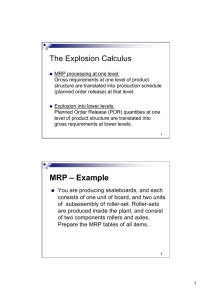

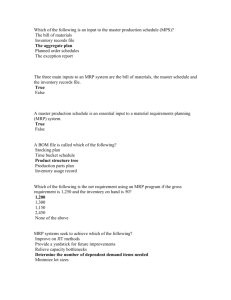

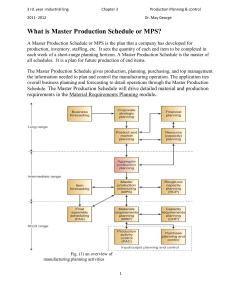

ISEN 315 Spring 2011 Dr. Gary Gaukler Dependent Demand Effective use of dependent demand inventory models requires the following 1. 2. 3. 4. 5. Master production schedule Bill of material (BOM) Inventory availability Purchase orders outstanding Lead times Time-phased Product Structure Must have D and E completed here so production can begin on B Start production of D 1 week D 2 weeks to produce B 2 weeks E A 2 weeks 1 week E 1 week 2 weeks G C 3 weeks F 1 week D | | | 1 2 3 | | 4 in weeks 5 Time | | | 6 7 8 Lot Sizing For MRP Systems Assumptions: • Consider only one item • Demand known and deterministic • Finite horizon • No shortages • No capacity constraints Lot Sizing For MRP Systems Problem formulation: Lot Sizing: Silver-Meal Heuristic In any given period, produce to cover demand in a future period as long as the average cost per period is reduced by doing so Algorithm: 1. Start in period 1. Calculate C(t): average per-period cost if all units for next t periods produced in period 1. 2. Select lowest t such that C(t)<C(t+1): t* 3. Produce enough in period 1 to cover t* 4. Repeat, starting from period t*+1 Silver-Meal Example Assume net requirements are 18, 30, 42, 5, 20 Setup cost for production is $80 Holding cost $2 per unit per period Production Schedule Changes • • • So far, the MRP examples we discussed were static In reality, we need to update our production plans as time passes, thus MRP plans become dynamic The widest-used technique involves “rolling horizons”: Production Schedule Changes • • • Using rolling horizons can lead to fluctuations in the production schedule As we include more and updated information (e.g., demand forecasts) in each period, our production schedule can change This is called “system nervousness” Production Schedule Changes • Results of fluctuations: – • • Planning for capacity utilization becomes difficult Fluctuations become larger when we re-run MRP more often But: re-running MRP is our only way of incorporating more information! Shortcomings of MRP Shortcomings of MRP MRP II Just-in-time and Lean Production Goal of Lean production: Supply the customer with their exact wants when the customer wants it without waste Method: JIT JIT is a philosophy of continuous and forced problem solving JIT: continual improvement, pull system Waste Reduction Waste is anything that does not add value from the customer point of view Storage, inspection, delay, waiting in queues, and defective products do not add value and are 100% waste Waste Reduction Faster delivery, reduced work-in-process, and faster throughput all reduce waste Reduced waste reduces room for errors emphasizing quality Reduced inventory releases assets for other, productive purposes Variability Reduction JIT systems require managers to reduce variability Variability is any deviation from the optimum process Less variability = less waste Inventory hides variability Reduce Variability Inventory level Process downtime Scrap Setup time Quality problems Late deliveries Reduce Variability Inventory level Process downtime Scrap Setup time Quality problems Late deliveries Enabling JIT: Pull System A pull system uses signals to request production and delivery from upstream stations Upstream stations only produce when signaled System is used within the immediate production process and with suppliers Experiment Reduce Lot Sizes Q1 When average order size = 200 average inventory is 100 Inventory 200 – Q2 When average order size = 100 average inventory is 50 100 – Time Reduce Setup Costs High setup costs encourage large lot sizes Reducing setup costs reduces lot size and reduces average inventory Setup time can be reduced through preparation prior to shutdown and changeover Implications for Manufacturing Reduced space and inventory With reduced space, inventory must be in very small lots Units are always moving because there is no storage